Optimum screening performance, even with the most difficult bulk materials

Schenck Process presents FlexaClass SFX, one of its new generation of flip-flop screen machines. This innovative product from Schenck Process is designed to meet the requirements created by the use of changing quality criteria in steelworks, mines, quarries, gravel and sand manufacturing facilities and power stations. Due to the increasing proportion of fine elements in bulk materials and an increase in moisture to >12 %, conventional banana and linear vibrating screens are reaching the limits of their effectiveness and designs. Moist materials stick to the screen panels and lead to blockages. Greater material fineness exacerbates this problem. As a result, effective screening is no longer possible, and even modified (self-cleaning) screen panels only have a moderately greater range of applications.

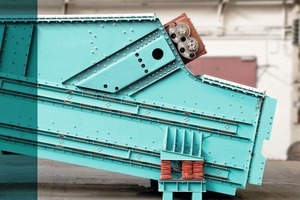

For this kind of materials Schenck Process offers the FlexaClass SFX as solution. Thanks to the principle behind the flip-flop screen machine, the screen panel moves like a trampoline. The bulk materials are accelerated to a high speed and can be screened easily. The additional stretching of the screen panel allows it to clean itself. Additional advantages of this innovation from Schenck Process are its low height, the low incline of its screen and the comprehensive monitoring and control options made possible by the use of variable-speed drives. The mounting of the screen without additional fixing elements creates a particularly large screen area, and the patented tongue and groove system allows for easy and rapid replacement of the screen panel. Transverse resonance beams and vibration elastomers can also be exchanged quickly. What’s more, the unit features full bulk material sealing thanks to its vibration elastomers and canvas cover.

//www.schenckprocess.com" target="_blank" >www.schenckprocess.com:www.schenckprocess.com