Schenck Process GmbH

AT: Give us a catchword that in your opinion best characterizes the SOLIDS 2015

Eric Jaschke: Innovation platform

AT: What are the novelties or products, respectively, you will present at the SOLIDS 2015?

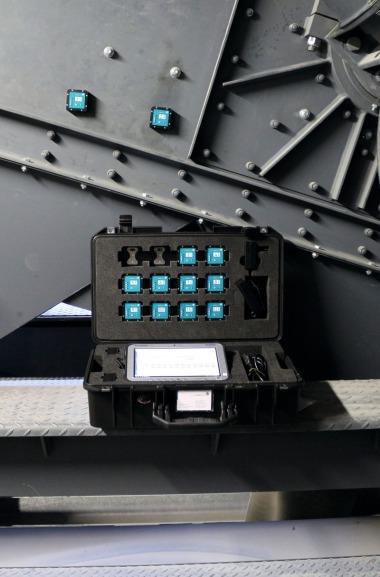

Eric Jaschke: In addition to our comprehensive portfolio of screening, weighing and feeding equipment for the bulk solids industry, this year the focus will be on CONiQ®, the Schenck Process condition monitoring system for screening machines and vibrating feeders. Due to the permanent measurement of the conditions and reporting of different parameters, such as temperature and mechanical vibration, CONiQ® protects the investments of our customers and, thus, enables a preventive maintenance.

AT: What is the special feature of the SOLIDS 2015?

Eric Jaschke: Positioning, prospects and potentials. For Schenck Process the 7th SOLIDS is a very valuable fair for customers of bulk handling to meet with us face to face. The SOLIDS 2015 is an ideal platform particularly for the German market to expand existing business relations, to get a market review of the future trends in the bulk solids industry and for exhibitors to position themselves as successful solutions providers to the process industry.

AT: How do you assess the future development of your business field?

Eric Jaschke: Schenck Process responds to the increasing requirements of its customers through precision, efficiency and process safety of its products and the continuous extension of its portfolio of intelligent and integrated components. The best example is the new generation of screens from Schenck Process, e.g. FlexaClass. The screens excited from the top classify even the most difficult to screen bulk solids. The service and after sales markets also are becoming more and more important. The trend is towards intelligent maintenance to help secure capital spending. With intelligent machine moniitoring systems such as CONiQ®, Schenck Process believes this trend will continue.

Hall 4 - Stand E 25