Optimized raw material removal

The voestalpine Stahl GmbH has awarded BT-Wolfgang Binder GmbH with a contract for realization of the project “Quarry logistics at Steyrling lime plant” by mid-2014. The scope of supply from BT-Wolfgang Binder comprises the entire handling and conveying equipment as well as the necessary structural steelwork such as conveyor bridges, screening facility, transfer towers, etc. and the installation. The contract is worth around 3 million €.

Andreas Mairwöger, Project Manager at voestalpine Stahl, explained that following the positive outcome of talks with the authorities in February 2012 and an intensive preparation phase of more than one year, the project Quarry Logistics Steyrling can now be implemented. “Start of work on the largest investment project ever realized in Steyrling was March 2012! One of the biggest challenges is that all work must be completed during regular operation, i.e. production blasting up to three times a week.”

Goal of the project is long-term assured extraction with the installation of new quarry logistics. The annual extraction rate at the Steyrling lime plant (Fig. 1) is around 1.2 million t. Since 1948, a total of 35 million t of rock have been quarried at the site. With four annular shaft kilns, burnt lime is produced for the steelworks in Linz, Donawitz and Kapfenberg. Steyrling thus covers almost 50 % of Austrian burnt lime production.

Steyrling lime plant has secured deposit reserves covering over 770 m based on an agreement with Baron Sydow. With the installation of the new quarry logistics, limestone extraction will be secured long-term for the next 80 years.

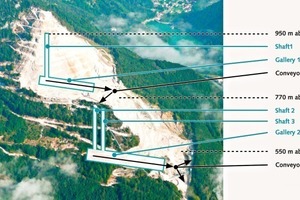

The extraction of the raw limestone will be switched from face extraction to sub-level benching with gravity shaft-gallery mining system. In addition, the changeover leads to a massive reduction in the dust emissions. Besides the construction of two galleries with a standard section of 20 m2 and 24 m2 and a length of around 330 m and 230 m and the sinking of three shafts with a diameter of 3.7 m and a depth of around 165 m each, conventional engineering work is necessary for installation of the conveying systems and the equipment required in the discharge chambers.

On a quarry plane of 970 m (Fig. 2) above sea level, a mobile diesel-electrically operated jaw crusher is being installed, with a tare weight of around 130 t at a crushing rate of 500 t/h. This machine is used for the limestone feed (particle sizes 0-1000 mm), sending the grain comminuted in a first stage (0- 250 mm) into a 165 m deep gravity shaft. The limestone is discharged from the gravity shaft by means of a heavy-duty chute, which transfers 500 t of rock per hour onto a belt conveyor with a belt width of 1000 mm. The center distance of this belt conveyor inside the gallery measures just below 400 m.

The limestone is transferred to the downstream conveyor outside the gallery. This belt conveyor transports the limestone onto a screen, which transfers the undersize (0-25 mm) into a second gravity shaft and the oversize (25-250 mm) via an 800 mm wide belt conveyor into the third parallel gravity shaft. Discharge from the second and third gravity shaft is done on heavy-duty chutes and two belt conveyors.

The center distance of the first belt conveyor measures 372 m and conveys 250 t of limestone per hour on a belt width of 800 mm. The belt conveyor that transports the material to the third gravity shaft has a belt width of 1000 mm and a center distance of 349 m, delivering around 400 t of rock per hour. These belt conveyors are designed as gallery belts, arranged on top of each other. The downstream belt conveyor connects to the existing installation, which is connected to the screening facility by a heavy-duty chute to be supplied.

Furthermore the stationary crusher will be moved and, in the scope of the conversion work, a heavy-duty conveyor grate, a 20 m3 intermediate bin and a new 1200 mm wide belt conveyor are to be installed. The total length of all belt conveyors measures around 1.15 km, including all equipment needed for instance for transfer towers and screening.

The electronic control of the entire project is set up in the kiln control room. Here the new conveyor routes are visualized and the new equipment designed such that it runs fully automatically. After commissioning of the new conveyor, the existing crusher on a level of 770 m above the sea level will be integrated in the new plant.