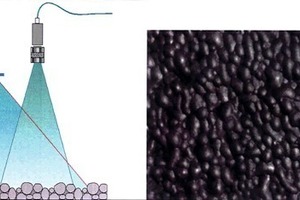

On demand control of reagent dosage for hard coal flotation

The beneficiation of the finest fraction is the most expensive process step in hard coal preparation. Herein the froth flotation is an integrated part which influences the operating costs in particular by the consumption of flotation reagent. Improvements of the control system of hard coal flotation could be reached by a reliable measurement of the feed’s solids content and by the application of an image analysis system for the froth of the last cell. A dynamic simulation model for the solids content of the feed circuit has been developed and implemented into the PLC system of the Auguste Victoria preparation plant. So expensive measuring equipment, in this case five radioactive density measuring devices, could be replaced by software. The control of the flotation process was greatly improved by a precise dosage of the flotation reagent without excess dosage for safety. At the same time that model opens the way for a successful application of the image analysis system for the flotation froth. Now an automatic subsequent adjustment of the reagent dosage to the raw slurry quality is possible. With a combination of the two measures a permanent reduction in reagent consumption of 15 to 30 % can be expected without losses of coal due to insufficient reagent dosage.

1. Introduction

The beneficiation of the finest fraction is the most expensive process step in hard coal preparation. Herein the froth flotation is an integrated part which influences the operating costs in particular by the consumption of flotation reagent. Dosage rates of 0.25–0.6 kg/t dry solids feed, dependent of the properties of the ROM coal, make a reduction potential of up to 30 % probable, if the dosage is appropriate. In addition, the repercussions of the flotation process on the following dewatering step, and so on the product quality, plays an important role if the dosage of oil is...