Coal tailings reprocessing and fines recovery

Summary: There are a large number of slurry ponds of coal tailings in countries like India. Not only these pose Environmental, Social and Governance (ESG) risks but also an opportunity to recycle and produce monetary gains. The tailings storage facilities (TSFs) can be accessed to retrieve coal slimes for further upgrading and dewatering. The management of tailings and reclamation of fines has to be done in an efficient and effective way. Coal slimes generated in the processing plants are usually sent to settling ponds for recovery of fines. The frequency of dredging settling ponds needs to be lessened and as well as stockpile drying time needs cutback. The use of effective processes of flotation and gravity separation are ideal for recovery. The process of recovery and proper reprocessing of the fine material should be undertaken to produce saleable product out of fine material. It will also help recycling reusable process water back to the wash plant.

1 Old king coal

Coal as an energy source has been known for its earliest application in heating homes in England in the early 17th century. Later on, in 18th century, the first industrial revolution was powered by steam engine invented by James Watt, coal being the driving force. It created an intense demand for coal. Steam locomotives became popular and found their presence worldwide. However, the good old king coal passed through twists and turns over the years. Coal, the primary source of electricity infrastructure, is growing its market presence at a steady space. All coals are not the same as there is a significant difference between metallurgical and thermal coals. From the angle of environmental pollution, both are treated as same.

Affordable energy is required for all levels of society including industrial and domestic consumption. The demand for energy is increasing in developing nations. In the western world, there are concerns about use of coal associated with greenhouse gas emissions and global warning. The developed economies are altering their attention away from coal mining. As coal is inexpensive to facilitate generation of electricity, India still considers coal as a major source of energy. Indian government is attracting mining firms from abroad to mine coal and reduce import of fossil fuels [1].

In the era of digitalization, the mining industry is not left behind. It is also making significant strides in integrating revolutionary changes taking place in the Industry. In spite of a surge in renewables, coal will continue to contribute to the global economy for a considerable time in the future.

2 Sustainable tailings management

The global mining industry has been producing a huge amount of waste and so is the Indian coal industry which ranks third in production worldwide. Coal Mining and Processing has left a trail of waste dump and tailings in slime ponds. This warrants development of processes for recovering value from rejects of yester years. In this paper, pros and cons of enrichment of tailings have been dealt with. The process of flotation has been examined through kinetics approach. A model flow scheme has been developed so that valuable material is recuperated efficiently.

The need for a comprehensive approach to coal tailings handling and processing leading to environmental, safety, and economic advantages, has become imperative. The volume of tailings can be reduced through recycling of coal waste. The tailings from the washing operations are thickened via gravity sedimentation and these thickened tailings are pumped to wet tailings storage facilities (TSFs). This does reduce the environmental and safety liability, but on the other hand, the economic viability needs to be considered. The relative cost efficiency of tailings management and disposal needs to be assessed to determine the viability of any project. The latest coal preparation technology can help realize more favourable outcomes.

3 Beneficiation techniques

There is currently an augmented importance on cleaning and coal recovery. The particular quality of Indian coal demands effective cleaning options. The most common types of coal cleaning processes can be categorized as either flotation separation or gravity separation. Beneficiation can meet the environmental pressure on disposal of raw coal tailings and further reduce the amount of solid waste disposal.

3.1 Flotation process

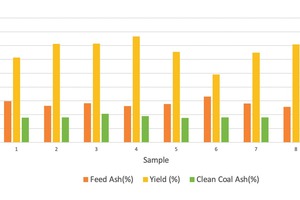

Flotation processes are quite different from gravity-based separation processes utilized for coarser fractions. The technology of flotation processes can be broadly divided into two types of devices: mechanical and pneumatic machines. Mechanically agitated flotation machines consist of cells in a row placed in tanks. The tanks are relatively shallow and rectangular, whereas column cells are usually tall vessels. Air is injected from a compressor into bottom of the column cell to keep the particles agitated. The absence of intense agitation promotes higher degree of selectivity. Modern flotation machines are high-intensive equipment designed to create very small air bubbles and higher flotation rates. Four to eight cells are usually employed for the traditional mechanical circuit. Re-cleaning of the concentrate or scavenging of the tailings may not be necessary. The results of flotation tests are shown in Fig. 1. Column flotation should be used if there is clay as it gets entrained in the froth [2].

((Bitte hier Bild 1 einfügen))

3.1.1 Flotation kinetics

The rate constant (k), retention time (τ), and cell mixing – Péclet number (Pe) determine the performance of flotation process. While Pe tends to ∞, it becomes a plug flow system leading to maximum recovery of concentrate contrary to a well-mixed system. Thus, cell mixing plays an important role in the areas affecting flotation.

The time required by a coal particle to stay in the pulp for optimum recovery is called retention time. It takes 3.5 to 4 minutes of residence in a coal flotation circuit. Accordingly, the number and size of the flotation cells should be adapted to have the requisite amount of time for flotation.

Mean retention time can be ascertained by using retention time distribution (RTD) testing or by using the formula:

((Hier bitte Gleichung 1 einsetzen))

Where, V is the active volume of the cell and Q is the flow rate to the cell. RTD testing comprises of using a tracer solution, such as salt, applied to the feed end of a flotation cell and taking timed samples vs. concentration of each sample at the tails of the cell.

The rate constant (k) indicates how fast coal floats and is dependent on various dynamics.

3.1.1.1 Flotation kinetics in perfectly mixed cells – effect of collection zone

Despite being a complex process, flotation can often be modeled using simple kinetic expressions.

For a system exhibiting perfect mixing, the equation becomes:

((Hier bitte Gleichung 2 einsetzen))

where R is the factional recovery, k is the rate constant [1/min] and τ is the mean retention time [min].

((Hier bitte Gleichung 3 einsetzen))

A simple calculation shows that the total recovery (RN) for n tanks in series is:

RN = Ri + Ri (1 – Ri) + Ri (1 – Ri)2 + Ri (1 – Ri)3 + ⋯ + Ri (1 – Ri)N = 1 – (1 – Ri)N

((Hier bitte Gleichung 4 einsetzen))

3.1.1.2 Flotation kinetics in a plug flow system – effect of froth zone

The flotation rate is equal to the rate of change of concentration of floatable material in the cell

((Hier bitte Gleichung 5 einsetzen))

This is the basic rate equation, in which the value of n denotes the order of the equation and k is the flotation rate constant.

First order rate equation with n = 1, gives:

C = C0e–kt

Where C0 = the concentration of valuable material in the cell at zero time, and C = the concentration of valuable material remaining in the cell at time t.

Taking the logs of the above equation:

((Hier bitte Gleichung 6 einsetzen))

If the experimental values of ln (C0/C) are plotted against t, the graph should be a straight line of slope k if n = 1. The higher the value of rate constant, higher is the collecting power of the reagent used, which provides a means for comparison between different reagents in flotation of a particular mineral.

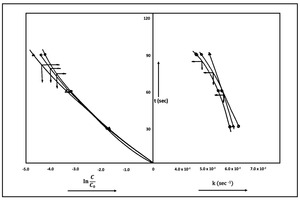

Using the above equation, the flotation process can be studied from the kinetic point of view. The values of k and C/C0 are plotted against time t in Fig. 2. The curves are more or less linear, so they correspond to first order equation. The rate constant is also an important guide to study the different parameters of the flotation process.

((Bitte hier Bild 2 einfügen))

Commercially available pneumatic cells include HydroFloat, StackCell, and Pneuflot amongst others.

3.2 Gravity based separation

The surface-based flotation process may not be favourable for all types of coal fines. The enhanced gravity separators (EGSs) can do efficient upgrading of ultrafine particles down to below 38 μm for most coals. The separation efficiency falls as the fine particle size decreases. This low performance can be improved by increasing the settling rate of fine particles by using centrifugal acceleration instead of gravitational acceleration. This has led to the development of a new generation of enhanced gravity (centrifugal) separators. This includes the commercially available units – Falcon concentrator, Kelsey jog, InLine pressure jig, Knelson concentrator, and multigravity separator [3].

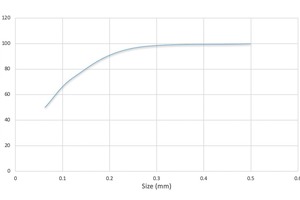

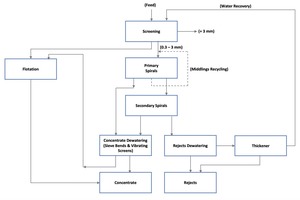

As the focus here is limited to reclamation of slime ponds, it does not call for wide discussion on different equipment related to gravity-based processing. Therefore, the choices evaluated are confined to spirals and reflux classifier only. Size distribution of the feed (Fig. 3) is important and should be controlled for efficient operation.

((Bitte hier Bild 3 einfügen))

3.2.1 Spirals

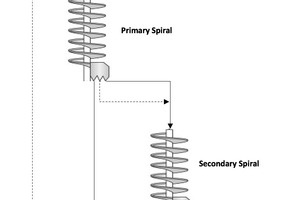

Spirals are very popular amongst the fine coal-cleaning technologies due to low capital cost, ease of operation, and other advantages. Compound rougher – cleaner spirals with middlings recycling give better separation performance (Fig. 4). Typical separating relative density (RD) is well above 1.55, which can be improved by increasing the number of turns around the vertical shaft by adding three additional turns to a seven-turn, two-stage spiral, making a ten-turn spiral [4]. Low-density separation is attractive in fine coal recovery for metallurgical coal producers worldwide. The new spiral has shown higher recoveries even for minus 1 mm fractions. It can serve as an alternative to jigs in the minus 3 to plus 1 mm size range. It is cost effective as spirals use no electricity, and are also easy to maintain. Latest spirals available in the market are Mineral Technologies’ LC3 and Multotec’s SX10 [2].

((Bitte hier Bild 4 einfügen))

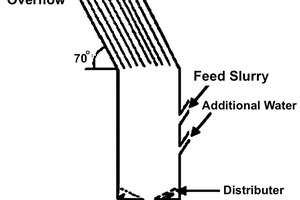

3.2.2 Reflux classifier

Reflux Classifier (RC) units are state-of–the–art fine particle technology and are ideally suited for separation of coal (typically < 2.0 mm). A RC has the dual advantages of gravity-based separation and particle size classification. Low density particles are sorted upward as overflow due to the turbulent motion created by the fluidization water injected from below while the high-density particles sink to the bottom as underflow (Fig. 5).

((Bitte hier Bild 5 einfügen))

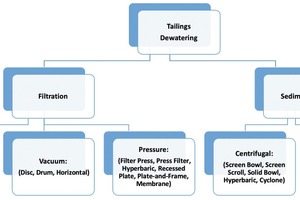

4 Dewatering technology

It is necessary to evaluate the numerous variables impacting dewatering technology in order to arrive at a sustainable and economic decision in a changing scenario. Individual equipment and components need to be studied while selecting the most appropriate fine tailings dewatering

The different techniques of dewatering fine coal are illustrated in Fig. 6. Out of the different dewatering techniques, the centrifuge offers the highest amount of water removal. Screen bowl centrifuge is widely used for fine coal dewatering due to its relative low cost as well as ease of operation and maintenance. It removes more ultrafine clays and can also control the moisture content of concentrate.

((Bitte hier Bild 6 einfügen))

Belt filter press technology is also considered as a viable solution for a comprehensive range of process conditions such as continuous operation, relatively low capital and operating costs, high mechanical reliability, and equipment availability.

Deep cone paste thickeners are designed to maintain a deep bed of settled solids and maximize gravity compression. This type of thickeners produces underflow solids with the highest solids concentration with a paste consistency transportable by pumps. It is less voluminous, less costly and easier to install compared to standard thickener. Thickeners are the foundation of the tailings management process. Thickeners can also be followed by filter presses, completely eliminating ponds and impoundment structures [3].

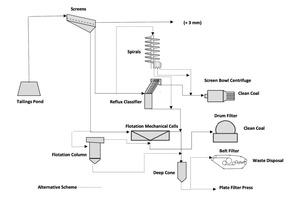

5 Reclamation of TSF

Slurry ponds represent a source of relatively cheap energy if the calorific value of slurries is high enough or can be upgraded by proven technology and equipment. A large-scale program of sampling and testing is required to be undertaken in designing the beneficiation plant. On the other hand, there are several Environmental, Social & Governance (ESG) risks associated with slurry ponds. They pose a danger to the environment from coal dusts during longer dry periods, spontaneous ignition and contaminating groundwater. In the case where the ash content is relatively low, it is common practice to reclaim the slurries, and expose them to the atmosphere for reduction of moisture so that they can be used for heating or power generation.

In the case of coking coal washing, the coal fines are normally enriched with virtrinite, which is an important component responsible for increasing the coking propensity of the total cleans. In regular operation, increasing amount of fines along with non-functioning flotation plants have resulted in disposal of fines in ponds. As the aggregate of fines collected and stocked amount to a huge quantity, the recovery of slurry from the ponds becomes an attractive proposition. Fines (tailings) tend to have a higher calorific value than coarse wastes. The preparation plant designed for slurry reclamation can be a mobile unit to cater to the needs of slurry ponds scattered over the mining regions. A stationary plant may not be justified due to the limited quantity of slurry in the respective ponds. Therefore, a mobile plant is more justified. The beneficiation process can produce good-quality low-cost fuel from the material that was formerly regarded as waste. The reclamation of pond material is an active contribution to mitigation of environmental hazards and at the same time the former pond sites may be rehabilitated. This will help mitigate some of the ESG risks associated with TSFs. Currently, small plants are in place to recover these slurries, and are run by private standalone operators.

Suitable Flow Schemes are indicated in Fig. 7 and Fig. 8.

((Bitte hier Bild 7 einfügen))

((Bitte hier Bild 8 einfügen))

6 Economic viability of reclamation

The performance of beneficiation process for a two product operation can be elaborated by the following:

The fraction of a certain material contained in the feed represented in percentage is called recovery (R). This can be expressed in terms of assay value of feed, concentrate, and tailings. The recovery may be presented as:

R = (Rc + Rt) = 100 ……. (1)

Rc = 100*Cc/Ff ……….... (2)

Rt = 100*Tt/Ff …………. (3)

Ff = Cc + Tt ……………. (4)

Where,

Rc = Recovery percentage of concentrate

Rt = Recovery percentage of tailings

F = Weight of the feed

C = Wight of the concentrate

T = Weight of the tailings

f = Fraction of the material present in the feed

c = Fraction of the material present in the concentrate

t = Fraction of the material present in the tailings

The goal is to maximize net profit: NP = (value of concentrate – mining cost – processing cost). There is no mining cost just because the material was already extracted and dumped. The values of c and t are therefore to be imposed; the amount of Rc and of Rt must be determined in order to maximize the net profit NP = (value of concentrate – processing cost + value of final tailings), according to the equation (5):

NP = RcP – F * Cop + RtVt ……. (5)

Where,

P = Selling price per tonne of concentrate ($/t)

Cop = unit mineral processing cost ($/t)

Vt = unit value of tailings ($/t)

Different schemes are to be worked out to arrive at a suitable techno-economic solution.

7 Concluding remarks

There are a number of coal preparation plants operating in India. There is an intrinsic problem – flotation units are not functioning, some of them are not working at all. The coal slimes are diverted to slime ponds. In case of coking coal, increased concentration of vitrinite in ultrafine fines leads to enhanced coking properties, which may find market for coke making. Thus, there is scope of recovery of this valuable residue. It is necessary to evaluate and invest in more efficient and cost-effective systems to separate and concentrate the waste materials. The dewatering process creates nearly dry solids while recovering additional water from the waste stream.

The tailings management procedures are required to be enhanced due to stringent environmental restrictions, limited operational space availability, higher operational and handling costs, reduction of water consumption, and safety requirements [5]. The recycling application opens up options for urban mining by recovering valuable coal from rejected wastes.

As they say, prevention is better than cure, all efforts should be directed to make the slime ponds redundant and manage ESG risks.

Literatur • Literature

[1] Kumar, D. and Kumar, D.: Management of Coking Coal Resources, in: Elsevier Inc. (Publisher), Waltham, MA/USA, 2016

[2] Fiscor, S.: Low-Density Separation Techniques Recover Valuable Coal from Fines, Coal Age (2021), March, pp. 22-24

[3] Kumar, D. and Kumar, D.: Sustainable Management of Coal Preparation, in: Elsevier Inc. (Publisher), Cambridge, MA/USA, 2018

[4] Arnold, B. J. et al., 2019, Development of a low specific gravity cut-point spiral, Proceedings of XIX International Coal Preparation Congress, Vol. I, 13 to 15 November, New Delhi, India, Woodhead Publishing India, 2020, pp. 370-377

[5] Zink, D.: Step Up to The Plate Filter Press, World Coal (2021), Issue 1, pp. 41-44

Authors:

Dr. mont. Dilip Kumar, MScA (Mons), Scientist

Dilip.KUMAR@alumni.umons.ac.be

Dilip Kumar is an expert on coal preparation and has published widely. He is a retired chief mining scientist of Central Mine Planning and Design Institute (CMPDI), Ranchi/India. He is engaged in consultancy and technical writing, currently based in Vancouver/Canada.

Deepak Kumar, BSc, MBA

Deepak Kumar holds bachelor’s degree in software engineering as well as MBA from the University of British Columbia, Vancouver/Canada. He is a portfolio manager and a management consultant. He has worked professionally in North America and Western Europe. At present, he is engaged with Central 1 Credit Union, Canada, where he is evaluating capital and technology investments in projects, shaping corporate strategy, and executing on initiatives to optimize operations.