New website specifically for the diamond industry

Easy-to-navigate information

1 The new diamond microsite of TOMRA Sorting Mining provides an overview of diamond mining offerings and solutions

1 The new diamond microsite of TOMRA Sorting Mining provides an overview of diamond mining offerings and solutions

© TOMRA Sorting Mining

Navigation of the diamond microsite is intuitive and the detailed information is presented in a clear and easy-to-understand format. “We developed it based on the questions our customers ask during our meetings,” explains Ryan Szabo.

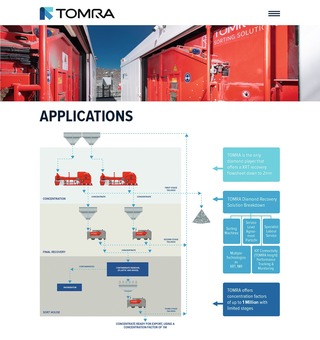

The microsite’s Homepage opens with a clear statement of TOMRA’s promise to diamond producers: 100 % detection in the specified range, irrespective of luminescence profile or coating, and a guaranteed diamond recovery greater than 99 %. Scrolling down, viewers can see at a glance the stages of the process where TOMRA sorters can add value: Concentration with its XRT sorters and Pre-concentration with its Color and Near Infrared (NIR) solutions – and they will discover that a solution for Final Recovery will soon be available. This will be an industry first: XRT recovery technology down to the size of a 2 mm rough diamond, which will deliver concentration factors up to 1 Million with a much-reduced number of concentration stages.

Process flowsheets and process flow diagrams

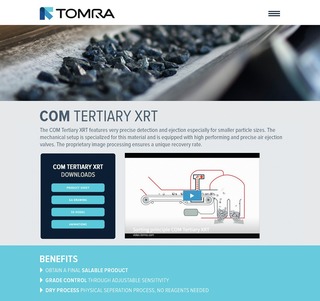

2 The product page provides detailed technical information – product sheets, General Arrangement drawings and 3D CAD drawings

2 The product page provides detailed technical information – product sheets, General Arrangement drawings and 3D CAD drawings

© TOMRA Sorting Mining

In the Applications section of the microsite, a flowsheet shows where the different TOMRA machines fit in the recovery process and how they add value. Further detail is provided in animations of process flow diagrams in Kimberlite, Alluvial batch fed and Alluvial continuous feed applications.

“With these flowsheets we want to help our customers to navigate and understand where the equipment goes," adds Ryan Szabo. “We show the locations where the sorters fit within different types of operations. This will give the customers an understanding of how the process can be simplified and the number of stages that can be replaced by the TOMRA sorters.”

Detailed product information, service details and

digital offers

The product page provides detailed technical information – product sheets, General Arrangement drawings and 3D CAD drawings. Customers can even download a 3D model and place it in their plant’s 3D drawings to see exactly how it would fit, what it would change in their set-up and how.

Details of TOMRA’s Service Level Agreements are also on the microsite. Unique on the market, these plans offer tailored solutions to match client requirements and protect their investment. The Service section includes information about TOMRA Insight, the cloud-based solution that turns the customer’s sorters into connected devices and provides secure, real-time monitoring.

Customers considering the integration of TOMRA’s solutions in their operation can also find information about existing installations. They can hear from diamond producers about their experience with TOMRA and learn about the potential benefits in an interview with Geoffrey Madderson, Diamond Segment Manager for TOMRA Sorting Mining. They can also view photographs of remarkable diamond recoveries and existing installations such as the one at Karowe mine in Botswana, where record-breaking diamonds have been recovered with TOMRA’s XRT technology.