Lower maintenance requirement – more efficient conveying

Application in three-shift operation, extreme forces, and

harsh weather conditions, with constant use under heavy loads demands a great deal from conveyor systems. The components for the belt conveyors supplied by Schulte Strathaus are therefore designed to protect the conveyor belts, maximizing their maintenance-free service lifetime. The combination of resistant materials and sturdy design makes the components particularly rugged, substantially reducing wear. At the same time, the components make a crucial contribution to the conservation of resources. The scrapers, for example, ensure optimum cleaning of the belt conveyor, removing any material sticking to the belt. The scrapings fall into the transfer area and do not have to be manually removed from underneath the conveyor. The scraper systems and other components for belt conveyors from Schulte Strathaus will be on show at this year’s “Schüttgut” trade fair. The different products are available in various models, which can be combined in line with the individual requirements of the final operator. To achieve optimum cleaning of the belt conveyor, Starclean scrapers are used. The wear parts of the scraper can be quickly replaced without tools thanks to a simple but secure snap-in mechanism.

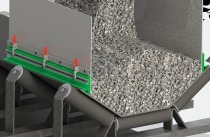

For protection against damage by large, angular material fractions or as a result of large dropping heights at transfer points, Friflo impact bars are designed by Schulte Strathaus to absorb the drop energy of the bulk solids. For this purpose, the conveyor belt is supported in the transfer zones with impact bars with rubber dampers. Their surface is coated with a covering of special gliding HDPE with a very low friction coefficient of < 0.1.

For an especially low-dust material feed, in addition to the impact bars, Spillex transfer point seals are also used to reliably seal the transfer points and ensure low-dust and low-loss material transfer. Unlike conventional seals, the Schulte Strathaus system does not use any end-to-end rubber strips, but individual segments. The individual segments fit optimally to the belt. In the case of uneven wear, each segment can be individually adjusted and re-fitted to the conveyor belt. The special rubber mix ensures that the belt is protected and wear reduced.

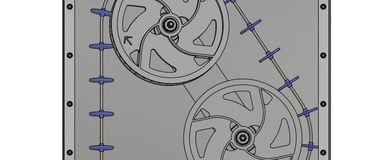

Enclosed belt conveyors complete the range offered by Schulte Strathaus. These are able to safely negotiate even the narrowest radii – both horizontally and vertically. At the same time the enclosed system prevents dust generation and protects the conveyed material from the elements.

Hall 4; Stand G 15