Lafarge Aggregates orders for Mogensen

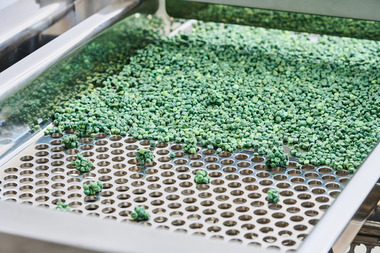

In the autumn of 2012 Mogensen received an order from Lafarge’s Mountsorrel Quarry in Leicestershire for a large vibratory spreader feeder Type F5408CT (Fig.) designed to separate a single feed, brought into the screen house by a 1200 mm-wide belt conveyor, into two equal streams and spread those flows evenly across the whole width of each of two existing 2 m wide Hein, Lehmann Liwell® “Flip-Flow” screens. The Mogensen feeder was delivered early in December 2012 and replaces a “trouser-leg chute” arrangement, which had proved to be unsatisfactory. The aim of the new equipment is to improve the screening efficiency and capacity of the Liwell machines by making use of the whole of their screening area. The installation was commissioned in mid-January and is working as planned, fully facilitating the hoped-for improvements in screening efficiency. The feed to the whole plant is currently 500 t/h of -8 mm Leicestershire granite with a moisture content varying up to 20 %.

The spreader feeder is equipped with replaceable 6 mm stainless steel protection to the feed plate area and 3 mm stainless steel to the inlet and outlet chutes. It is powered by two counter-rotating Invicta rotary electric vibrators Type BLz 45-50/6 each delivering 5000 kg (49 050 N.) of centrifugal force. Mogensen has been a supplier of vibratory sizing and heavy-duty feeding equipment to Lafarge Aggregates (UK) Limited and its predecessor companies such as Redland Aggregates, not only at Mountsorrel but elsewhere in the group, for over forty years. Early in January the company also delivered a 2-m, 5-deck Mogensen Sizer to Lafarge’s Dry Rigg Quarry in Upper Ribblesdale, where it will be included in a rebuild of the screen house.