Keep screening – even under most aggressive conditions

Inelas Poliuretanos, S.L. is a Spanish company that has been manufacturing polyurethane elastomers since 1966. It is specialized in optimizing and solving problems that commonly arise in certain specific mining processes, such as screening, transportation of abrasive solids via pipeline, flotation, and abrasion erosion at certain stages, advising clients on the implementation of innovative, simple and high-quality polyurethane products to improve performance and profitability during these processes. It is difficult to dry screen the smallest aggregates when these are clay materials with a high moisture content or at very low ambient temperatures. “Special” screens and other “screen cleaning systems” are marketed as “anti-silting” devices. While they can work well with low humidity or under minimally aggressive screening conditions, they cease to be effective as the moisture content of the material increases, until they finally become plugged like any other type of screen.

To solve this problem Inelas Poliuretanos, S. L. observed a dry screening process. It became evident that it was a matter of time (sometimes just a few minutes) before the holes became plugged. It was also clear that a screen that is struck does not become plugged at the point where it periodically receives an impact (Fig. 1). This principle applicated to the entire screen, helps keeping it permanently clean. Based on these premises, the company manufactured a simple device that could strike the entire screen without damaging it, at intervals short enough to prevent the accumulation of aggregate, to ensure that the holes are always open. This system has already been implemented and tested in many aggregate plants, as well as on screeners at some of the largest mines and aggregate and mineral processing and grading plants in the world. There is clear evidence of the benefits and profitability of this system in mines, quarries and gravel pits that have this type of problem.

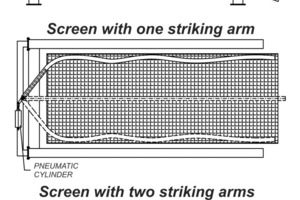

Depending on the width and characteristics of the screener, the device consists of one or two flexible moving polyurethane arms with a length adapted to the screener (Fig. 2). At adjustable time intervals, the arms sweep across the entire surface of the screener with an angular reciprocating movement between the screener’s walls. The vibration of the screener causes a snaking movement in each arm with a jolting effect that causes it to strike the screen, preventing plugging. A two-way pneumatic cylinder transmits the movement to the flexible arm(s). The movement then becomes angular by means of an intermediate axle. A control cabinet houses the pneumatic components for controlling the speed of the movement of the striking arms as they sweep across the screen.

Tests have been carried out over the course of eight months at the “La Closa” plant owned by Arenes Bellpuig, S. L. in Lleida/Spain (Fig. 3). A TUSA HN-170 screener was used, measuring 2400 x 7200 mm and capable of processing 350 t/h. The type of aggregate screened is primarily limestone with a certain amount of siliceous content. Its high clay fine content, between 10 and 40 %, combined with a moisture content between 3 and 12 %, make screening a very arduous task.

The feed is quarry run, around 0/120 mm in size, with a content 0/4 mm in size constituting between 30 and 40 %; this represents 100-120 t/h. The 0/4 mm material is separated in the Tusa HN-170 screener by dry screening. In a subsequent operation, it is washed to eliminate clay fine and is then used as sand for precast concrete products. Larger sized materials are ground and screened to produce different standard sizes of gravel: 4-12, 12-20 and 20-40 mm.

Before installing the pneumatic screen cleaning system, the top screening deck has been equipped with protective screens made from double corrugated steel with 13 mm openings for trouble-free performance. To obtain the 0-4 mm material in this screener, tests were carried out with all types of “screen cleaning systems” and “anti-silting” screens. The minimum permitted mesh opening is 8 x 8 mm. Any type of screen with an opening smaller than 8 x 8 mm becomes plugged in a matter of minutes. Grading and washing at 0/4 mm is then required. After washing, the excess ungraded 4/8 mm material cannot be sent to the mill, as its high moisture content would cause it to clog the grinding chamber. Nor can it be sold, since it is pebble aggregate that is unsuitable for the manufacture of concrete. Its final destination is a landfill.

Under optimal conditions, dry aggregate was able to be processed at a rate of 350 t/h. When the incoming aggregate had a moisture content of 5 %, rates dropped to 200 t/h, and it was necessary to stop for manual cleaning up to five times every eight hours. This manual cleaning involved stopping production so that an operator could enter the screener to remove the aggregate stuck in the screen by striking it with a hammer. With an aggregate with a 7 % moisture content, rates either slowed to 100-120 t/h or the decision was made to stop production.

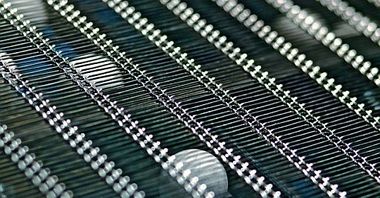

In order to test the pneumatic screen cleaning striking arm system two striking arms were attached, due to the width of the screener. The already existing protective screens were kept on the top screening deck (made of double corrugated steel with 13 x 13 mm mesh openings), as this deck was working without any problems. High-performance INE‑FLOW® screens made of INAPRENE® polyurethane and with 7 x 7 mm square mesh openings were installed on the bottom screening deck. When it became evident that these screens were not the least bit plugged, the size was reduced at the request of the company. Currently, two screens with 5 x 5 mm openings and three screens with 4 x 4 mm openings are used, ensuring that the mesh openings are always open. It has even been possible to grade this type of aggregate, considered difficult to screen with a conventional screener, using screens with 4 x 4 mm mesh openings.

In eight months, it has not been necessary to clean the screens at any time. The striking arms prevent plugging by cleaning the entire surface of the screener at sweeping intervals of approximately 2 minutes (Fig. 4). This is very important where workplace safety is concerned, as it completely eliminates the risk of having to clean the inclined, often slippery screens while obeying stringent safety regulations. Production capacity has been increased to maximum possible levels on this screener. This has also resulted in energy savings and reduced down time by eliminating the need to stop and start the screener for cleaning. The use of elastic materials on the screens and striking arms contributes to an improved working environment, as the noise level is considerably reduced.

Arenes Bellpuig, S. L., had also an important added financial benefit, as it was previously only possible to screen with a minimum mesh opening of 8 x 8 mm. The 4/8 mm material that used to be washed and then disposed of is now combined with the 8/12 mm material from the first dry screening, processed and sold, resulting in a considerable increase in production and lower costs. Since there is no waste produced, the environmental impact is also improved.

The application of the striking arms make it also possible to use even smaller screening sizes, as demonstrated in other grading plants. The INE-FLOW® screen line of Inelas Poliuretanos, S. L. includes square openings as small as 2 x 2 mm, while still maintaining the same screening surface as spring steel or conventional screens. At least Inelas Poliuretanos, S. L. has developed a practical and environmentally-friendly system that can be adapted to any “conventional” screener. It is an ideal complement that provides an effective solution at a very low actual cost, providing excellent results.