Intelligent agglomeration technology for recycling steel mill residues

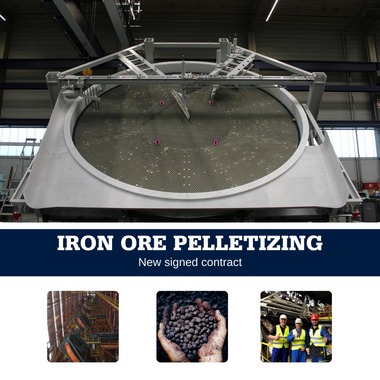

1 Pelletizing disc HAVER SCARABAEUS®

1 Pelletizing disc HAVER SCARABAEUS®

© HAVER NIAGARA

As an example of the use of the pelletizing disc HAVER SCARABAEUS® in the recycling of steelworks remnants, such as blast furnace dust and sludge, converter dust and sludge, electric arc furnace dust, metallurgical debris, mill scale, mill scale sludge and various slags will be focused in the following. Since these metallurgical waste materials contain impurities such as zinc and lead, the reuse of these residual materials in the blast furnace or direct reduction plant may be problematic. Some of these materials are landfilled, anyhow the very most proportion is recycled to zinc, nickel, molybdenum or chromium.

Worldwide approximately 6.75 million t of electrical arc furnace dust are produced annually. These dusts contain 1.6 million t/a of zinc. In the past these dusts and sludges had been landfilled. Since several decades different extraction processes for special reasons are in industrial use and only little amounts of the remains were discarded as dumps. About 35 Waelz kilns with an average capacity of 75 000 t/a are installed worldwide. They process every year 3.4 million t of electric arc furnace dust [1].

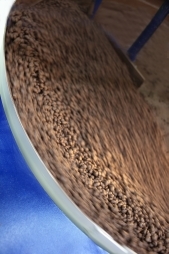

2 Prior to the Waelz process, the zinc-containing components dust and sludge, coal and lime are homogenized and pelletized

2 Prior to the Waelz process, the zinc-containing components dust and sludge, coal and lime are homogenized and pelletized

© HAVER NIAGARA

Most recycling-processes are faced with very small particle sizes of the steel work remnants. Thus agglomeration is necessary in order to improve transport, storage and utilisation properties, especially the reintroduce into the metallurgical process. The pelletizing disc HAVER SCARABAEUS® is perfectly suitable and in multiple use for the transmission of fine-grained particles into larger agglomerates with defined particle size distribution and smooth surface [2].

In zinc recycling, zinc-containing residues are reduced by carbon carriers in rotary kilns. Zinc and lead sublimate and are re-oxidized in the air flow in counterflow and are transported and separated in downstream waste gas purification plants. In the production of Waelz oxide, lime is used for slag formation. Prior to the Waelz process, the zinc-containing components dust and sludge (approx. 74 wt. %), coal (approx. 19 wt. %) and lime (approx. 7 wt. %) are homogenized and pelletized. In opposite to the dust, the pellets have got improved transport and storage properties and most important significantly enhanced utilisation properties.

As the Waelz kiln works in counterflow, the risk of discharging unprocessed materials and contamination of the product is high. Defined particle sizes of the steelworks remnants pellets are a pre-requisite for Waelz kiln optimization. Typically the pellets have a moisture content of approx. 14 wt. %. The target size of the pellets is mostly approx. 4 – 8 mm. The capacity of the HAVER SCARABAEUS® in the recycling sector is approx. 50 000 – 150 000 t/a.

As early as 2010 HAVER ENGINEERING GmbH developed a pelletizing prozess, which was adapted to the individual requirements of the Waelz kiln process [4]. One year later HAVER NIAGARA GmbH delivered a HAVER SCARABAEUS® 4200 for this process optimizing project in Germany. The plant was running with a vertical intensive mixer to blend the feed materials and charge them directly into the rotary kiln. To optimize the kiln capacity and the Waelz oxide output, the customer decided to produce agglomerates in the SCARABAEUS® (better reaction with the process gas in the kiln due to higher permeability of the pellets). It was possible to increase the zinc output significant using the combination of a mixer and a pelletizing disc with a capacity of approx. 17 t/h instead of only using the vertical intensive mixer as they done before.

The target of the project was to increase the total throughput and optimize the zinc recovery. Due to the pellet production the customer could not only achive the set targets they exceed them.

The basic idea of the customer was using an agglomerate with high porosity to have a fast gas diffusion through the agglomerates into the inner core. Comparing the nature of agglomerates generated in a mixer and in a disc a general difference is the density of the agglomerates. Usually pellets produced in a mixing process have a higher density due to relative high energy input into the material by the agitators and a more coarse particle size distribuion compared to the roll agglomeration in a SCARABAEUS® which is characterized by its segregation effect.

The process chamber of the SCARABAEUS® is made by an inclined, rotating, flat cylindrical pan. Due to rotation of the pan, the fine material is pulled along to the disc uppermost point and then rolling down onto a material bed. Caused by the special movement of the material itself and the addition of water onto the material, nucleation and growing occurs as a result of the settings of the pelletizing disc. Typically, final pellets with a very tight particle size distribution are discharged continuously over the board of the SCARABAEUS®.

Due to the good porosity of the pellets and the tight particle size distribution what leads to a high pellet bed/bulk permeabilty the capacity of the kiln and the zinc recovery increase.

In the following years that process was adapted on similar or comparable processes. Pelletizing discs with diameters from 2.2 – 5.2 m are to be found nowadays in recycling of steelworks remnants.

HAVER & BOECKER NIAGARA supports the customers to develop and optimize their processes, machines and plants. In the test facility various equipment of pelletizing is used to determine material and process data in order to create a mature engineering, which meets customer technical requirements and economic benefits.

Literatur • Literature

[1] Noël Masson, Pascal Briol, PBSIM & BFS Consulting Engineering; Zinc One Resources Inc.: A Brief Summary of Zinc Oxide Processing Methods Available for the Bongará Deposit. 2017

[2] Eberhard Gock et al; Verwertung von deponierten eisenreichen Filterstäuben der Stahlindustrie durch Pelletierung. Recycling und Rohstoffe. 2013

[3] Eckhard von Billerbeck et al; Verarbeitung von Filterstäuben aus der Elektrostahlerzeugung im Wälzprozess. Mineralische Nebenprodukte und Abfälle. 2014

[4] Jan Lampke et al; Solid and compact. AT MINERAL PROCESSING 03/2011, pp.54-61