Iron ore & pelletizing technology

All modern methods of energy generation and transmitting consist of iron and steel. Thus, we cannot renounce iron ore mineral processing, even though iron and steelmaking sector is one of the largest energy consumers in the world. It is our duty to improve the iron ore beneficiation in order to implement sustainable solutions to minimize CO2 emissions and to improve resource efficiency by better process and product performance.

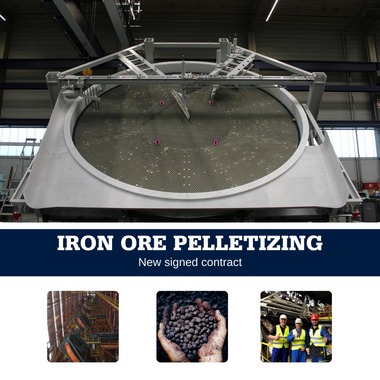

SCARABAEUS pelletizing discs provided by HAVER & BOECKER NIAGARA are used for sustainable and efficient production of iron ore pellets. The unit’s design minimizes circulation, increases productivity and profitability. The pelletizing discs used for agglomerating iron ore concentrates into pellets are remarkable for their very narrow particle size distribution with a target size of 10 – 14 mm, important for DR-processes.

The powder-type feed material is formed into pellets with use of water as the liquid binding agent. The optimum operating parameters can be set by changing the inclination, the rotational speed, mass flow rate, and now also the rim height thanks to the innovative automatic pelletizing disc control system. The integrated camera ensures continuous monitoring of the quality of the pellets. In order to develop the best solutions for customers and to determine which process is the best for their iron ore and pellets requirements HAVER & BOECKER NIAGARA are conducting iron ore pelletizing tests in the Associated-Institute of TU BERGAKADEMIE Freiberg – HAVER ENGINEERING GmbH.

The SCARABAEUS process generates higher tonnages by minimizing the material return rates and avoids double processing of over- and undersized pellets due to automatic machine parameter adjustments, which can also adapt to varying material property fluctuations in the feed material. The SCARABAEUS process creates pellets so high in quality that they can be utilized for the direct reduction process. This in return can create enormous CO2 emission savings, thus minimizing the mine’s impact on the environment.

Pelletizing – why?

The undiminished demand of iron ore leads to mining of even lower-valued deposits. The reduced quality of the natural resources stands in opposition to the economic, ecological and technological restrictions, which require an intensive mineral processing of the iron ore. An enrichment of iron components is achieved by separation of undesirable components.

However, for this it is necessary to crush the ore to the decomposition grain size and to supply sorting processes such as magnetic separation and flotation. To improve the process and product properties of the fine-grained iron ore concentrates, it is necessary to agglomerate these concentrates. Pelletizing of iron ore concentrates in pelletizing discs leads to narrow grain size distributed pellets with smooth surface.

Pelletizing – how?

The process chamber of a pelletizing disc is made by an inclined, rotating, flat cylindrical pan. Due to rotation of the pan, the fine material is pulled along to the disc uppermost point and then rolling down onto a material bed. Caused by the special movement of the material itself and the addition of water onto the material, nucleation and growing occurs as a result of the settings of the pelletizing disc. Typically, final pellets with a very tight particle size distribution are discharged continuously over the board of the SCARABAEUS® 7500.