Installation-friendly mounted bearings for demanding applications

With its SNN series, NSK is presenting a new series of plummer blocks that have been developed for use in unfavourable application conditions. Various types of roller bearings and sealing materials are available to ensure the optimum adjustment of the easy-to-install bearings for any application.

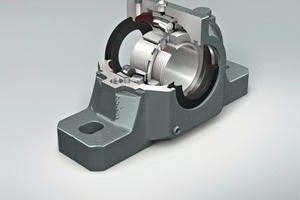

Plummer blocks are often used in applications involving adverse conditions, e.g. in conveyor systems, in equipment in the quarrying industry, in fans and compressors as well as in steel production and processing. The new plummer blocks in the SNN series (Fig.) were designed precisely for such demanding applications. They are exceptionally easy to install thanks to design details, such as the solid corners of the housing that provide an optimal hold for positioning pins, and a centre mark for easy alignment.

A high-quality casting with high rigidity is used as the housing. The FEM-optimised design enables a reduction in weight and very good heat dissipation. Moreover, the precision-engineered split housing ensures easy replacement of the bearings. Relubrication is possible via two boreholes. A grease drain hole is also provided. The housings can be fitted with quality self-aligning ball bearings or spherical roller bearings from the NSK range, which achieve a very long lifetime even when exposed to high loads. They reliably compensate for misalignments and increase the lifetime of the entire drive.

A central design element for plummer blocks in adverse environmental conditions is the sealing system. With the SNN series, the user has the choice between double lip seals, V-ring seals, felt seals, labyrinth seals and taconite seals, and can therefore select the optimum seal for the individual application depending on, for example, the surrounding temperature, shaft speed and the type of the contamination. The mounted units in the SNN series can be supplied for shaft diameters from 20 mm to 140 mm. For larger shaft diameters up to 380 mm, the new SD 3100 series is available.