Significantly longer service life for conveyor bearings

For reasons of cost and simplified installation, plummer block housings with open spherical roller bearings are usually installed in the tension rollers of conveyor systems in mining and quarries. The unpleasant consequence: dirt and dust particles as well as water penetrate the inside of the bearings and affect their service life.

These spherical roller bearings are mounted on tapered shaft sleeves or adapter sleeves for optimum bearing clearance adjustment. Among other things, this offers the advantage that the bearings do not have to be heated and shrunk on, but can simply be pushed on. The disadvantage: the assembly or service personnel must use a feeler gauge to check the bearing clearance and thus the correct seating of the bearing. But this only works with open bearings.

NSK developed an initial attempt to solve this dilemma (open bearing and simple assembly or closed bearing and complex assembly) in 2012/13 together with an Australian sales partner and several large mining companies. In various opencast mines, where the bearings on the conveyor belt drums failed after an average of about six months, a newly developed series of sealed spherical roller bearings was installed, whose features include a highly effective seal design and a particularly durable bearing material. However, because these bearings are sealed rather than open, it is not possible to measure the radial clearance.

Now users no longer have to choose between easy mounting and limited bearing life, because NSK has developed spherical roller bearings with a removable seal. This seal is mounted in a seal carrier that is fully removable via screws, allowing access for clearance measurements with feeler gauges – and, if necessary, for inspection and lubrication with a grease of the user’s choice. This design does not require heat shrinking with appropriate heating equipment, and users can use tapered adapter sleeves and locknuts according to the ISO standard. This design is dimensionally identical to existing solutions and thus interchangeable.

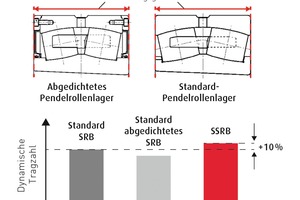

A key development objective was the fact that the bearings remain within the ISO-specified dimensions despite the removable seal, so that standard bearing housings can still be used. NSK achieved this goal by using the company’s own Hi-TF bearing material. It increases the load rating by up to 10 % (depending on size) compared to a standard open bearing. Conveyor system operators can therefore quickly and easily replace their existing open bearings (e.g. on the drive, deflection and tension rollers of conveyor belts) with the NSK spherical roller bearings; a new housing is not required.

Compared to conventional bearing steels, the Hi-TF material generally offers about twice the service life with clean lubricant. With dirty lubrication, the service life can even increase by a factor of ten. The bearings are equipped with seals made of the proven high-performance nitrile material (HNBR), which is suitable for ambient temperatures up to 100 °C, and extra-strong lip seals, which provide a 30 % more effective seal compared to concepts customary in the industry. This contributes to protection against contamination and thus to a long service life.

Since the first field tests and retrofits, NSK Australia has supplied around 1600 long-life spherical roller bearings with detachable seal technology across the country’s mining industry. A full range of standard sizes from 120 to 440 mm bore diameter is now also available in Europe. First installations have already taken place. In Australia, analyses of bearings after two years of use showed a remaining service life of eight years, resulting in a total service life of ten years. This is far in excess of anything previously witnessed by conveyor applications in the mining and quarrying industry.