Improving on the Good

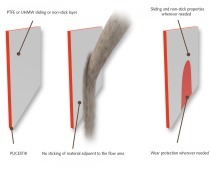

To combat the excessive wear costs in the recycling of construction rubble, Torsten Wolf, Managing Director at VBR Vogel Bau Schüttgutrecycling, and Robert Keppler, Head of Engineering at the same company, set themselves the task of minimizing the wear costs per tonne of comminuted material by adopting state-of-the-art solutions, breaking new ground when necessary (Fig.). They therefore turned to the plant supplier, initially requesting the supplier to optimize the machine lining, which could be achieved with the use of new type of roll-bond clad, extremely hard material (exceeding 650 HB). As...