Improved recovery while cutting downtime and water consumption

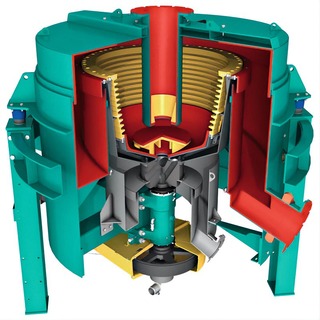

Knelson semi-continuous Gravity Concentrator

Knelson semi-continuous Gravity Concentrator

© FLSmidth

The new patented GX Cone delivers impressive recovery enhancements due to enhanced water distribution within each ring. As water enters from the base, it flows through zone separator nozzles for a customisable fluidisation profile. This allows for even distribution of water in each ring; the new design also significantly increases the active recovery surface area.

The result of this advanced distribution of fluidisation water across the entire concentrating cone is a step change in overall coarse and fine gold recovery, facilitating the highest possible recovery. Test data shows that gold recovery in all size fractions, from course to fine, improved significantly with the GX Cone. In addition, the balanced water distribution across the concentrating cone allows for a significant reduction in fluidisation water requirements while improving recovery.

The third major benefit of the Knelson GX is easier maintenance. Because it is made of a customised, abrasion-resistant and durable polyurethane compound, maintenance frequency and operational costs are significantly reduced. “The new Knelson GX Concentrating Cone is the culmination of over 40 years of research and operational experience. It delivers a win-win-win scenario: better recovery, less water use and less downtime due to easier maintenance. In short, it helps customers produce more with less resources – a central tenet of our MissionZero ambition to cut water and energy waste in mining by 2030,” comments Mike Lefler, Head of Global Product Line Manager for Precious Metal Recovery at FLSmidth.