High quality solutions for the material handling industry

Fleximat PPM is a Norwegian-Austrian based company, which delivers high quality solutions, machines and components for the material handling industry worldwide. The company was founded in the year 1980 and has a long history of delivering machines and equipment for the Nordic countries. Today the company is represented by sales partners in a broad network all over the world. The head office and factory is based in the south of Norway 20 km west of the city of Kristiansand (Fig. 1). From the Norwegian department the company organizes sales, turn-key engineering for smaller plants and the production and assembly as well as the testing of the machinery. There is also a sales and engineering department nearby the city of Graz/Austria. The Austrian office consists of a highly qualified group of engineers, specialized in vibrating products, who are engaged in sales and engineering of vibrating machinery such as vibrating screens, vibrating feeders etc.

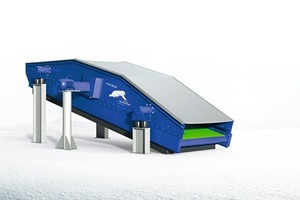

The company is represented with machines in industries like sand/gravel plants, crushing and aggregating industry, mining industry, smelting plants, process plants (steelworks/aluminum plants etc) and the recycling industry. The main competence is to be found with vibrating equipment. The company has a wide program of different screening machines for all types of applications. The standard program consists of circular motion screens (Circ-bear, Fig. 2), linear motion screens (Line-bear, Fig. 3) and Flipflow screens (Flip-bear, Fig. 4). The product range includes also other screens like sizers, dewatering screens, banana screens, special waste screens etc. The machines can also be tailor-made outside our standard range, and adapted to every unique onsite situation. All the screens are engineered in a heavy duty version.

In addition to the screening machines the company produces vibrating feeders (Feed-bear, Fig. 5). All the vibro-feeders are engineered in a heavy duty version in order to work with all kind of applications. The machines can handle even under the worst surroundings. From the standard feeder range customers can be supplied with normal flat bottom unbalanced driven machines, round body shaped machines, tubular feeder version or big primary feeders which can be equipped with grizzly sections if requested. But it is also possible to deliver tailor-made feeders, due to the knowledge that all onsite situations and material compositions can be slightly different from place to place.

Another traditional product from Fleximat PPM is conveying technology (Fig. 6). The company is able to produce and deliver belt conveyors in a various number of types – all depending on applications, and all in heavy duty as well as high quality edition. The belt conveyors can be equipped with and after customer’s request. Besides that Fleximat PPM have also a wide range of other conveying machinery such as screw conveyors, bucket elevators and vibrating conveyors etc. – everything adapted to the actual situation onsite.