Efficient solution for big bulk transhipment

Van Beek has made an important contribution to a superfast filter system for bulk powder. Wide Scope in Ghent/Belgium developed this loading and filter system and was looking for a partner to implement it. “Cooperation with Van Beek has led to a very good end result," says plant manager Gert Bert. Wide Scope specialises in handling white bulk products, such as kaolin and talc. The company has its own slurry make down plant in Ghent. The enormous quantities of kaolin that the company sends by ship, wagon or truck required efficient filtering and dust-free loading.

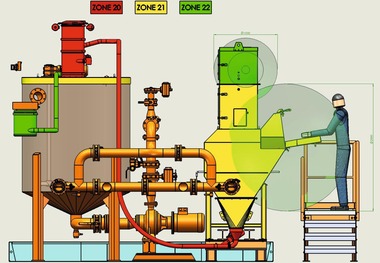

In the solution to which Van Beek has made an important contribution the powder now arrives via a hopper into an inclined screw. The screw conveyor ensures a continuous flow to a fine-meshed filter developed by Wide Scope. After filtering a second screw transfers the powder via a loading bellows into a bulk truck (Fig.). Van Beek supplied two KR400 type tube conveyors with a capacity of 50 m3/h, an inlet hopper with screening deck on the first screw conveyor and a loading bellows at the outlet from the second screw conveyor. The whole system has a cascade setup.