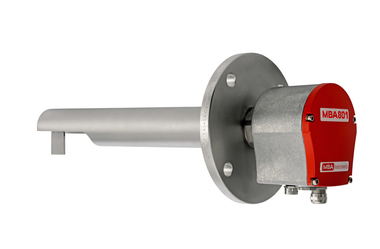

Bulk level measurement with a particular second function

Direct drive without gearbox, powerful motor with miniature paddle, selectable pre-set parameter combinations for universal use - these are the main features of the new series of rotating paddle type version MBA800 for level measurement (Fig.). The inspiration for implementation of these ideas was the MBA-owned patent for magnetic coupling (patent no.: EP1357366B1). By now, the idea of the magnetic coupling has now been developed as an integral component in permanent magnetic synchronous motors. Due to the direct drive variable-speed motor control, parameters can be coordinated in such a way that the various functions of the machine can be adjusted to the different types of bulk goods and their characteristics in the relevant application. These pre-set parameter combinations are what make the MBA800 unique. It has already proven its worth excellently in field tests. The MBA800 is available with 8 selectable standard settings, so that the device actually measures what it is supposed to measure.

For level measurement of bulk material, control optimisation of a permanent magnet stepper motor was developed in which different parameters have different settings. For example, the trigger moment of force can be set so that the device reacts highly sensitively to blockage of the paddle by bulk goods. The rotating speed of the shaft can be set. The higher the speed, the faster will the trigger increments be gone through. The area in which the shaft may move in the blocked condition can be set as well. Of course, time must not be forgotten as a settable factor for the free-running test and standstill recognition. The settings of the individual parameters that influence each other and the resulting use can be determined in pre-set customer-friendly combinations of the parameter settings as standard application settings.

The MBA808 is a rotating paddle level indicator with dual function: While the repose angle of bulk material should be considered to determine the immersion depth and installation position of the normal level measurement instrumentation, the MBA808 simply pushes the bulk material aside with its own force. It grades the surface of the bulk material by levelling it in a circular motion onto the inner wall of the silo. In this way the silo becomes increasingly fuller and the previously unused flanks of the material cone will be filled up and used. Only if no more material cones can be formed and the silo is really full, the MBA808 signals: “Silo completely full”. Due to pre-set parameter combinations, the MBA800 devices and the special application MBA808 is very easy to adjust regarding applications and bulk material characteristics.