A key to optimal performance

General requirements

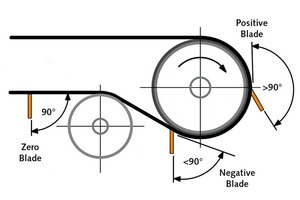

A discussion about belt cleaner tensioners must include the basic approaches to belt cleaning, as the most effective approach is achieved through a combination of cleaner and tensioner designs. Industry has gravitated toward mechanical cleaners and tensioners because they are simple and economical. The most common mechanical belt cleaner designs present a blade or brush at various angles to the belt. Depending on the cleaner type and materials of construction, they can approach the belt at either a positive, negative or zero rake (Fig. 1).

Regardless of the basic cleaning approach, maintaining the optimum range of contact pressure will result in the best balance between cleaning performance, cleaning element wear, belt wear and power requirements. CEMA Standard 576, Classification of Applications for Bulk Material Conveyors Belt Cleaning, provides a performance-based classification system for use in specifying belt cleaners.

Basic approaches to tensioning

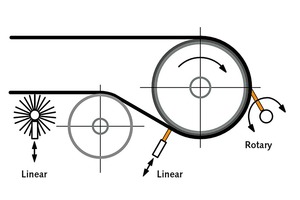

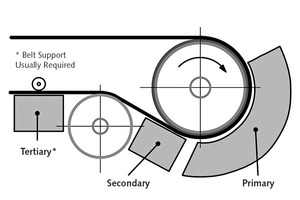

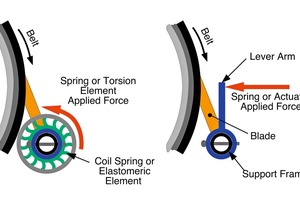

There are two basic approaches to applying tension to the belt cleaner: linear and rotary (Fig. 2). The blade’s angle of approach to the belt often dictates whether a linear or rotary tensioner is applied.The stored energy that creates the tensioning force most often comes from gravity, springs or actuators. CEMA defines the cleaning positions as Primary, Secondary and Tertiary (Fig. 3). Most belt cleaners mounted in the primary position utilize a rotary style tensioner, while most belt cleaners mounted in the secondary or tertiary positions use linear style tensioners.

Linear tensioners

Linear tensioners are most often applied where the compensation for wear is required in small increments, such as with hard metal-tipped cleaners located in the secondary cleaning position or with brush cleaners. The basic tensioner design approach is typically a carriage that constrains the support frame but allows linear movement along a guide or guides roughly perpendicular to the belt surface, with the support frame and blade design providing the cleaning angle. Some designs incorporate a relief ability for impact by splices or belt defects.

The advantages of linear tensioners include:

Simple in design

Can be engineered to one setting for full blade wear

Access windows are easily incorporated within the mounting footprint

Can accommodate actuator deflection scales for accurate adjustment of cleaning pressure

Delivers the ability to adjust for uneven mounting positions or asymmetrical blade wear

The disadvantages of linear tensioners include:

The tensioner footprint can be large, restricting options for ideal belt cleaner installation

There must be access to the far side for adjustment

The guide mechanisms are subject to fouling from dust and corrosion

Changing from bottom adjustment to top adjustment or providing for adjustment from one side complicates the tensioner design

Rotary tensioners

Rotary tensioners utilizing an actuator are principally designed using a lever arm or an elastomeric element that is concentric with the belt cleaner support shaft. They apply a blade-to-belt contact surface determined by the actuating force and linkage geometry. The energy source delivers a force to the lever arm which rotates the shaft and forces the belt cleaner blade(s) against the belt surface. Rotary designs tend to be compact and, in most cases, the actuator(s) can be mounted at any orientation, which provides options for installing the belt cleaner in the optimum position.

Counterweight tensioner

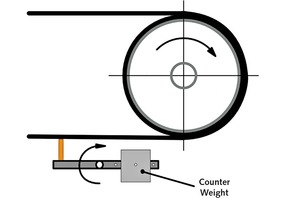

At one time the most common rotary tensioner was a counterweighted lever arm, with its position adjusted to apply the design cleaning force to a blade or blades that contact the belt. A counterweight can be mounted on one end of the shaft or both. Usually, the initial installation would have the arm angle set so that at the midpoint of the blade wear the arm would be horizontal, thus roughly averaging the design cleaning force over the life of the blade (Fig. 4).

The primary advantage of the counterweight design is that it is self-adjusting by gravity. The disadvantages of the counterweight design are:

The lack of damping which allows the blade and therefore the weight to bounce when struck by a splice, strongly adhered material, like ice or a defect in the belt. The unexpected movement of the counterweight can represent a safety hazard and uncontrolled bouncing can result in belt top cover damage

The counterweight tensioner takes a significant amount of space

If the counterweight arm cannot be mounted horizontally there is a reduction in the force applied to the blade, because the effective lever arm is shortened

Rotary lever arm and actuator tensioners

Rotary adjustment of the belt cleaning blade can be accomplished in several ways. The support frame is almost always in a fixed location but free to rotate. The required tensioning forces can be applied by many types of actuators, such as: springs, fluid cylinders, electric actuators or from torque stored in an elastomeric element. Rotary tensioners are often used with elastomeric blades, where the change in blade height and thickness as it wears is significant (Fig. 5).

The advantages of rotary tensioners are:

A compact design

A single tensioner mounted on one side of the conveyor can often be used for a range of blade styles and belt widths

They can be designed to minimize the number of times the tensioner has to be adjusted during the life of the blade

Many types of actuators can be used

The disadvantages of rotary tensioners are:

There can be a safety hazard if the support frame is mounted too far from the pulley and the cleaner pulls through

The mounting location of the axis of rotation is critical for proper blade cleaning angle

The constant force output by some actuators can result in a wide variance in cleaning pressure and blade life over time

When a tensioner is required on both ends of the support frame, it is often difficult to access the drive side of the conveyor for mounting and adjustment

Other factors

The importance of proper installation should not be overlooked for the proper performance of the belt cleaner. Slight variations in the location of the support frame relative to the belt can cause significant issues with the effectiveness of the blades and can result in support frame bending. Most manufacturers provide detailed instructions for the location of the support frames and tensioners, which must be followed for optimal function.

To be effective, belt cleaners should be frequently inspected and maintained. In practice, the design of the conveyor structure and location of the drive and other equipment makes service difficult. Consideration in the design stage for easy access and ergonomic location of the cleaners for inspection and service will pay dividends in reducing carryback, maintenance time and potential exposure to injuries.

To maximize blade effectiveness and minimize rapid wear, the recommended adjustment protocols should be followed. Studies have shown that there is a critical cleaning pressure range for various types of cleaners and blade types. These studies demonstrate that over-tensioning the belt cleaner does not necessarily improve the cleaning effect, but often results in increased belt and blade wear as well as higher power consumption.

The future of cleaner tensioning

As technology continues to advance, suppliers are beginning to integrate an increasing level of functionality in belt cleaner designs. One such innovation is a belt cleaner position indicator that can monitor the blade and estimate remaining service life based on the current hourly wear rate. Able to retrofit directly to existing mainframes, the device is capable of sending a notification to maintenance personnel or service contractors when a cleaner requires re-tensioning or replacement.

This capability brings a number of benefits. Inspection and service time is reduced, as maintenance personnel no longer need to physically view the cleaner to determine the tension or wear status. It also reduces the time workers need to spend near the moving conveyor, helping to minimize the potential for accidents. By relying on data – not human judgement – to maintain the appropriate tension for optimal cleaning performance and monitor blade wear, the indicator maximizes service life and reports with certainty when a blade is nearing the end of its useful life, delivering a greater return on cleaner investment. Replacement orders can be scheduled for just-in-time delivery, reducing the need to stock parts inventory, and installation can be scheduled for planned downtime instead of on an emergency basis.

Taking the technology a step further is another patent-pending device that combines the position indicator with an automated tensioner. This novel powered assembly incorporates sensors that constantly monitor blade pressure and adjust its position to maintain optimal cleaning tension. Maintenance personnel no longer need to visit each cleaner and manually re-tension. Instead, the tasks are performed automatically, reducing maintenance time while maximizing the usable area of every cleaner. Analytics provide an unprecedented view and understanding of belt cleaner performance, with real-time data available remotely via a specially-designed app.

Conclusion

While manufacturers continue to improve belt cleaner effectiveness, it has become clear that there is no single or ideal solution for belt cleaning and tensioner selection. Safety of personnel and the belt itself is an important consideration when selecting a tensioner. Ease of inspection and maintenance is critical for belt cleaner effectiveness, so the tensioner must allow for quick and safe service.

The selection of a belt cleaner should be based on the duty rating of the cleaner as provided in CEMA Standard 576 and then the appropriate cleaning system selected. The system should be selected based on life cycle cost and not just the initial price. The investment for effective belt cleaning is justifiable on direct cost reduction (cleanup costs), extended component life (often 25 % to 40 %) and reduced exposure to injuries, which is directly related to reduced cleanup frequency.

Author:

R. Todd Swinderman, P.E & CEO Emeritus,

Martin Engineering