AUMUND Group Field Service uniform global standard

Two AUMUND Group Field Service team members during commissioning of SCHADE Wagon Tippler Unloading Units at Taman Seaport

Two AUMUND Group Field Service team members during commissioning of SCHADE Wagon Tippler Unloading Units at Taman Seaport

© AUMUND

By bringing together approximately 60 supervisors working all over the world into one organisation, a global network has been created which allows immediate deployment of local technical personnel to any customer. The assignments are supported by supply of spare parts from five Service Centres, located in Germany, Hong Kong, USA, Brazil and Saudi Arabia. As a result of their international expertise and experience, the Field Service supervisors are often booked for installation and commissioning assignments on bulk materials conveying equipment from other manufacturers.

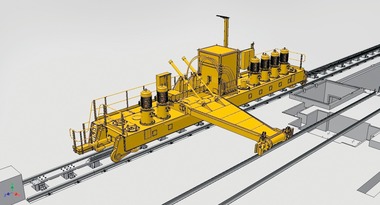

Commissioning of the first SCHADE coal handling lines at Taman Seaport

At Taman Seaport, built by OTEKO Portservice in the Russian region of Krasnodar on the Black Sea, two new coal handling lines have been commissioned, with AUMUND Group Field Service GmbH playing a major role. The company received an order for supervision of both the mechanical and electrical installation of the Wagon Unloading System supplied by SCHADE Lagertechnik GmbH. The SCHADE system unloads coal in one single tipping operation from two sets of three wagons which are coupled together, with two Triple-C-Frame Wagon Tipplers working in parallel.

Taman Seaport has been expanded in recent years and is now the second largest freight handling port in southern Russia. In October 2019 President Vladimir Putin inaugurated the new coal unloading lines with the two SCHADE Triple-C-Frame Wagon Tipplers. Commissioning of the Wagon Tippler Unloading Units took place between December 2019 and November 2020. In this phase around 4 000 000 t of coal was unloaded.

Over the next few months more work is to be done at Taman Seaport, which will require the attendance and support of the Field Service supervisors, this time for the installation of two SCHADE Semi-Portal Reclaimers for sulphur storage, and for the commissioning of a SCHADE Pivot-Frame Wagon Tippler for handling sulphur.

The order from OTEKO Portservice to SCHADE also comprises two more Triple-C-Frame Wagon Tipplers and two Semi-Portal Reclaimers. The expertise and experience of the Field Service supervisors will also be required for the installation and commissioning of these machines.