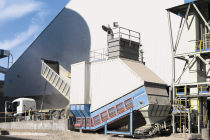

Armoured chain conveyor for salt mine

Early this year the company KD Maschinen- und Stahlbau GmbH from Bernterode, Thuringia, will be commissioning an AUMUND armoured chain conveyor type PKF (Fig.) in an east German salt mine. The unit has a centre distance of 13.5 m and conveys 150 t of potassium chloride per hour. The machine will be delivered, installed and commissioned in March of this year.

The AUMUND conveyor was chosen owing to its low build-height. As the unit will be employed underground to extract potassium chloride (road salt) from an intermediate bunker, the footprint and in particular the build height were deciding factors. The total weight of 22 t will be packed in handy-sized units, delivered to Breitenworbis in northern Thuringia and then be transported, piece by piece, through the depths of the mine shaft prior to reassembly.

The tension element of the armoured chain conveyor consists of especially quenched and tempered round steel link chains. Three chain strands are used in total. With the related scrapers, which are also quenched and tempered, they achieve a discharge width of 1000 mm. The material is conveyed in the upper run on a wear-protected base plate. Spillage is received in the empty lower run and conveyed back into the transport flow. With this design additional cleaning scrapers become superfluous. At the same time a low build-height can be achieved which is of great importance especially for underground operations.

AUMUND armoured chain conveyors are normally used for bunker discharge applications when only limited space is available. They transport easy-flowing bulk materials as well as sticky raw materials such as chalk, gypsum, marl or clay.