Wear protection precautions for equipment at Deutsche Steinzeug AG

Deutsche Steinzeug AG is one of the best-known producers of ceramic coverings in Germany. Its portfolio includes products such as wall and floor tiles, but also swimming pools and façades, most of which are manufactured at German sites. At its manufacturing plants at Sinzig and Alfter-Witterschlick, environmentally friendly manufacturing equipment is installed, including mills for grinding the raw material to the particle size required for further processing.

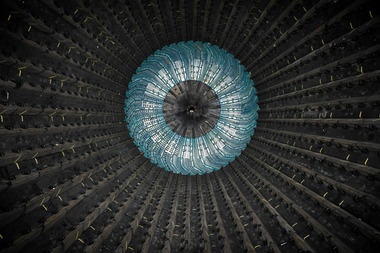

For this purpose, the company uses Contimillls, which are filled and emptied in one operating cycle (Fig. 1). A hose pump constantly conveys slurry into the mill. Deflocculants and water are added by means of metering pumps. The raw material, which also includes damaged tiles, is fed from the top via a feed hopper into the mill. Inside the mill, around 36 t flint pebbles as grinding media play an important part in the grinding process. During filling without interruption, on every revolution of the mill (around 1 000/h) the material moves slightly further to the other side in the direction of the discharge. Here in the slotted discharge walls are screens that prevent the escape of material that has not been sufficiently ground. All operations (blunger, slide gate, pumps, metering equipment as well as the contimill) in the grinding process are computer controlled.

Apart from two dates in the year, there is practically no interruption in the milling process at the plant in Bonn. Then the mills stand still for around two weeks. During this time, REMA TIP TOP Material Handling works for Deutsche Steinzeug to perform maintenance and repair works on the mill linings inside the grinding drum. Before, at different points the remaining rubber thickness of the linings was measured to then determine the effective wear in the period that has lapsed since the last maintenance with special analysis programs (Fig. 2). The next time, the procedure is repeated. Determining the wear condition is part of a comprehensive service programme: REMA TIP TOP Material Handling GmbH offers manufacturers uninterrupted lifetime of the mills between the maintenance stops.

Immediately after the evaluation of the wear measurement, the decision is made whether and, if yes, when wear components in the interior of the mill must be replaced (Fig. 3). The time frame for such follow-on work is generally a maximum of two weeks. The replacement of individual mill lining components must be performed promptly in the interest of planned capacity utilization of the plant and operations.

The optimum lining of the mills for protection of the outer metal casing can be determined based on the material, rotational speed, grinding media and other important factors. The same applies to the degree or progress of wear of the respective lining material and its form (Fig. 4). Here REMA TIP TOP Material Handling always recommends modular rubber elements as mill linings that are made to meet the individual requirements of the mill.

Premature damage to the metal casing caused by a defective protective lining would cause costs for the operator that are far in excess of the regular expense for maintenance and lining. A service or maintenance schedule like that followed by Deutsche Steinzeug AG, however, is not used by all rock mill operators in Germany. When holes appear in the outer casing, it is already too late. If the in any case late acoustic signals are not or not correctly interpreted, then in extreme cases the complete mill can fall apart. In such a situation, life and limb are in danger.

Today it is known that mill linings made of rubber have clear advantages over mills with a bricked interior. On the one hand, the thicker wall compared to rubber limits the available interior volume, which substantially lowers the productivity of the mill. On the other hand, the wear is much higher and the repair of damage is more expensive. Moreover the much higher weight of the brick lining leads to a much more negative energy balance of the entire plant. The service provider REMA TIP TOP Material Handling based in Kamen recommends if required more sensible alternatives and calculates for conversion of a lining the economic benefit for the entire plant – completely independent of the type of mill. In some cases, such a conversion pays off already after 1 or 2 years.

Depending on the application, the secure fixing of the rubber lining is also of great importance (Fig. 5a-c). If a part becomes loose in a mill and is comminuted during the grinding process, the rubber can contaminate the ground product. It is hardly possible to describe the ensuing damage.

The wear can be bindingly determined by REMA TIP TOP Material Handling on site within just a few minutes. Manual errors in the measurement can be eliminated by the analysis programme with a plausibility check. The assessment is free of charge.