A foundry with tradition

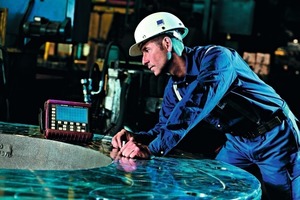

A foundry was commissioned on this industrial site nearly one hundred years ago. Today Stahlwerke Bochum GmbH (SWB) is one of the world's leading and most productive foundries of its type. The company, with its many years of experience, specialises in the development and production of wear-resistant tools for the preparation, comminution and recycling sectors.

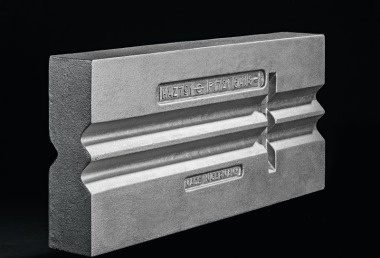

SWB products are used in all crushers and preparation systems exposed to the highest levels of wear, assuring maximum resistance to abrasion, erosion and impact. One of the main fields of application for SWB wear parts can be found in the comminution and preparation of secondary materials; they are responsible, for instance, for ensuring that the scrap obtained from life-expired vehicles is converted to feed material for new steel strip, and produce filling materials for the construction of new highways from building rubble and comminuted asphalt.

The AT INTERNATIONAL editorial team met Uwe Spiecker, general sales manager at Stahlwerke Bochum GmbH, for an interview focussing both on SWB‘s economic development, on its most important business sectors, and on the future of its anti-wear products.

Uwe Spiecker: At the moment, following the past financial and economic crisis, we are currently undergoing a recovery phase. Our markets are exhibiting differing rates of growth. We are satisfied with recent developments, where they affect us, but we are still below the high level achieved in the 2007/2008 business year.

Uwe Spiecker: We have a broad and diverse range of products, and this enables us to balance out any fluctuations in individual sales markets by means of the other sectors.

Predominantly long-term business relations, and our proverbial customer orientation, enabled us to develop and implement individual supply concepts jointly with our customers to bridge the period of the financial and economic crisis.

Uwe Spiecker: Diversification, adaptability, customer orientation, and adequate liquidity.

Uwe Spiecker: Our company‘s most important business sectors are scrap recycling, accounting for around 70 % of total turnover, and the mineral resources industry, including construction waste recycling, which makes up 30 % of sales.

Globally rising demand for feed materials, coupled with increasingly scarce resources, mean that demand for secondary materials will continue to grow. This background has positive implications for demand for the products which Stahlwerke Bochum GmbH makes.

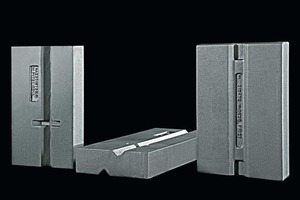

Uwe Spiecker: It‘s of decisive importance for corporate success to always be one step ahead of the competition. Research & Development are therefore part of the company‘s core activities, both in the materials sector and in the further development of wear-resistant cast tools and components. Another interesting project on which we are currently working are our “Manuals”. These collate practical experience and pass it on to our customers, in order to help them in optimising their own machines and facilities.

Uwe Spiecker: In 1990, wear parts for scrap preparation, including other metal recycling activities, accounted for around 25 % of total turnover. This has now risen to figures constantly above 70 %, which illustrates the importance of this sector to our company.

Uwe Spiecker: Germany as an industrial location continues to provide important advantages in the context of tough international competition: consistently excellent production quality, assuredness of supply, and product innovation. Products “Made in Germany” continue to enjoy high acclaim around the world, as can be seen from the fact that, measured by turnover, some 75 % of our company‘s products are now exported.

Uwe Spiecker: The desire of the populations of the so-called BRIC states for individual mobility will rise continuously, as will the necessity for the expansion of the existing and the creation of additional infrastructure. The same applies, after a time lag, to the present-day developing countries. Both the BRIC states and the current developing countries are the future markets, in terms of growth potential, for our company‘s business sectors. The established markets in today‘s leading industrial nations will continue to be of great importance to us, however.

Uwe Spiecker: We are globally active, and we are supplying virtually continuously to South America, the USA and Japan in the field of scrap reprocessing; recycling has a ranking similar to that in Central Europe in these regions. China is also an interesting market, there are already individual major projects under way there.

AT INTERNATIONAL: How do you envisage the basic development in the disposal and recycling industry?

Uwe Spiecker: Our planet‘s reserves of feed materials are finite, and landfill capacities are limited. The secondary raw materials it produces are increasingly gaining importance for the disposal and recycling industry, which is already an essential element in the modern economy, and will be even more vital for future generations.

Uwe Spiecker: The highly wear-resistant cast tools and components produced at Stahlwerke Bochum GmbH are used around the globe in the scrap recycling and minerals preparation industries. Our references are all renowned companies active in these sectors, along with a large number of small and medium-sized enterprises, who have been part of our customer base for decades. Around the world, there are only few life-expired vehicles that are not comminuted by shredder hammers which we have delivered, and only few infrastructural projects in which the mineral materials fed are not compacted to the right, cubic geometry by our crusher plates.

One particularly notable example of the use of our products was a large series of crusher heads for the impact roller crushers that were used to break the Berlin Wall down into reusable ballast.