The next dimension in packaging

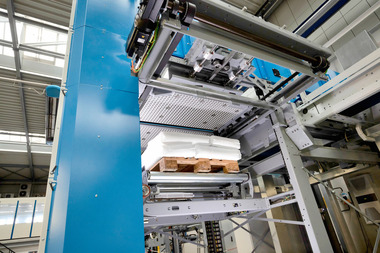

The BEUMER stretch hood® i (Fig. 1) is the next generation of end-of-line pallet packaging systems to be introduced to the market by the Beckum-based intralogistics specialist. The system offers reduced energy consumption and has a smaller footprint, creating a more efficient work routine. Optimised controls allow the machine to be operated intuitively. These new developments also mean an improved price-performance ratio.

Over the years, the safe, secure and stable transportation of goods has always been – and remains – increasingly more important for companies in industries such as chemical, construction material, and food and beverage alike. BEUMER has always understood the need for effective palletizing and packaging solutions, and in the 1980‘s introduced the BEUMER stretch hood®, a high-performance end of line pallet packaging solution that has provided customers worldwide, a sustainable, customisable solutions for their products protection.

Packaging palletised goods with the BEUMER stretch hood® is quick, safe and secure. The machine’s innovative control technology allows various stack heights to be recognised automatically and allows the machine to adjust flexibly. An ultrasonic sensor determines the required film length. The film is then cut and sealed along the cut edge. This forms a hood, which is crimped, pulled over the stack and down underneath the pallet (Figs. 2 and 3) so that it fits the entire stack snugly and provides stability. This quick and efficient packaging process protects goods from the environment, water, dust and insects. The palletised goods are clearly visible due to the smooth surface of the transparent, highly flexible film.

BEUMER has now completely overhauled this high performance packaging machine. The result is the new BEUMER stretch hood® i. This latest generation offers more than just improved sustainability by using less film and consuming less energy. The machine is also easier to service due to a “one-for-all” maintenance concept and the flexibility to change operating parameters. An intuitive human-machine interface simplifies operation and makes quick work of film roll changes (Fig. 4). Improvements were made to how space is utilised, reducing the machine‘s footprint by 30 %. This high-performance packaging machine retains the customary precision and quality of the BEUMER stretch hood® generations S and M, and boasts an improved price-performance ratio.

BEUMER made sustainability a priority when developing the stretch hood® i. For comparison: its predecessor was capable of handling a minimum film thickness of 60 µm – the BEUMER stretch hood® i can handle film that is 40 µm thick. This flexibility significantly reduces consumption costs while helping to reduce environmental impacts. Energy consumption is reduced by 12.5 % and compressed-air consumption by 53 % compared to the two previous models. This also contributes to reduced consumption costs and reduced environmental pollution considerably.

Installation space for the BEUMER stretch hood® i is more than 5 square metres less than for the S model and 8 square metres less than for the M model, which provides optimisation of production space. The system height is also 8 % shorter, an advantage for installation in limited spaces or integration with existing machinery. The reduced height means to lower capital costs. BEUMER was also able to expand the range of products that can be handled by the system. The BEUMER stretch hood® i can handle smaller pallets, such as quarter or half pallets, with acceptable pallet sizes ranging from 1320 x 1320 millimetres, down to 500 x 500 millimetres. BEUMER was also able to improve positioning accuracy by adjusting the crimping bows to be lowered closer to the stacked product. This is gentler on the film, because it eliminates interference contours, and also places the film more precisely on the stack.

2 A new drive concept

The BEUMER stretch hood® i is equipped with an innovative motion control system based on decentralised servo technology. In the past, the machines available on the market had three-phase motors; three-phase motors with frequency control, pneumatic or even, to some extent, hydraulic actuators. The motion control system allows for the permanent or – depending on the machine status – temporary connection of servo axles using electronic gear units, which simplifies the setting of machine parameters considerably. For example, on the BEUMER stretch hood® i, the user only needs to enter one set point for the film feeding speed. All servo axles involved adopt this setting and move in synch – even when accelerating and braking.

Decentralised servo technology taps into major potential for energy conservation as defined by sustainability. The energy efficiency of synchronised servomotors is better than the minimum efficiency standard level IE3, according to the IEC standard 60034-30. A DC bus between the motors allows energy to be exchanged between energy recovering motors when braking, and energy consuming motors. Troublesome braking resistors necessary for frequency-controlled motors can be eliminated. Synchronised servomotors also significantly reduce wear and tear. All starting and stopping processes are, for instance, performed using S-ramps. This places less stress on the machine and extends its operating life span. The brakes on the motors are non-wearing, because they are used solely as holding brakes. Furthermore, the decentralised design greatly reduces the amount of wiring, which is particularly advantageous when supplying power to mobile machine modules.

BEUMER has also effectively optimised the working environment with its new construction series. The improved user interface concept simple, intuitive navigation, while enhancing ergonomic work. This means that extensive personnel training is significantly reduced. Additionally, the machine adds to the pleasant working conditions with its low operating noise level, – less than 73 dB(A), making it quieter than the S and M models of the BEUMER stretch hood®.

With the new generation, BEUMER stretch hood® i, the intralogistics specialist is giving its customers improved system performance and increased availability. The machine can be serviced and operated from one side – so the user can access the machine quickly and safely. Only one tool is needed for routine maintenance, and it is supplied by BEUMER in a readily accessible spot on the control cabinet.

The time it takes to change the film roll was reduced from 15 to 8 minutes. Films of the same format can even be changed in 2 minutes. Another option is automatic film roll changes. Due to a central set point on the machine, the BEUMER engineers were able to significantly improve film behaviour.