New installations in Northern and Eastern Europe

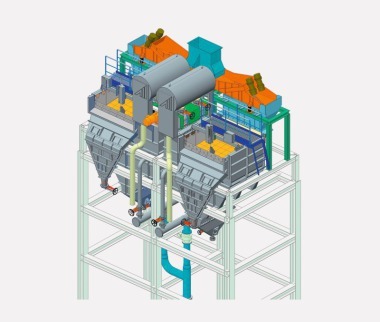

Europe‘s largest stainless steel plant in Tornio, Finland – producing 1.7 million t/a – recently opened a new slag processing plant in September 2010. The main components of this new plant are two powerful alljig®-jigging machines (Fig.), ordered by Tapojärvi, which runs the plant on behalf of Outokumpu. The slag, a by-product of steel production, still contains 5 -10 % metal, and the alljig®-jigging machines separate out this valuable metal for metallurgical reprocessing. The other product is metal-free slag that can be used as aggregate. As raw materials are becoming increasingly scarce, there is a growing trend toward economical processing of by-product slag from ferrochromium, ferromanganase and stainless steel production. In turn, there has been a noticeable spike in demand for alljig®-jigging machines, particularly in Northern and Eastern Europe.

Air-pulsed alljig®-jigging machines take advantage of gravity by using the difference in metal and slag density to efficiently separate the two. These machines from Germany are designed for capacities of 50-100 t/h, while efficiently sorting particles ranging in size from 1 mm to 32 mm.

The Finnish corporate group Outokumpu is one of the largest producers of high-quality stainless steel worldwide. Its yearly melting capacity is around 2.5 million t, and its rolling capacity for warm and cold strip, long products and quarto metal sheets is just under 2 million t. The plant in Tornio is the affiliated group’s largest factory, and is unique in that it has the only fully integrated production line. The aforementioned production line starts in the EU’s only chromium mine in Keminmaa, where approximately 200 000 t of lump ore and 400 000 t of fine concentrate are produced every year. The steel plant has 2 production lines: one with 100 t and the other with 150 t and converters in which the melted ferrochromium is processed with steel scrap. The warm rolling factory prod-uces steel with widths ranging from 1 to 1.6 m and with a thickness of up to 12 mm. Most of the coils made there are then turned into acid-resistant stainless steel sheets and plates at the cold rolling factory for customers all over Europe.

allmineral Aufbereitungstechnik GmbH & Co. KG,

Duisburg (D), Tel.: +49 2066 9917-0, www.allmineral.com