Mobile crushing plants in granite quarries

Today, mobile crushing plants are also used in granite quarries (Fig. 1). The blasted rock debris is locally crushed to transportable sizes. Up to ten V-belt pulleys are driven synchronously at a speed of 1500/750 rpm. The rock is finally crushed by means of four to eight vertically arranged steel swords. To crush even the hardest granite blocks, manufacturers use torques of more than 2000 Nm. Due to these high torques the mobile crushing plants (Fig. 2) are equipped with an overload protection, which protects the entire plant against a complete breakdown and extremely high repair costs if foreign bodies (steel) enter the system. In the case of an overload suddenly occurring, the gearbox and the motor, in addition to the V-belt, may also be seriously damaged. Safety couplings arranged between the motor and the V-belt pulleys are described below. They make it possible to shut down the plant quickly in case of an overload.

R+W Antriebselemente GmbH offer a mechanical safety coupling for maximum protection against the destruction of drive system components. When being designed the safety coupling is dimensioned, for example, via the breakdown or pull-up torque of the motor around the factor 1.3-2.0. If a crash is on the way during normal operation, the torque in the drive system increases disproportionately. The coupling will separate the driving side from the driven side within milliseconds thus preventing a total failure of all components. The maintenance-free operating principle of the coupling, which, first and foremost, allows re-engaging, ensuring the recommissioning of the plant within minutes.

coupling systems

The problem described has been known for decades in heavy-duty machine building. The designer has the choice of using shear pin couplings or hydraulic couplings. The disadvantages, compared to the mechanical safety coupling from R+W, are obvious. Certainly the purchase price of a shear pin coupling is more favourable, but for recommissioning a much longer longer erection time is needed. The pins (usually including bushes) have to be dismantled completely. Then the coupling has to be realigned before the new pins including bushes can be mounted again with enormous erection expenditure.

The initial advantage of the favourable purchase price will be relativized with the first release process at the latest. At first an overload coupling operating on a hydraulic principle collects points due to an extremely compact design. If the coupling disengages due to an overload, the oil under a pressure of up to 1000 bar is thrown out of the coupling through various shear valves resulting in serious contamination of the machine parts in close vicinity to the coupling. After the plant downtime the individual valves have to be replaced and filled by a special pump (exact pressure indication). Here the exact pressure must be maintained because otherwise the disengagement torque will be changed. In the case of an overload, this hydraulic safety coupling separates the driving from the driven side to go down to the rated torque, but free running of the individual components only takes place after a certain time lag. Possibly this may lead to further damage to the components.

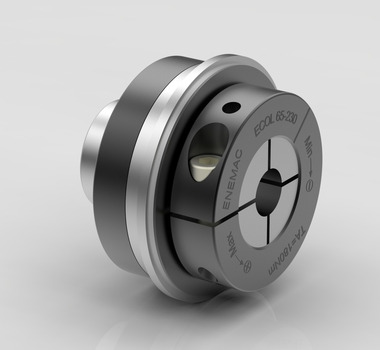

The mechanical safety coupling from R+W (Fig. 3) relativizes all these disadvantages. The mechanical operating principle (disc springs) can be reused immediately. It is not necessary to replace any wear parts, such as bolts or valves. There is no contamination of components. The most important thing, however, is that the fitter or the plant operator has a 100 % certainty that the coupling will separate exactly at the re-quired torque during a repeat case of damage. An incorrect recommissioning is excluded when using the principle of R+W.

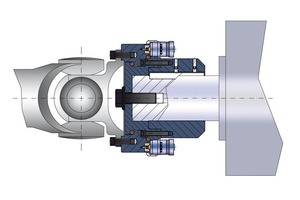

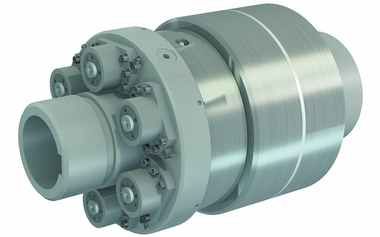

The safety coupling of the type ST has been developed for indirect drives (series ST1). Technical parameters such as radial transverse forces due to sprockets or belt pulleys are compensated by special deep-groove ball bearings. These bearings make it possible that an almost unlimited time is available for slowing down the individual gyrating masses up to standstill. The main types of connection of the series ST1 are articulated or Cardan shafts, respectively. These connecting elements are mainly used for power transmission in the heavy engineering industry. Due to the compact design, the outside diameter of all the Cardan shafts is only insignificantly larger. As connection to the usually smaller DIN flanges of the Cardan shaft they offer a simple solution with a connecting flange (Fig. 4).

In addition to indirect drives, two other models for direct drives are available on the market. The series ST2 has a flexible balancing element in addition to the safety segment. The material of this balancing element, i. e. natural or synthetic rubber, compensates for the occurring misalignments in axial, lateral and angular direction. In addition, torque shocks or vibrations are filtered. The second series for direct drives (model ST3) is offered in a torsionally stiff design. Features are an exact torque transmission, very high ruggedness and the compensation of all three types of misalignment with very low restoring forces.