Pilot Crushtec (SA) (Pty) Ltd.

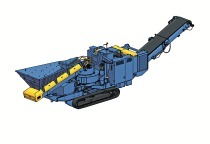

Twister VSI crushers of the South African based Pilot Crushtec use two variations of crushing. The first involves vertical shaft impact crushing, with rock being fed into a table type rotor which then accelerates and discharges the rock at high speed, against steel anvils, in the crushing chamber. The impact of the rock hitting the steel anvils induces fractures, causing the rocks to break apart. The second variation called vertical shaft autogenous (VSA) crushing sees the rock being fed into a multi-port rotor which accelerates and discharges the rock at high speed against a rock filled crushing chamber. The impact of the rock on rock fractures, breaks and shapes the rock. Bauma will also see the exhibition for the very first time of Pilot’s exciting RubbleBuster, which offers a cost-effective, and quality solution to Europe’s tough

new construction and demolition waste legislation. The RubbleBuster allows for the reprocessing of waste material on site and its compact design allows for easy access and storage on tight sites.

Open air F7, Stand N710/2, www.pilotcrushtec.com