The future of VSI

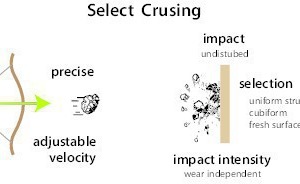

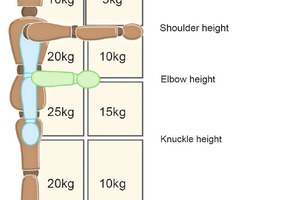

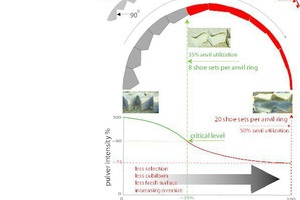

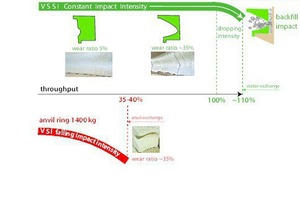

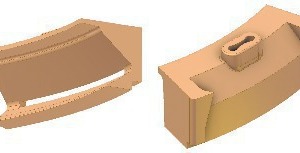

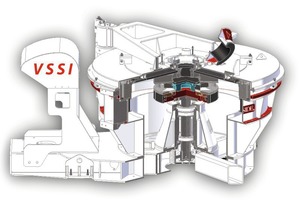

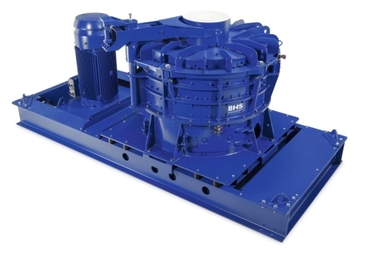

SimplifiedSummary: The VSI concept is simple and applies impact loading, necessary for the production of high quality aggregates for asphalt and concrete. But the VSI does not live up to its expectations in its traditional configuration with shoes and anvils, which is a very difficult combination, expensive to run and quality drops when the anvils start to wear off. Moreover, the shoes have to be exchanged manually but weigh more than 40 kg, far above the maximum handling weight of 20-25 kg, recommended by international Health and Safety authorities. A new technology is now available that solves these problems in surprisingly easy way and at much lower operational costs, providing the VSI a new future. Major simplification is here the key element.

Quality aggregates

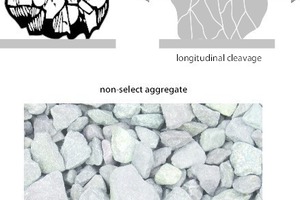

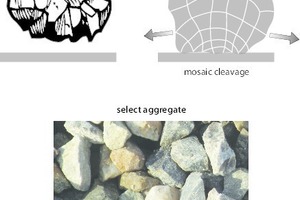

Quality aggregates for the production of asphalt and concrete require that the broken particles are strong, have a uniform structure and are cubiform with fresh surface texture.

Aggregates make up to 90 % of asphalt and about 70 % of concrete volume, and have therefore a profound impact on the quality of asphalt road works and concrete structures. For example, the workability during placing, stress distribution, durability, and the contact between tires and the road surface, are among the properties strongly affected by the aggregates.

Before rock material is quarried it has...