New tempering method

With the new LongLife tempering method from Craco, screens and cutting edges made from the premium-grade wear steel Cracox can be additionally hardened. The process is applied primarily to those areas exposed to the highest wear stresses. With this method, a 500 hardness Brinell (HB) Cracox steel can be turned into a 600 HB steel at the treated areas.

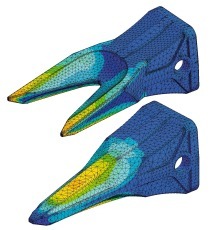

The Linz-based Austrian bag Basalt AG, a customer of Craco GmbH for over a decade, consists of six subsidiary manufacturing companies with numerous production sites at which Craco products are used. Thanks to the LongLife tempering method, the durability of, for example, cutting edges on wheel loaders (Fig. 1) at ballast processing plants could be improved. With the wide spectrum of applications for cutting edges, the advantages lie mainly in the hardening of fibres. As a result, the edges (Fig. 2) are sharper longer and lifetime increased. For screens the main benefit is that the perforations keep their shape longer and the edges remain sharp. Firstly, this guarantees a longer lasting consistent quality of the finished product, and secondly it noticeably increases the useful life of the screen.

Cracox is used exclusively as a base material for LongLife-tempered products. The highly wear resistant special fine-grained steel is rated a premium-grade steel. Around 8 000 t of this are used in the wear protection sector every year. Cracox combines high hardness with high apparent yield limit and tensile strength thanks to innovative alloying. Its good, economic machinability and outstanding wear protection properties were the main reason for Cracox being awarded the Innovation Prize by the German state of the Rhineland-Palatinate.

CRACO GmbH, Atzelgift (D),

Tel.: +49 2662-9552-0, www.craco.de