The right solution for any condition

The Quickborn-based SMB International GmbH is one of the leading suppliers of harbour transhipment systems. Engineers design shiploaders with different loading heads depending on the product, e. g. the fragility, self-inflammability or dust formation and environmental conditions such as wind, cold, heat or seismic activities. The different SMB loading heads may be combined with the various types of shiploaders, such as mobile or stationary loaders as well as combined loaders. Selection criteria are, for example, the amount of the product or if a product easily absorbs moisture as well as the size of the vessel to be loaded and its condition.

This alternative is characterized by a rotary table including bag-guiding system driven by an electromotor and arranged at the end of a spiral chute (Fig.). The bags may be discharged in a radius of 2 m with a frequency of up to 2400 bags per hour. By means of remote control the operator swings the chute and the loading head over the loading point and stops a few centimetres above the planned loading position. The rotary table of

3 m is discharged gravimetrically. The discharge position from the rotary table is within a radius of 270 °. This position is manually adjusted by the operator during operation by means of a handle on the transfer conveyor. This alternative is advantageous when loading smaller barges since the bags do not just fall down but are guided exactly. Thus, a destruction of the products is excluded. Furthermore, the loading head is very cost-effective. A disadvantage is the limited radius, i.e. the entire loading system must be shifted frequently. The bag loading head including the rotary table is suitable for cement for example.

Easy loading of bags is possible with the bag loading head including the telescopic belt conveyor. A swivelling rotary table (up to 270 °) including the bag-guiding system is arranged at the end of the spiral chute. From there up to three telescopic belt conveyors transport the bag to the vessel within a radius of 7 m. It is also possible to install a telescopic rotary spiral chute. In this case the loading head can be used in a range of 360 °. One operator will move the jib by means of radio remote control; another one will guide the bags into the cargo hold without any physical strain. The goods to be loaded are guided very close to the actual point so that quicker loading is possible. This kind of loading head is frequently used for larger vessels.

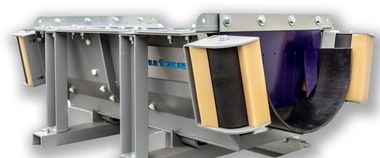

Loading heads are also used for bulk solids. If the loading head includes a cascade chute, the bulk solids “flow” gravimetrically in cones positioned laterally to each other. Finally the bulk material optionally falls into a chute with a small discharge radius of 1.5 m. Due to the transfer, the product has lost its impact force so that it arrives intact at the cargo hold. The head including discharge pipe can be turned up to 360 °. The discharge point should be kept very close above the material cone so as to minimize the dust load and the strain on the product. In order to counteract dust formation, it is possible to arrange vertically suspended cloths in the loading head opening.

The swivelling jet conveyor (360 °) is arranged at the loading pipe and throws the material horizontally over a distance of 10 m into the hatches. The vertical material velocity due to the gravity in the downcomer duct is horizontally deviated by a fast running belt conveyor (jet conveyor). The “discharge angle” can be adjusted. Hatch filling is maximal, even dead space is utilized this way. This loading alternative results in increased dust concentration. The material should be robust. Otherwise this method could lead to damage. The loading capacity is 2000 t/h.

SMB International GmbH, Quickborn (D),

Tel.: +49 4106 123880, www.smb-group.de