New standards for waste water decanters

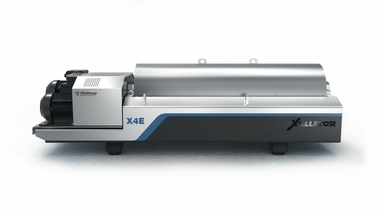

For Flottweg the top priority in the development of new products, is to continue to produce cutting edge energy efficient technology to maintain commitment and responsibility in preserving the natural resources. with its new decanter series Flottweg has made a quantum jump forward in both energy efficiency and processing performance. The optimal machine geometry of the new C-Series dramatically reduces electric power consumption. Efficient acceleration of the product in the feed zone combined with very specific internal scroll designs result in smaller installed horsepower requirements and lower overall power consumption of the motors (up to 20–30 %). In addition, current customers confirm the current configuration of the new C-Series maximizes both reliability and availability. Due to higher internal sedimentation volume, the capacity of a similar-sized machine is increased by 10–20 %, which ultimately results in lower investment costs since it is now possible to use a smaller machine for the same feed rate without suffering in processing performance. This helps the end user overcome capacity bottlenecks without sacrificing centrate or discharged cake quality. Since the Summer of 2008, more than 50 decanters of the new C-Series have been installed and run in different waste water applications including the dewatering and thickening of sewage sludges all with excellent results. The three available models C3E, C4E, and C5E (Fig.) cover processing ranges from 10-90 m3/hr (44–396 gpm).

Flottweg AG, Vilsbiburg (D), Tel.: +49 8741 301-0, www.flottweg.com