Zero emission heavy lifting on site: building a sustainable future

19.06.2024How Mammoet is innovating with zero-emission lifting and transport on site to help its customers reduce the carbon footprint of projects.

Mammoet Head of Sustainability Mathias Hoogstra

Mammoet Head of Sustainability Mathias Hoogstra

© Mammoet

“If you ask me what my main vision is, I want us to redefine the construction site – at least at small scale initially – where we have electric or hydrogen cars, electric cranes, electric trucks, and have all this equipment cross-link and charge each other,” said Mammoet Head of Sustainability Mathias Hoogstra. “An energy hub or energy balancing system would know where to direct power efficiently during a project. Equipment with the lowest energy would be fed by the equipment with the highest, or when required powered by additional external sources like hydrogen or bio-fuel generators. So, by design, we focus on exchanging energy as efficiently as possible and becoming zero-emission on site.”

Electric lifting

Electric lifting

© Mammoet

As the leader in heavy lifting and transportation, Mammoet sees sustainability as an important factor in the future of its industry. But given the huge loads it deals with; electrifying fleets of cranes and self-propelled trailers has for years felt like a pipe dream. Thanks to recent developments, the company can now credibly offer a whole project solution without tailpipe emissions – using equipment that it has already introduced to the market. The sustainable revolution is gathering pace in heavy industry, with large rewards on offer for those nimble enough to adapt.

Hoogstra continues: “You see now, in government legislation but also in the tendering process, solutions that are adhering to zero emissions score more points. In the past this was the case, but the delta is becoming more and more significant in the value chain. I wouldn’t say the whole flood wave is already there, but the first change is starting. If you want to be a leader in the market, in my opinion, you must ensure that you are leading this whole transition and are at the forefront for your customers.”

Rafael Martinez, Sales Manager for the civil sector at Mammoet

Rafael Martinez, Sales Manager for the civil sector at Mammoet

© Mammoet

Rafael Martinez, Sales Manager for the civil sector at Mammoet, has noticed the requirement for sustainable heavy lifting and transport growing over a number of years. “Low or zero-emission conditions are becoming more common these days,” he says. “There are sometimes very specific needs to drive down the carbon impact of projects, originated by local particularities or restrictions by public entities, like projects within congested urban environments, or environmentally protected areas. In Europe, this is something we are already seeing for tunnels."

Martinez is clear that we have reached the point where there is no turning back, and this is something that all companies must implement to succeed. “It can go faster in some sectors and countries, slower in others. Ultimately, we are all on this trajectory and all businesses must adapt and prepare. From a public opinion perspective, no-one will be able to sell the need for more diesel-powered machines on-site. It is starting to become more important, and in certain cases it becomes key. In fact, projects that generate significant carbon emissions find it more and more difficult to secure funding from large financial institutions”.

Towards zero emissions on site

Mammoet has been investing in ways to make its equipment less diesel-reliant, to give its customers greater choice when it comes to alternative power sources and help those customers to realize benefits such as smoother permitting procedures and a lower cost of borrowing. This has led to the scenario where, using existing equipment such as the electric SPMT transporter and the SK series of cranes, Mammoet can now offer a tailpipe emissions-free solution that could serve the entire site lifting and transport scope of a project. It’s a vision that, just a few years ago, would have seemed impossible, considering the long working hours required of Mammoet equipment.

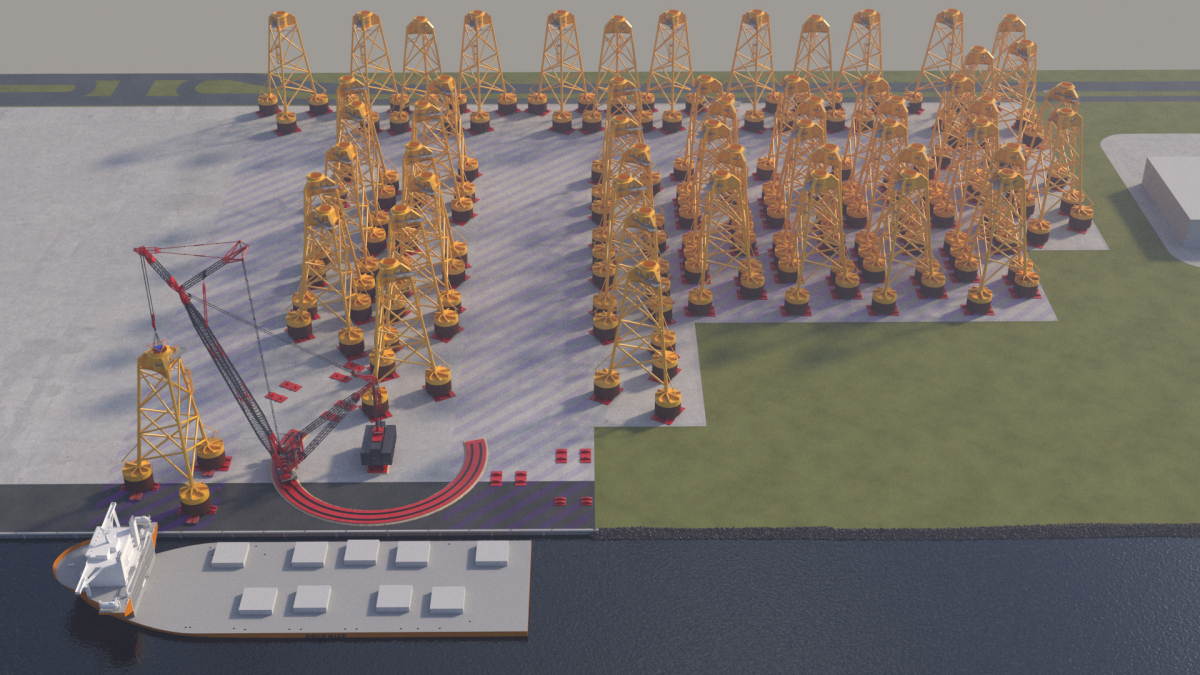

“I would say we are proving ourselves now,” says Hoogstra. “We were developing for specific markets; and from this we are now seeing that we can combine different solutions to make a whole project more sustainable, whatever the demand is. For example, we can now execute the marshalling and pre-assembly scopes of an offshore wind farm emissions-free. Our focus in the civil sector is to make sure that the movements of large items, such as viaducts and bridges, can be carried out with zero emissions using hydraulics that are powered by electricity. We installed a tunnel section recently in Belgium, of 850 tonnes, and did it fully electric. So, we can do it and can scale up fast to make sure we can do more”.

Mammoet’s Self-Propelled Modular Transporters (SPMTs) play a key part in many of its heavy lifting projects

Mammoet’s Self-Propelled Modular Transporters (SPMTs) play a key part in many of its heavy lifting projects

© Mammoet

Electric heavy transport

Mammoet’s Self-Propelled Modular Transporters (SPMTs) play a key part in many of its heavy lifting projects. Therefore, it made sense to look at how to electrify this key piece of equipment and offer a net zero heavy transport solution. Mammoet consulted with a trusted supplier to make an existing diesel power pack fully electric, and the first ePPU (electric Power Pack Unit) prototype was tested in Mammoet’s yard in Schiedam, the Netherlands.

When comparing capabilities, there is no significant difference between electric and diesel powered SPMTs. Both offer an industry-standard 40 tonnes per axle line. The power packs are the same size and fit in the same position on the transporters. They also operate in the same way, driving the hydraulics and powertrain. In terms of charging, the pack can go from 0 to 100 % in approximately five and a half hours, meaning it can charge overnight and be ready for action the next day – no significant change from the current scenario, where transporters generally lie idle at night.

Circular economy

Niek Bezuijen, Global Sustainability Advisor at Mammoet

Niek Bezuijen, Global Sustainability Advisor at Mammoet

© Mammoet

Innovations like the ePPU are helping to breathe new life into existing Mammoet equipment. Niek Bezuijen, Global Sustainability Advisor at Mammoet, says: “We nominated an old power pack to upgrade, which didn’t work as efficiently anymore. From a sustainability perspective, we thought: why don’t we retrofit it and make it electric because this results in a tailpipe zero-emission solution, and less waste? By reusing this equipment, we avoid the carbon impact of discarding it, the production cycle needed to create an all-new electric replacement, and – of course – the diesel emissions that the former equipment would have emitted when used”.

The goal of Mammoet’s work is to offer its customer a range of options for lowering the carbon impact of projects. So, it is looking into zero-emission operations, of all kinds. “A hydrogen power feasibility test was carried out by skidding a single electrical transformer. The hydraulic system uses a hydrogen generator to perform the skidding operation. This solution emits only water vapor. For practical reasons it is more favorable to do the operation electrically, via the grid, or with a battery,” said Bezuijen. “In remote areas, it is often still possible to bring a battery pack, because jacking and skidding at the lower tonnages doesn’t require much energy – this is what we discovered with the test using hydrogen, in fact. We performed the same test with the battery, and to put an electrical transformer in place we only used seven kilowatt-hours (kWh). To put that into perspective, a Tesla has around 60 or 70 kWh of battery, so we only used 10 % of that.”

Mammoet has engineered zero-emission offshore wind and onshore wind cranes, and the SK series of cranes has been a staple of its fleet for over a decade

Mammoet has engineered zero-emission offshore wind and onshore wind cranes, and the SK series of cranes has been a staple of its fleet for over a decade

© Mammoet

Net zero heavy lifting

Electric-powered cranes have been a focus for Mammoet for some time. The SK range is notable among ring cranes in that its hydraulics run from an electric motor, powered by a generator.

The SKs are great for construction projects that require a ring crane to be on site for a long period of time. But what about projects needing faster and shorter crane mobilization? To address this challenge, Mammoet recently developed a 100 t mobile crane that boasts a fully electric cab.

“This LTM 1095 crane was four years old,” says Bezuijen. “We decided to do a retrofit and use it as an opportunity to learn more about the electrification of our equipment. We also wanted to push the market for these types of cranes towards zero emission. The upper carrier (the cab) is fully electric. It has a 105kWh battery inside, so we can run basically a normal working day with it. We conducted some tests a couple of months ago and the crane is now ready to operate. The crane’s pre-existing engine was actually still in good condition, so we were able to use it to breathe new life into another crane in the fleet whose drivetrain was approaching end-of-life, and again reduce waste.”

Offsetting cost through energy efficiency

In terms of green energy adoption, one of the biggest barriers for these technologies is budget. This is something that Mammoet is mindful of and has considered in its vision for sustainability. Through innovation, it wants to support heavy industry to find energy savings to offset the potential costs of going green.

Hoogstra believes the transition to electric, hydrogen and biofuel powered equipment – and a change in mindset – hold the answer: “In previous years, we were looking to reduce usage of diesel on site. Now, we are taking a step further to monitor energy usage in an electric power environment and actively steer on efficient execution. We are conducting tests with our range of electric equipment to determine typical power usage per shift. This will help our customers to put appropriate and cost-effective electricity infrastructure in place, best suited to the project at hand.”

The only step remaining is to put these plans into action, says Hoogstra: “We are looking forward to speeding up the whole process based on the needs of our customers. As such, we are looking for participants among our customer base that want to work with us and take these steps together.”