Updates to Superior’s belt cleaners will reduce maintenance time

16.02.2023Superior Industries, Inc. made some tweaks to its Exterra® Conveyor Belt Cleaners, which will reduce time required to maintain the popular scraping systems.

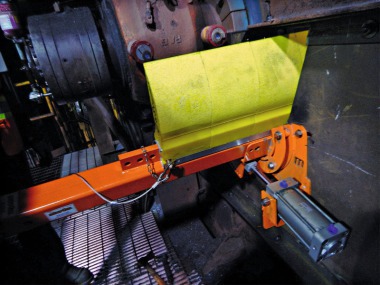

Superior Exterra® Conveyor Belt Cleaner

Superior Exterra® Conveyor Belt Cleaner

© Superior Industries

First, a new fast-acting click tensioner is available for the primary and secondary models. After installation, operators simply twist the tensioning unit for a prescribed number of times to set proper force. Click count instructions are conveniently labeled on the aluminum housing that protects the springs.

Second, Superior’s SFL scraper models are now manufactured with a special extruded tube. It’s designed to house the patented springs and seal them from fugitive material. The abbreviation SFL means “Set for Life”. Exterra Belt Cleaners with this SFL option require tensioning just once at the time of installation. Accurate tension is maintained automatically –with no required maintenance – for the entire life of the blade.

Third, Superior’s conveyor components engineers recently completed lab and field testing on a proprietary new mix of polyurethane, which is poured into molds to form the blades. This longer-lasting material is also more flexible, which endures beating from belt splices and wears more effectively. All blades are developed in-house by Superior.

There are several models of Exterra Belt Scrapers in both aggregate and mine duty constructions. Blade widths are available up to 2590 mm. Along with 250-tons of other products, Superior’s complete line of Exterra Belt Cleaners will be shown in Silver Lot booth #5006 at CONEXPO-CON/AGG 2023.