TOMRA Mining: enabling a sustainable starting point for the resources that will transform our world

02.07.2024The mining industry has an essential role to play in the modern world and its future. In its new brand video, TOMRA Mining outlines its mission to support the industry and enable a sustainable starting point for future businesses, industries and societies by harnessing its leading sorting technology and know-how to transform how natural resources are extracted and processed – Sorting tomorrow’s resources.

Chromium is mainly used to produce stainless steels and to refine surfaces by chrome plating. Due to its high melting point, chromite is used to produce highly refractory chromium and chromium magnesite bricks

Chromium is mainly used to produce stainless steels and to refine surfaces by chrome plating. Due to its high melting point, chromite is used to produce highly refractory chromium and chromium magnesite bricks

© Tomra

Minerals and metals are essential enablers of almost every aspect of our daily life – from the copper in our lightbulbs and electrical wiring to the steel and aluminium for our vehicles and machines; from the raw materials to build our houses and roads to the phosphates used for fertilizers in agriculture. The technology that has become an integral part of our daily lives depends on the rare earth elements, lithium and tungsten in electronics, batteries, and all the devices that have become indispensable, such as our smartphones and laptops.

Very importantly, minerals are critical to the energy transition because clean energy technologies require much bigger quantities than fossil-based ones. According to an IEA report, “a typical electric car requires six times the mineral inputs of a conventional car and an onshore wind plant requires nine times more mineral resources than a gas-fired plant.” These technologies are driving an increase in the demand for minerals such as lithium, nickel, cobalt, manganese and rare earths – a trend that is accelerating as the energy transition gathers pace. Recycling rates for these materials are low and even if they were to increase, recycling alone would not be able to meet the demand, so mining will continue to be the main supplier of these resources. Mining efficiently and sustainably is key.

Albert du Preez, Head of TOMRA Mining

Albert du Preez, Head of TOMRA Mining

© Tomra

“Mining is an essential industry enabling our modern world and faces the challenge of meeting the huge rise in demand driven by the energy transition with sustainably mined resources. As we look to the future, it’s clear that what we mine and how we process it must be transformed,” states Albert du Preez, Head of TOMRA Mining.

Meeting the surging demand for minerals with financially and environmentally sustainable mining

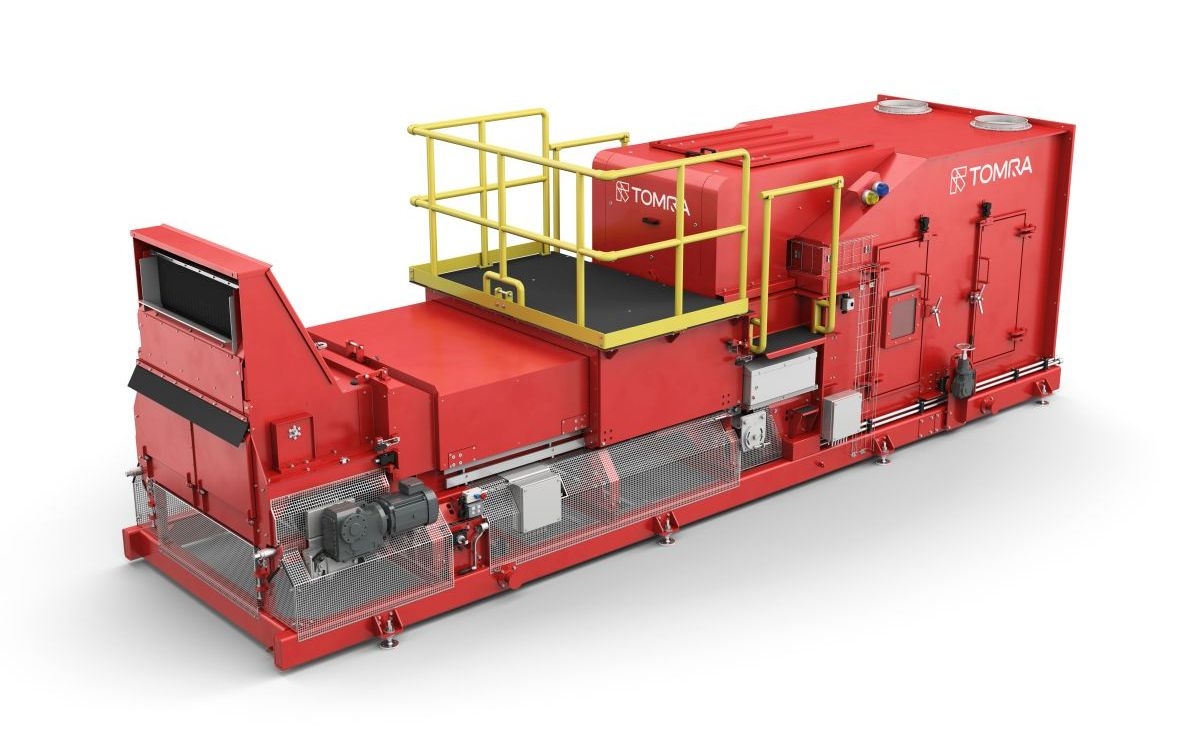

The mining industry faces the challenge of supplying the vast amounts of minerals that will be required to decarbonize the global economy while reducing its environmental footprint and ensuring its profitability. TOMRA Mining is already helping mining operations across the world maximize resource recoveries and minimize their impact on the environment with its sensor-based sorting technologies. It brings to bear its extensive knowledge of the different mineral resources and experience in developing industry-leading sorting technologies.

© Tomra

© Tomra

“At TOMRA Mining, we truly believe that our technology and innovation can transform the mining business and help future-proof the industry,” continues Albert du Preez.

TOMRA’s sensor-based sorting solutions can be used to eliminate waste effectively in the early stages of the process, so that less barren or low-grade ore is processed, with consequent cost savings. These technologies significantly reduce the amount of energy and water used compared to traditional methods like DMS (Dense Media Separation), while maximizing the efficiency and recovery of valuable ores. In addition, its sensor-based sorting technologies enable mining operations to extract value from existing stockpiles of contaminated rock as well as turning waste into certified clean aggregates, generating a new income stream. The benefits are efficient mining, lower costs, improved profitability and a reduced impact on the environment.

Kai Bartram, Global Sales Director at TOMRA Mining

Kai Bartram, Global Sales Director at TOMRA Mining

© Tomra

“As mining operations strive to meet the demand and ensure their profitability, the mining process will become more and more automated,” explains Kai Bartram, Global Sales Director at TOMRA Mining. “At TOMRA we have the knowledge to advise them on how to integrate our sorting technologies into their process to optimize its efficiency and reduce their running costs. We have built a strong track record in helping mines maximize their resource recovery while reducing their environmental footprint and ensuring their profitability, and we believe that we have a key role to play in the mining industry’s shift towards automation.”

“There is a solid business case for TOMRA sorters in the mining industry: they have proved to pay for themselves quickly through the increased efficiency and reduced costs they deliver. The environmental advantage is an important added value, as mines are increasingly under pressure to operate sustainably,“ adds du Preez.

Future-proofing mining: digitalization and Artificial Intelligence

Digital technologies are transforming mining, helping mines run their operations more efficiently and profitably. Digitalization has opened up opportunities with innovations such as the TOMRA Insight, the cloud-based data platform that turns TOMRA sorters into connected devices that collect valuable performance metrics from the materials they process. This enables mines to continuously monitor and optimize their sorting line’s output quality, as well as provide useful insights into their operation.

Artificial Intelligence (AI) has been operating in TOMRA’s sensor-based sorting solutions for many years, automating the process and improving the accuracy and efficiency of the sorters, playing an increasingly important role as the technology has developed. Most recently, TOMRA has opened a new era of sorting with its Deep Learning (DL) OBTAIN™ solution, which brings single-particle precision to high-throughput particle sorting. This technology also unlocks value for the mining operation with a wealth of extremely detailed and accurate data for better-informed decision-making.

“At TOMRA we are constantly exploring the potential of AI and DL to provide solutions for sorting applications that were previously impossible for sensor-based sorters or to improve further our existing technology to provide better customer support, deeper analysis of the sorted material, or data for predictive maintenance, for example,” says Stefan Jürgensen, Software Team Leader TOMRA Mining and responsible of the latest company launch OBTAINTM.

Enabling a sustainable starting point for the resources that will transform our world

As the mining industry faces the daunting challenge of supplying the vast amounts of metals and minerals the modern world will require, TOMRA Mining is ready to support it with its advanced sorting knowledge and technology.

“We see ourselves as the movers who lead the way with our resource knowledge and leading sorting technologies, the makers who transform how natural resources are extracted and mined sustainably, and the caretakers of our natural resources who work to maximize recovery and minimize environmental impact with our customers and partners. We believe that TOMRA Mining has a role to play in the future of mining, and have set ourselves a clear mission: to enable a sustainable starting point for the resources that will transform future businesses, industries and societies. We sort tomorrow’s resources,” concludes Albert du Preez.