TAKRAF Group awarded new contract for conveying system for Collahuasi mine in Chile

13.02.2025TAKRAF Group (TAKRAF) announced the award to engineer and supply the conveying system (CV-8001, CV-8002 and CV-8003) for Minera Collahuasi’s Ujina growth project in Chile. The main objective of the Ujina growth project is to increase the capacity of the concentrator plant.

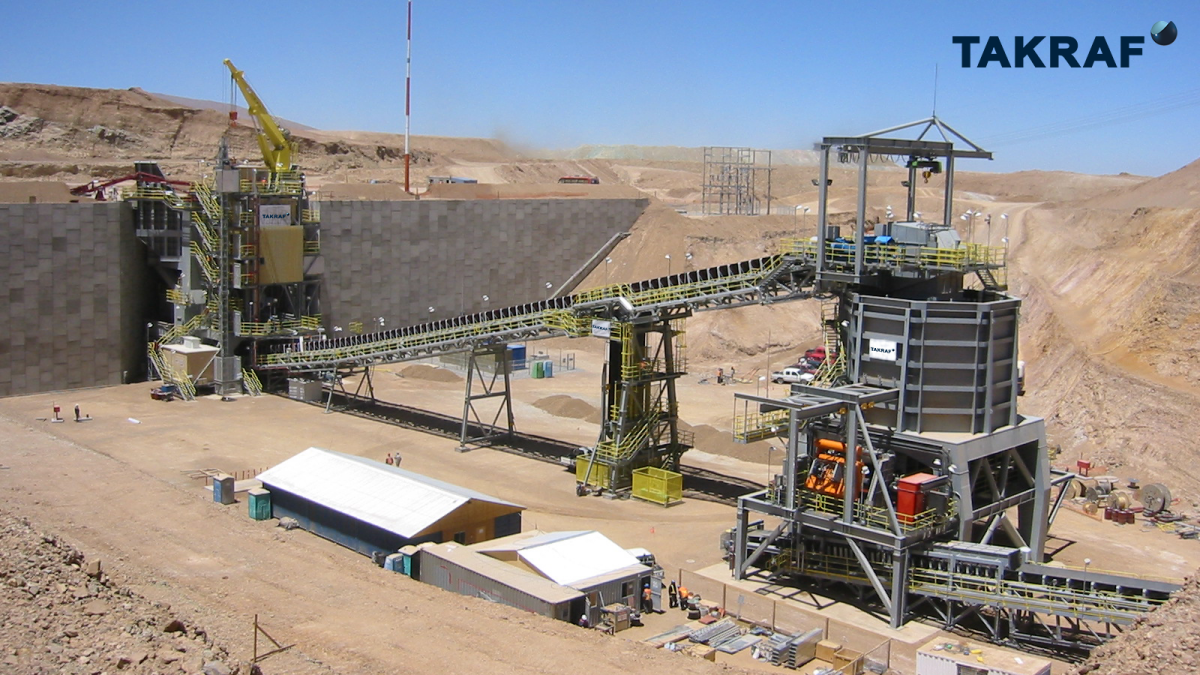

From left to right: TAKRAF Primary Crushing Station and TAKRAF Discharge Conveyor to transport the crushed material to a TAKRAF Transfer Silo equipped with a belt feeder

From left to right: TAKRAF Primary Crushing Station and TAKRAF Discharge Conveyor to transport the crushed material to a TAKRAF Transfer Silo equipped with a belt feeder

© TAKRAF

The Collahuasi mine is located at an impressive elevation of 4535 m above sea level and has been in operation since 2003. It is one of the largest copper producers in the world, one of the largest copper deposits globally.

TAKRAF’s scope of supply: Conveyor system (CV-8001, CV-8002, CV-8003) to connect an existing, relocated crushing station to an existing conveyor system

TAKRAF’s scope of supply: Conveyor system (CV-8001, CV-8002, CV-8003) to connect an existing, relocated crushing station to an existing conveyor system

© TAKRAF

TAKRAF’s scope of supply for this brownfield project comprises the design and supply of three advanced conveyors. This system will seamlessly connect a relocated crushing station to the mine’s existing conveyor network, ensuring efficient material handling under challenging operational conditions.

TAKRAF Crushing Station and TAKRAF Conveyor for the discharged material delivered in 2003

TAKRAF Crushing Station and TAKRAF Conveyor for the discharged material delivered in 2003

© TAKRAF

“We are particularly proud and would like to highlight the client’s continued interest in TAKRAF equipment, 20 years after the initial supply. This is a testament to the quality and excellence of our colleagues in designing and delivering exceptional equipment that ensures reliable operation, a fundamental requirement for any mining equipment,” says Andres Costa, Managing Director of TAKRAF Chile and Peru.

TAKRAF extends its gratitude to the client for their trust and to its teams in Germany and Chile for their exceptional collaboration and technical expertise. This achievement reaffirms TAKRAF’s position as a leading provider of innovative solutions in mining and material handling.