Swiss Eberhard Group upgrades sorting line with ZenRobotics 4.0

21.06.2024The Eberhard Group – a Swiss family-owned waste management company and long-term customer of ZenRobotics® – has recently upgraded its robotic sorting line with the latest ZenRobotics 4.0 System to further optimise its resource recovery processes.

Heavy Picker Sorting at Eberhard

Heavy Picker Sorting at Eberhard

© ZenRobotics

Boasting a robotic sorting line comprising six ZenRobotics Heavy Picker robots, initially installed in 2021, the Eberhard facility in Switzerland efficiently processes up to 200 t of mixed demolition waste per hour, recovering valuable high-purity materials. These recovered materials are transformed into Zirkulit® concrete, a circular building material that rivals its virgin counterparts in both mechanical strength and environmental sustainability. Zirkulit® concrete stores up to 10 kg of CO2 emissions per cubic metre and uses almost 7 % less cement, contributing to a greener construction industry.

The ZenRobotics 4.0 upgrade introduces several enhancements designed to further elevate operational efficiency and material recovery rates at Eberhard's facility. Each Heavy Picker now benefits from an individual recognition system and ZenBrAIn interface, empowering the robots with enhanced intelligence, speed, and adaptability.

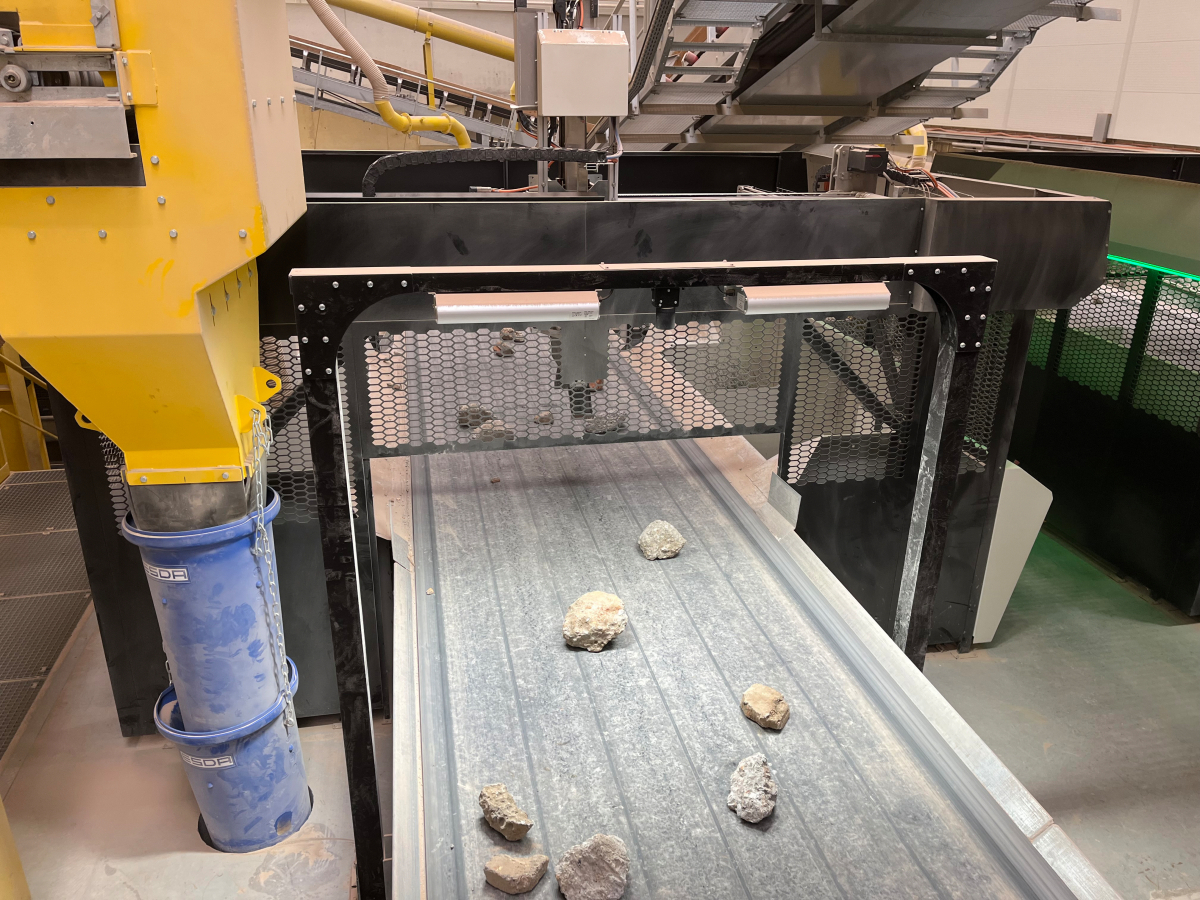

New ZenRobotics 4.0 Recognition System at Eberhard

New ZenRobotics 4.0 Recognition System at Eberhard

© ZenRobotics

One of the key advancements of ZenRobotics 4.0 is its improved material recognition capabilities and gripping precision, resulting in higher yields and purity levels of the processed materials. The new software facilitates better decision-making and enables the robots to successfully identify and pick desired objects from the conveyor belt, even amidst challenging conditions. Additionally, the system's compact sensor recognition design minimises space requirements and simplifies maintenance, offering Eberhard greater flexibility for future expansion.

Eberhard also benefits from ZenBrAIn's extensive global training database, encompassing over 500 material categories. This resource reduces the need for localised fraction training, streamlining system commissioning and enhancing overall operational efficiency.

"We are thrilled to enhance our waste sorting capabilities with ZenRobotics 4.0," remarked Jonas Inderbitzin, Plant Manager at Eberhard. "This upgrade not only boosts our operational efficiency and material recovery rates but also aligns perfectly with our commitment to sustainable waste management practices. Upgrading to ZenRobotics 4.0 means that our Heavy Pickers can now lift up to 40 kg heavy chunks of material, as well as being smarter than ever before."

Six Heavy Pickers upgraded to 4.0 at Eberhard in Switzerland

Six Heavy Pickers upgraded to 4.0 at Eberhard in Switzerland

© ZenRobotics

In addition to the technological advancements, the ZenRobotics 4.0 upgrade includes a new user-friendly digital interface and online reporting tool, empowering Eberhard with real-time insights into material composition and system performance. The company can now easily optimise their sorting tasks and purities of recovered materials at the touch of a button.

With the deployment of the ZenRobotics 4.0 System, Eberhard reaffirms its position at the forefront of innovation in waste management, driving towards a more sustainable future.