Swedish Steel Prize 2019 finalists symbolize 20 years of innovative engineering

12.11.2019

The four finalists for the Swedish Steel Prize 2019 are announced, from left to right: Austin Engineering’s lightweight modular excavator bucket, Kampag’s productivity boosting soya harvester, Roofit.solar’s environmentally friendly solar panel integrated roof structures, and Shape Corporation’s high strength manufacturing process for 3D tubing

The four finalists for the Swedish Steel Prize 2019 are announced, from left to right: Austin Engineering’s lightweight modular excavator bucket, Kampag’s productivity boosting soya harvester, Roofit.solar’s environmentally friendly solar panel integrated roof structures, and Shape Corporation’s high strength manufacturing process for 3D tubing

© SSAB

The finalists for the Swedish Steel Prize 2019 have been named and include four revolutionary design concepts that fully utilize the characteristics of premium steel within SSAB’s product range. The winner will be announced at a ceremony in Stockholm on November 14 that celebrates the 20th anniversary of the Swedish Steel Prize.

“For the 20th anniversary of the Swedish Steel Prize, the four finalists we have nominated each have a strong connection to a stronger, lighter and more sustainable future. They all show that with new perspectives and innovative thinking comes possibilities to continue moving forward, pushing not only their own industry but also society as a whole,” says Eva Petursson, chair of the Swedish Steel Prize jury and head of SSAB’s research and innovation. The four finalists and jury motivations are:

Austin Engineering, Australia

Lightweight modular excavator bucket from Austin Engineering, Australia

Lightweight modular excavator bucket from Austin Engineering, Australia

© SSAB / Austin Engineering

Austin Engineering has taken a significant leap in innovation for the design and maintenance of excavator buckets. With a modular approach, they have developed an innovative concept that combines low weight with optimal use of the complete product before scrapping. The solution utilizes the characteristics of high strength and wear resistant steel and has extremely low barriers for implementation. This clearly opens up for further bucket design innovations.

Kampag, Brazil

Soya harvester from Kampag, Brazil

Soya harvester from Kampag, Brazil

© SSAB / Kampag

Kampag has managed to increase soya yields by focusing its harvester design on the gentler handling of the crop. A unique feeding modulus unit shows less damage to the harvested bean and also increases machine availability in conditions with high humidity. Additional productivity and sustainability benefits have been realized when upgrading to high strength and wear resistant steel including, increased service life, reduced weight and more lean production as well as maintenance processes with energy savings.

Roofit.solar, Estonia

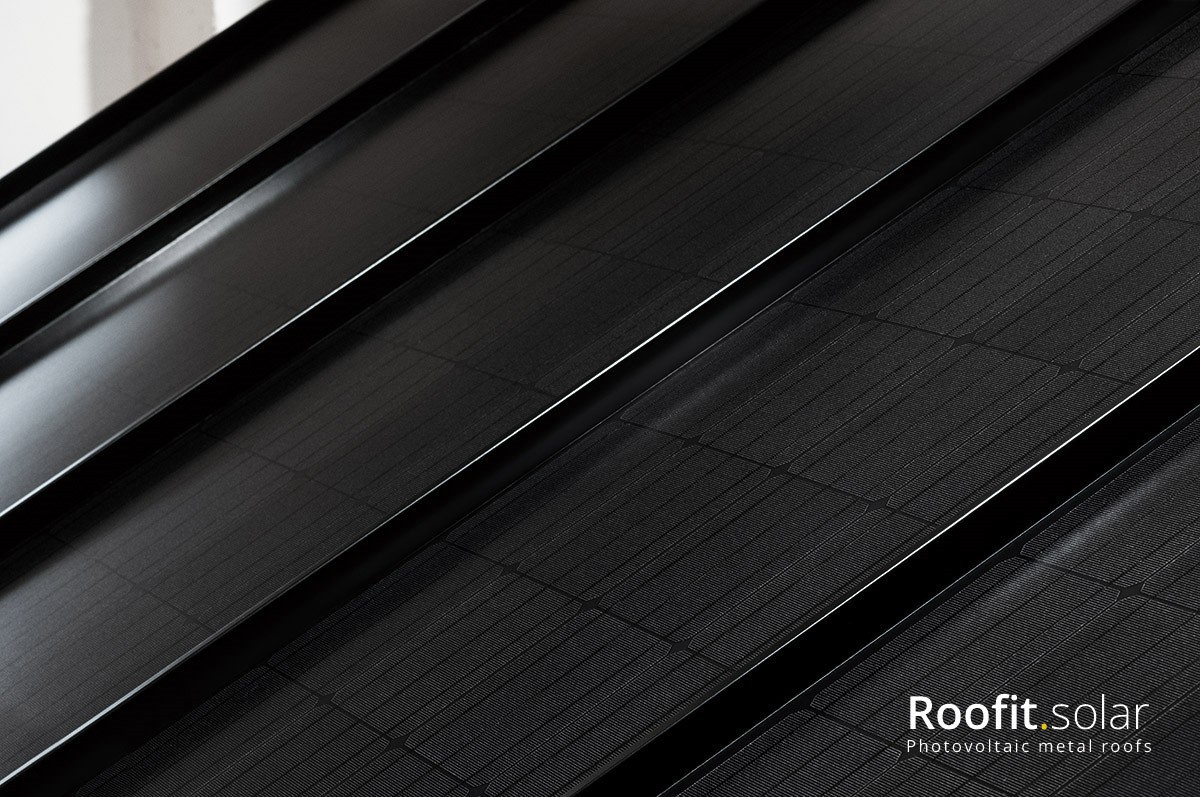

Solar panel integrated roof structures from Roofit.solar, Estonia

Solar panel integrated roof structures from Roofit.solar, Estonia

© SSAB / Roofit.solar

Roofit.solar makes metal solar roofs that produce electricity. The product successfully combines an effective solar panel solution with an architecturally attractive environment friendly steel roof that also enables historical building restorations to benefit from new technological advancements. Using a color coating based on rapeseed oil, it has been possible to push production technology limits and the result shows excellent robust adhesion between the layers of the solar roof panel.

Shape Corporation, USA

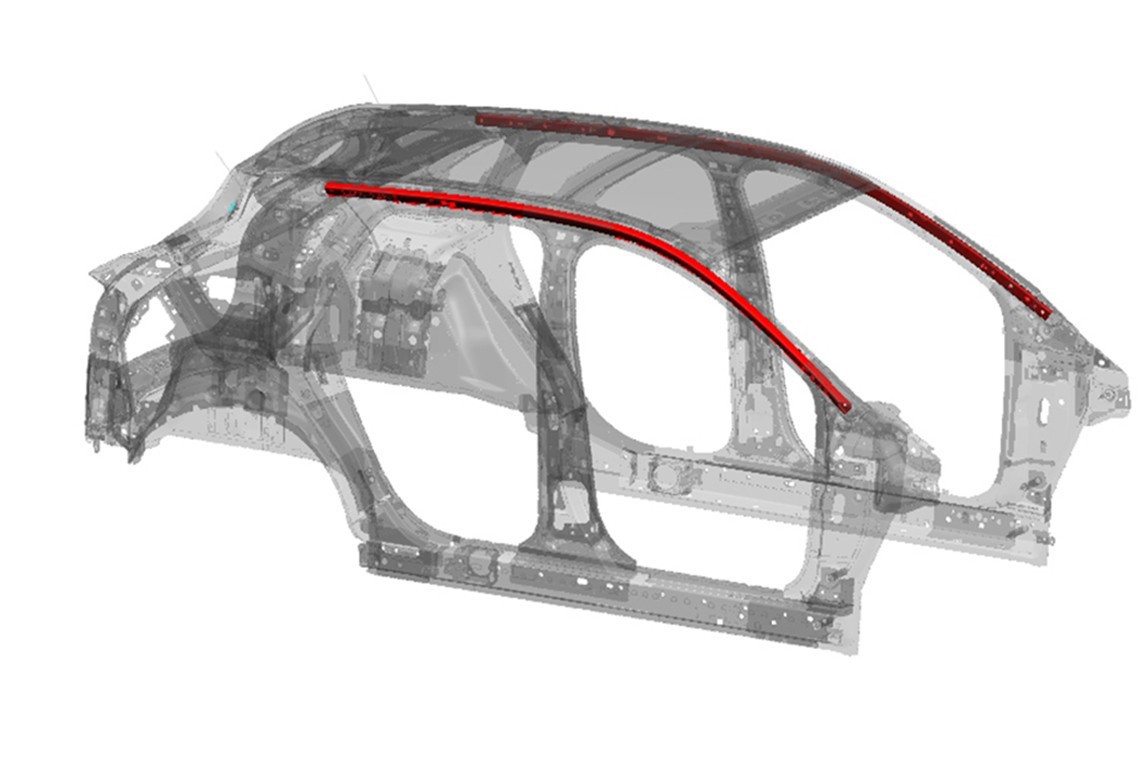

High strength manufacturing process for 3D tubing from Shape Corporation, USA

High strength manufacturing process for 3D tubing from Shape Corporation, USA

© SSAB / Shape Corporation

Shape has developed a cost effective and robust manufacturing process for 3D shaped tubes that makes it possible to utilize cold forming steels with the highest strength levels currently in existence. With this technology, a unique lightweight solution for A-pillar and roof rail tubes, with minimal section size, is now ready for implementation by a major automotive manufacturer during 2020. This pioneering innovation will challenge other lightweight materials with a much more sustainable steel solution that allows for circular material flows.