SpectraFlow Analytics received second order for a crossbelt analyser for iron ore quality monitoring from Vale S.S., Brazil

27.02.2024Vale S.A. Brazil ordered the second SpectraFlow Crossbelt Analyzer for quality monitoring of its iron ore dispatch terminal of Ponta da Madeira (TMPM), Maranhão/Brazil. This is the second order of VALE S.A. and the third order of a minerals Crossbelt Analyzer in South America.

After the very successful installation of a SpectraFlow Crossbelt Analyzer for the same application in the Terminal Ilha Guaíba in Rio de Janeiro, this is now second installation of a SpectraFlow Analyzer within VALE to enhance the ship loading with real-time data.

© SpectraFlow Analytics

© SpectraFlow Analytics

SpectraFlow is already installed in the cement, iron ore, gold, platinum, copper, potash, bauxite and recycling industries, while expanding the applications continuously within the individual industries and into new fields.

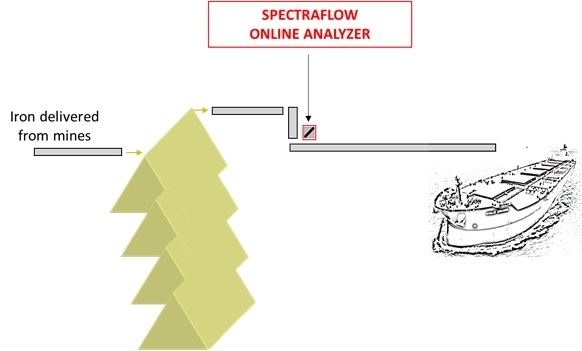

SpectraFlow installation for quality monitoring

The SpectraFlow Crossbelt Analyzer is an online analyzer to be able to measure raw materials on belt conveyors in a very high frequency. As raw materials from the mine are processed through a crusher and blended various times, the raw material on the conveyor belt is statistically homogeneous and therefore the analytical results of the SpectraFlow Crossbelt Analyzer are very accurate. Based on these accurate, high frequent results the feed from the blending yards onto the ships can exactly be monitored. Beside the exact monitoring of the quality of the ship load also the quality of the supplied ore from the various mines can be monitored.

© SpectraFlow Analytics

© SpectraFlow Analytics

By using SpectraFlow an optimization of the raw material handling will be achieved.

Summarized benefits are:

- No need of sampling. Sampling from conveyor belts is unrepresentative and slow for process optimization. Additionally sampling is very work intensive regarding operation and maintenance.

- The analyzer will deliver accurate results of the total ship load quality. Beside the mineral elemental and mineral content also moisture is measured.

- The data can be used to track the raw material quality from the different mines.

- Due to high frequent measurements further control strategies can be implemented.

This SpectraFlow order is the 20th order for the minerals industry and the 4th order in South America. This order raises the installed based in Brazil to 3 analyzers (2 Crossbelt, 1 Airslide) and worldwide to 80 analyzers (43 Crossbelt & 37 Airslide).