Plant expansion includes training facility with life-sized conveyor models

27.06.2018

The Tata Steel facility in Kalinga Nagar/Odisha

The Tata Steel facility in Kalinga Nagar/Odisha

Source: Martin Engineering

Martin engineering has helped one of the largest steel manufacturers in the world to train new staff on conveyor operations and safety at one of the company’s newest facilities. After expanding the existing plant, Tata Steel Limited constructed a dedicated training facility and invited Martin Engineering® to spearhead the equipment and safety curriculum using its popular Foundations reference book series, which focuses on productivity and safety. The company also installed full-sized conveyor sections so that trainees could experience each component in a controlled learning atmosphere. The program is helping Tata Steel develop a large staff of knowledgeable new technicians and managers with the skills required to operate safely in a contemporary bulk handling environment. “The training center was newly established for our fresh hires,” said Rutu Ranjan Padhi, Head of Training & Development for Tata Steel. “We were confident the trainees would benefit greatly from the courses and life-sized models.”

The facility was purpose-built for training on operations and safety

The facility was purpose-built for training on operations and safety

Source: Martin Engineering

Located near the East Central coast of India in the State of Odisha, Tata Steel, one of the country's largest steel producers, expanded upon the plant originally envisaged in 2004. In 2015, it increased the facility’s production capacity to 3 million m/t (5.5 mil. s/t) annually, taking the company's total domestic steel output to 13 million m/t (19.5 mil. s/t) per year.

The expansion was also intended to benefit the largely underdeveloped Kalinga Nagar inland tribal area that was in need of employment, skills training and resources. Considered one of the fastest growing economies in the country, Odisha is attractive to both domestic and foreign investment, with growing urban areas along its extensive coastline. However, due to its relative isolation, the inland population had not yet caught up to the rapidly advancing urban culture.

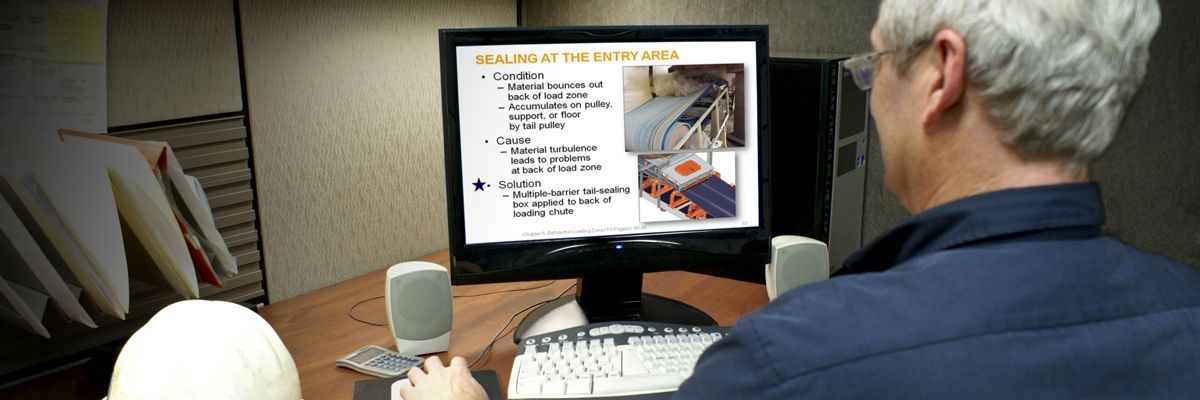

Visual aids are an essential part of the learning process

Visual aids are an essential part of the learning process

Source: Martin Engineering

Dedicated to the principals of a safe workplace, the collaborative effort offers local hires structured and intensive training on bulk material handling, since few had access to vocational education and many had never seen a conveyor before.

Having provided advanced training at Tata’s Jamshedpur facility in 2015, the steel producer partnered with Martin Engineering to deliver a complete course, from basic conveyor components and operation to advanced engineering concepts. With a curriculum that covers potential risks, operational skills and best practices, the trainers emphasized the Martin Engineering core principal of “Production Done Safely.”

Displays and literature helped trainees acquire hands-on experience and contribute to a robust safety culture

Displays and literature helped trainees acquire hands-on experience and contribute to a robust safety culture

Source: Martin Engineering

For over two decades, Martin Engineering has utilized its 500+ page reference book, now in its 4th edition, to train employees and customers on the function, maintenance and safe operation of conveyor systems. Introduced in 2016, the first edition of the company’s Safety Book – also 500+ pages – presents more detailed concepts specifically on safety regulations and procedures. The entire program is designed to maximize operators’ understanding of current equipment and technologies, help improve system performance, reduce downtime and minimize hazards.

Along with the classroom experience, the new Kalinga Nagar training facility also included conveyor sections comprised of hundreds of components, such as tail pulley, chute, impact cradles, idlers, belt aligners, head pulley and cleaners, all representing real-world operations. With the ability to examine and train on full-scale equipment, the new employees learned how to identify issues, maintain components and replace equipment from a place of knowledge and safety.

“With the training equipment, we are able to show components of the conveyor belt along with many accessories such as different types of scrapers, belt trackers, air cannons, etc.” said Padhi. “It is an extremely important part of the process.” The goal is a staff that is well-trained and competent in conveyor functions, building a working knowledge of the equipment to ensure safe, productive operation.

20 000+ copies of the Martin reference books are in circulation around the world, most downloaded as free PDFs

20 000+ copies of the Martin reference books are in circulation around the world, most downloaded as free PDFs

Source: Martin Engineering

Result

Despite the trainees’ lack of prior training and experience, program organizers have been able to graduate 152 service technicians and 34 company officers to date, helping Tata Steel ensure the safest and most productive conveyor operations possible.