NORD at the IFAT 2022: Drive systems for wastewater handling

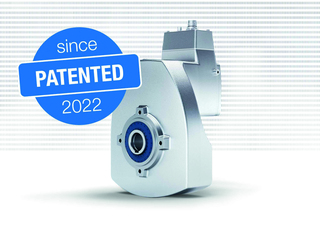

17.05.2022From 30 May to 3 June 2022, the IFAT will take place in Munich. NORD DRIVESYSTEMS, too, will be present again this year after the pandemic-induced break, presenting innovative and intelligent drive technology for water, wastewater, waste and raw materials management at the world's leading trade fair. Among other things, the spotlight will be on the patented wash-down-capable DuoDrive geared motor and the SAFOMI-IEC adapter for optimised use of MAXXDRIVE® industrial gear units in mixing and agitation processes.

By installing the motor and the gear unit in one single housing, the patented DuoDrive is very lightweight and compact, coupled with very high power density

By installing the motor and the gear unit in one single housing, the patented DuoDrive is very lightweight and compact, coupled with very high power density

© NORD DRIVESYSTEMS

Transport and distribution of drinking water, conveying of wastewater, circulation of activated sludge or comparable process engineering applications: Pump systems, as well as mixers and agitators, are elemental components in process and wastewater and engineering systems, and ensure the smooth operation of sewage treatment plants, waterworks systems and production plants. They often have to circulate large volumes of liquid or highly viscous substances. Therefore, availability, reliability and a long service life are the top priorities. As a system supplier, NORD offers fully matched drive systems consisting of gear unit, motor and frequency inverter that are tailored to the respective requirements of the customer application. NORD drive solutions can be networked, operate autonomously, and their functions and performance are scalable.

The new DuoDrive: Gear unit and motor combined

The innovative and patented DuoDrive geared motor in robust and hygienic wash-down design integrates a high-efficiency IE5+ synchronous motor into a single-stage helical gear unit. This not only guarantees a compact size and minimal noise emissions but also high power density and overall high system efficiency. As a system, the very compact DuoDrive concept achieves a significantly higher energy efficiency than the already proven drive systems with IE5+ synchronous motor and bevel gear unit. At up to 92 %, DuoDrive currently offers the highest system efficiency on the market in this power class, and achieves very high efficiency in the partial load range. Together with its simple plug-and-play commissioning, the complete DuoDrive solution results in a significant reduction in Total Cost of Ownership (TCO) compared to other drive systems.

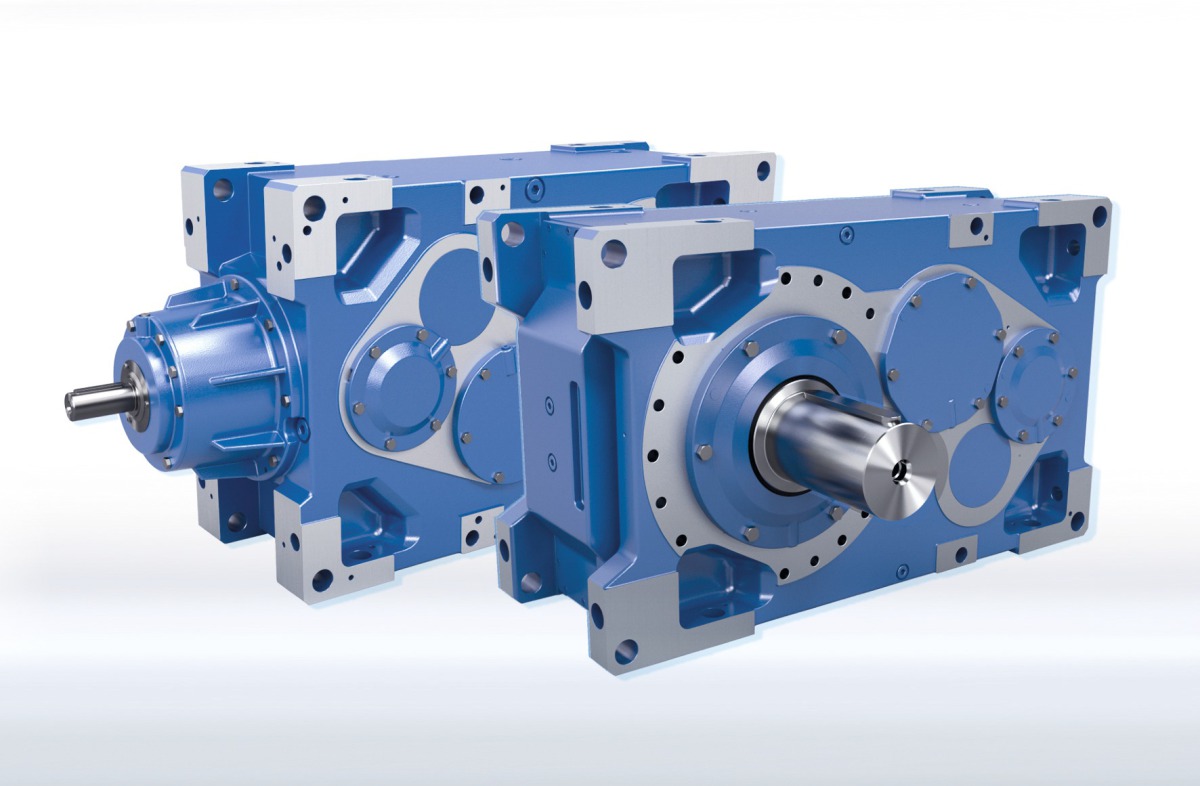

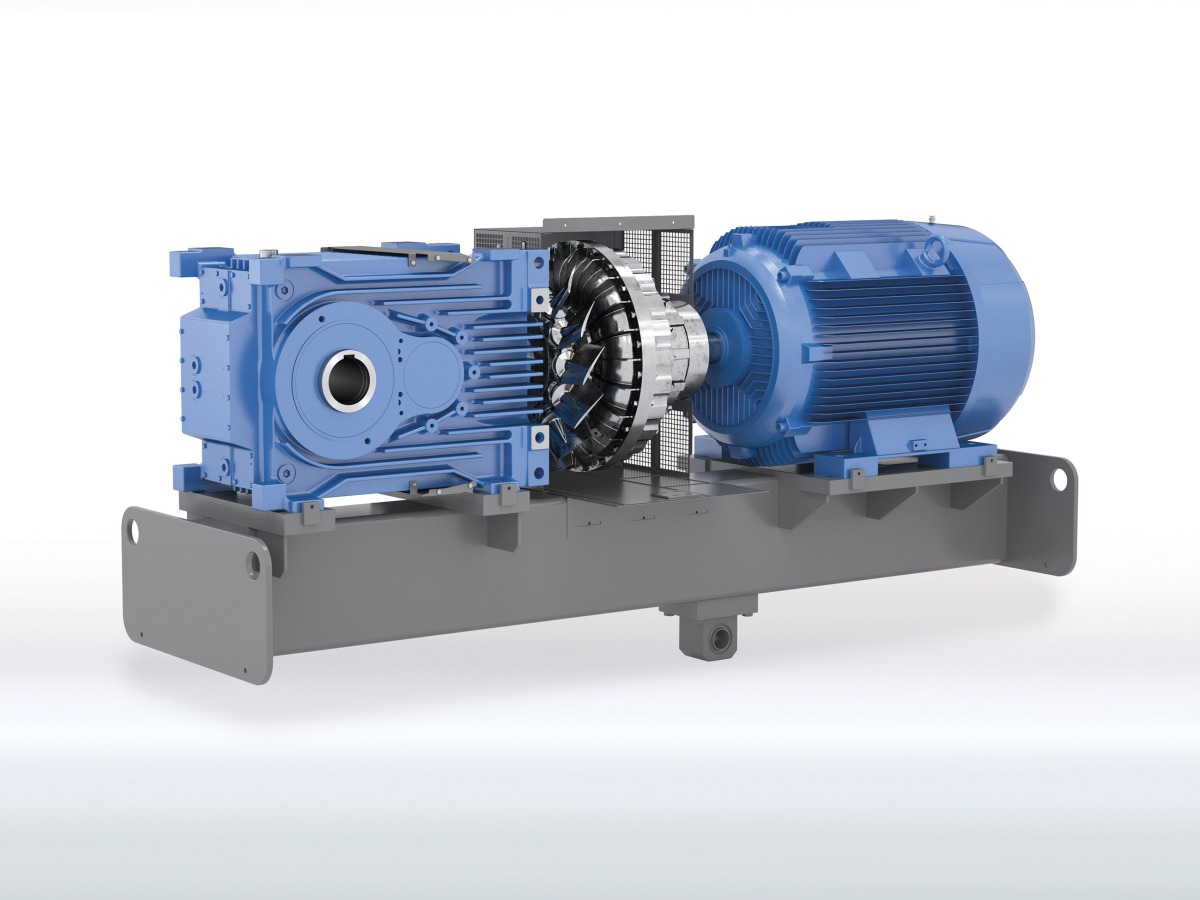

SAFOMI-IEC adapter for MAXXDRIVE® industrial gear units from NORD DRIVESYSTEMS combined with a drive motor: less components, increased operational reliability

SAFOMI-IEC adapter for MAXXDRIVE® industrial gear units from NORD DRIVESYSTEMS combined with a drive motor: less components, increased operational reliability

© NORD DRIVESYSTEMS

SAFOMI-IEC adapter for agitators

NORD has developed the SAFOMI-IEC adapter specifically for agitators. If it is used for an agitator drive instead of a standard IEC adapter, a higher operational reliability and less maintenance will be achieved. However, its main advantage is an integrated oil expansion volume. Therefore, oil tanks and hoses as well as the radial shaft seal, which is subject to leakage and wear between gear unit and IEC cylinder, are not required. SAFOMI is available for MAXXDRIVE® parallel gear units in sizes 7 to 11 and covers maximum output torques from 25 to 75 kNm. The compact combination of a MAXXDRIVE® industrial gear unit, the SAFOMI-IEC adapter and a drive motor is the best choice for mixer and agitator applications to reduce wearing parts and attached components.

Hall A1, stand 314