New products from Superior Industries at CONEXPO-CON/AGG 2023

17.03.2023Superior adds two new cone models to crushing portfolio

New Superior crushers Dakota™ Cone and Endeavor™ Cone

New Superior crushers Dakota™ Cone and Endeavor™ Cone

© Superior Industries

Superior Industries debuted two new cone crushing models at CONEXPO-CON/AGG 2023. With the well-established Patriot® Cone Crusher, Superior now manufactures a Dakota™ Cone and Endeavor™ Cone. Each model has its own set of unique features, so aggregate producers get premium performance in a wide variety of applications. “Instead of having to make a choice, we want to offer our customers a solution,” says Jason Adams, president of Superior. “From one manufacturer, aggregate producers now have three cone crusher options and can pick what’s right for their application, marketplace, and crews.”

The new Dakota Cone Crusher is a roller bearing design, which typically offers the most efficient use of horsepower per ton of crushed rock. Some features include a steel threaded bowl, one piece cast mainframe, a tramp relief system with fewer accumulators, and a hydraulically operated ant-spin system, which eliminates labor-intensive installation of individual gears. Superior’s new Endeavor Cone is a spider bushing design. Historically, spider bushing cones accept the largest range of feed sizes and are known for simple operation and favorable maintenance. Other features include the strongest shaft style our industry has designed to date, which is supported on a cast top and cast bottom shell; top access chamber, which is safer to access and more simple to maintain; and multiple strokes and liner configurations for increased application flexibility.

With these two additions, Superior’s cone crushing products are capable of high performance in primary, secondary or tertiary applications and within portable or stationary settings. Maximum feed opening is up to 450 mm with horsepower ranging from 200-800 (150-600) kW.

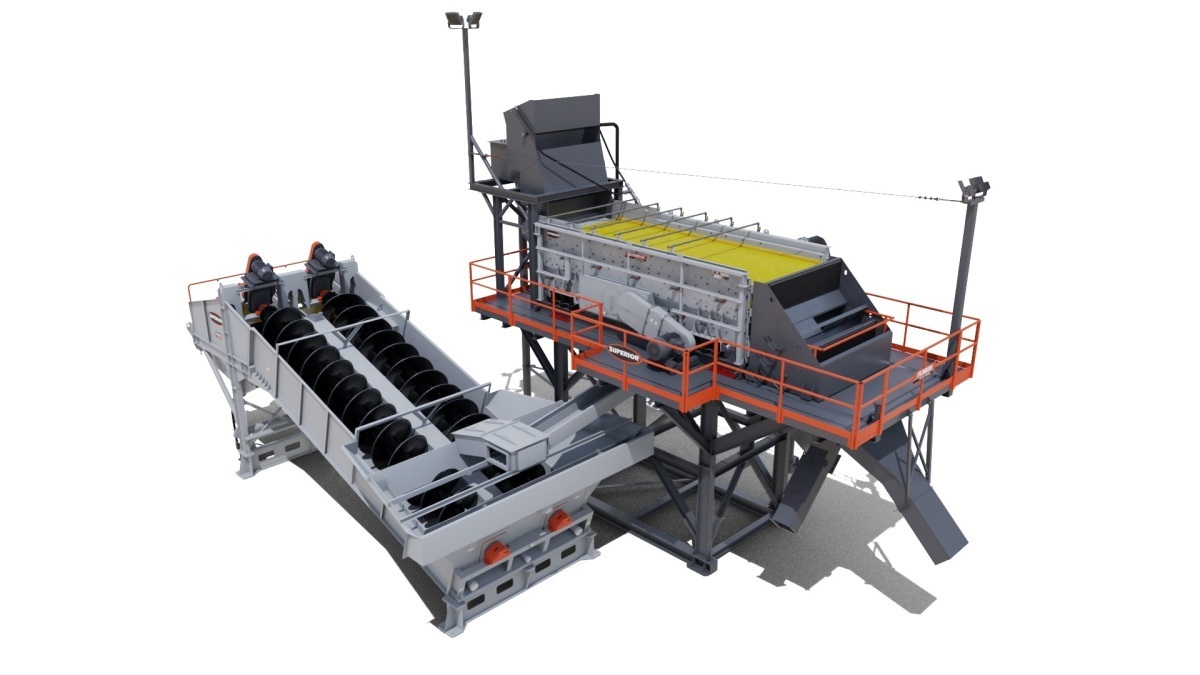

Superior installs modular screen-wash platform at CONEXPO

Fusion® Platform shown at CONEXPO-CON/AGG included an 8×20 Guardian® Horizontal Wet Screen with an integrated Twin Aggredry® Washer, and freshwater distribution supply hub

Fusion® Platform shown at CONEXPO-CON/AGG included an 8×20 Guardian® Horizontal Wet Screen with an integrated Twin Aggredry® Washer, and freshwater distribution supply hub

© Superior Industries

Superior Industries installed one of its pre-engineered modular plants at CONEXPO-CON/AGG 2023. Known as Fusion® Platforms, these customizable crushing, screening and washing platforms are recognized for design scalability, straightforward installations, and improved access for maintenance. The particular package shown at CONEXPO-CON/AGG included an 8×20 Guardian® Horizontal Wet Screen with an integrated Twin Aggredry® Washer, and freshwater distribution supply hub. The plant is capable of producing up to four products. For example, concrete suppliers may use it to produce coarse aggregate, pea gravel, a blended combination of the two, and a C33 sand off the screw.

The wet Guardian Screen includes spray bars on all three decks to wash out dust and convert the sand to a slurry for feeding the sand screw. Superior’s patented Aggredry Washer separates any clays, dirts and fines and moves the good sand to an integrated dewatering screen. Sand discharges with a moisture content as low as 8 %, making it an instantly salable product. “Our Fusion Platforms are compact for smaller footprints, offer convenient maintenance features, and integrate seamlessly with Superior’s crushing, screening, washing and conveying products,” says product manager, Mark Crooks. “Each configuration can be customized to suit the application, includes plug and play electrical, is scalable to future expansions, and includes plenty of space for maintenance tasks.” The packages are optimized for efficient shipping by road flatbed or ocean container.

Design of new portable plant extends life of HSI crusher wear parts

The brand-new Portable Sentry® HSI Closed Circuit Plant

The brand-new Portable Sentry® HSI Closed Circuit Plant

© Superior Industries

Superior Industries says its brand-new Portable Sentry® HSI Closed Circuit Plant is equipped with the ability to process recycled concrete, reclaimed asphalt, and pit run materials into valuable salable products. From a single feed, owners and operators will be able to produce up to four unique products. The closed circuit crushing and screening arrangement includes a 4250 Superior brand Sentry® Horizontal Shaft Impactor (HSI). It’s fed by a 48×18 Intrepid Vibrating Grizzly Feeder, which is equipped with interchangeable grizzly cassettes (bars, fingers or punch plates) to accommodate multiple applications.

Additionally, a 2-deck Anthem® Inclined Screen screens up to three material sizes. Returning material is fed back to the HSI via a patent pending recirculating conveyor, which centralizes the feed for full utilization and extended wear life of the crushers blow bars. Onboard, the cross conveyors are universally designed to be interchangeable, which means owners invest in fewer conveyors since they can be mixed and matched throughout the plant. “We’re a vertically integrated, single source designer and manufacturer of wheeled plants including all of the processing equipment, conveyors and components,” says Matt Voigt, the product manager for Superior’s portable plants. “This plant is 100 % Superior, which allows us to fine tune and customize all the equipment and components for greater performance, improved portability, and easier maintenance.”

The plant is equipped to accommodate line power, but can also be outfitted with a diesel drive genset unit. Its transport weight, dimensions and axle configurations make it permissible for road travel throughout all of North America. Along with 250-tons of other products, Superior’s new Portable Sentry® HSI Closed Circuit Plant will be shown in Silver Lot booth #5006 at CONEXPO-CON/AGG 2023.

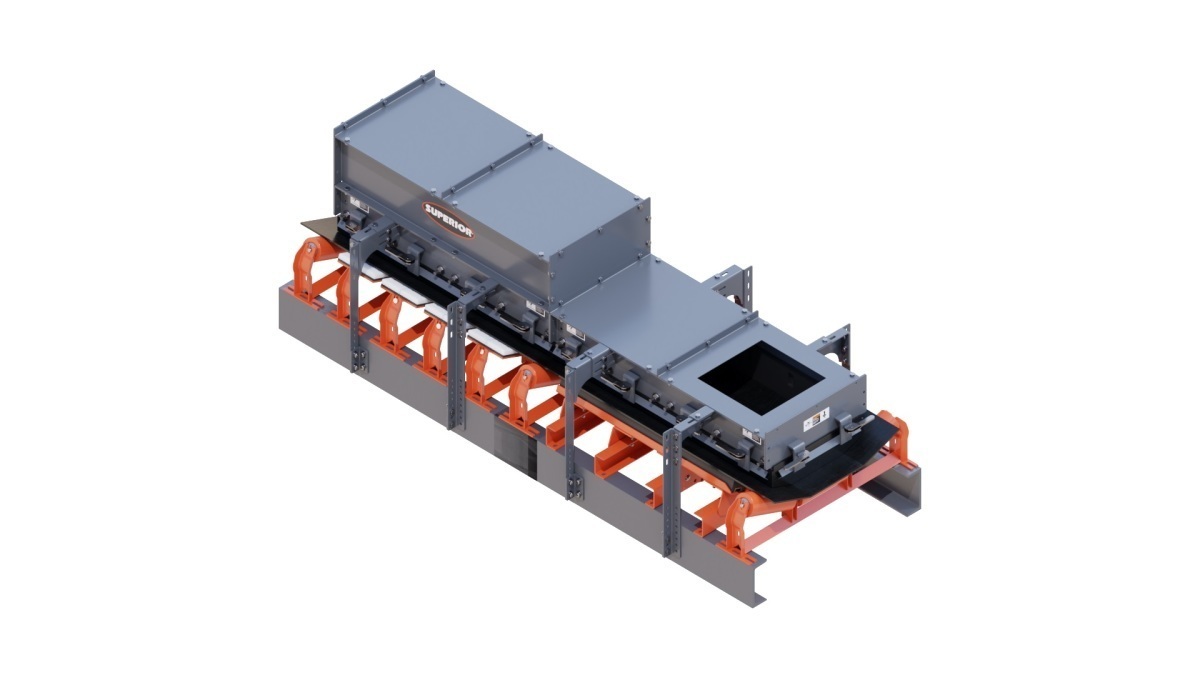

Updates to belt cleaners will reduce maintenance time

The Exterra® Conveyor Belt Cleaners will reduce time required to maintain the scraping systems

The Exterra® Conveyor Belt Cleaners will reduce time required to maintain the scraping systems

© Superior Industries

Superior Industries, Inc. made some tweaks to its Exterra® Conveyor Belt Cleaners, which will reduce time required to maintain the popular scraping systems. First, a new fast-acting click tensioner is available for the primary and secondary models. After installation, operators simply twist the tensioning unit for a prescribed number of times to set proper force. Click count instructions are conveniently labeled on the aluminum housing that protects the springs.

Second, Superior’s SFL scraper models are now manufactured with a special extruded tube. It’s designed to house the patented springs and seal them from fugitive material. The abbreviation SFL means “Set for Life”. Exterra Belt Cleaners with this SFL option require tensioning just once at the time of installation. Accurate tension is maintained automatically – with no required maintenance – for the entire life of the blade.

Third, Superior’s conveyor components engineers recently completed lab and field testing on a proprietary new mix of polyurethane, which is poured into molds to form the blades. This longer-lasting material is also more flexible, which endures beating from belt splices and wears more effectively. All blades are developed in-house by Superior.

There are several models of Exterra Belt Scrapers in both aggregate and mine duty constructions. Blade widths are available up to 2590 mm. Along with 250-tons of other products, Superior’s complete line of Exterra Belt Cleaners will be shown in Silver Lot booth #5006 at CONEXPO-CON/AGG 2023.

Brand new skirting system controls conveyor dust emissions

Brand new modular skirting system

Brand new modular skirting system

© Superior Industries

Superior Industries recently completed development of a brand new Modular Skirting System. The easy to install accessory controls dust and prevents spillage within conveyor load and transfer zones. “Our crews visit and collect data from thousands of conveyor systems each year and we figure about half of them would benefit from material containment components,” says Paul D. Schmidgall, chief engineer in Superior’s conveyor components division. “That’s one out of every two conveyors spilling valuable material, spewing harmful dust, and creating unsafe work environments.”

The new Skirting System retrofits to any brand of existing structure with little or no field fabrication. Two sets of adjustable legs aid in this universal installation. Additionally, easy to adjust clamping mechanisms are used in place of nuts and bolts to hold skirtboard rubber tight against the belt. An optional stilling zone is available to accelerate the settling of dust while material is moving inside the system. Superior’s Modular Skirting System is sold in 1.5 m sections for conveyor belt widths up to 1728 mm. Along with 250-tons of other products, this new Skirting System will be shown in Silver Lot booth #5006 at CONEXPO-CON/AGG 2023.

Best performing idler bearing seal showcased at CONEXPO

Titanium idler bearing seal

Titanium idler bearing seal

© Superior Industries

Superior Industries exhibited the industry’s most modern, longest-lasting conveyor idler bearing seal when it showed off its Titanium™ Seal at CONEXPO-CON/AGG. Several years ago, Superior’s engineers started a project to improve the manufacturer’s standard idler seal. Today, the standard idler seal is new and improved, but a premium seal design was also discovered along the way. It’s achieving supreme performance in some of the grittiest, wettest, most troublesome idler applications. “Design analysis for dozens of iterations were performed in our lab and some of those drafts graduated to real world settings within various quarries and pits,” says Mary Erholtz, Superior’s vice president of marketing and conveying product manager. “When we tallied the scores, it was obvious that our Titanium Seal lasted longer than any other prototype or competitor bearing seal we tested.”

After three years on the market, Superior’s Titanium Seal is earning a reputation for improving conveyor roller service life by as much as 40 %. However, that data is still growing – says Superior – as many of the first installations of Titanium Seals are still performing well. Availability is optional for all of Superior’s CEMA C, D, and E steel idlers, Moxie® Rolls, rubber return and impact rolls, self-aligning idlers, and Urathon® Return Rolls. The configuration of the Titanium Idler Bearing Seal, specially designed to reduce the penetration of fugitive moisture and fines, is patented.

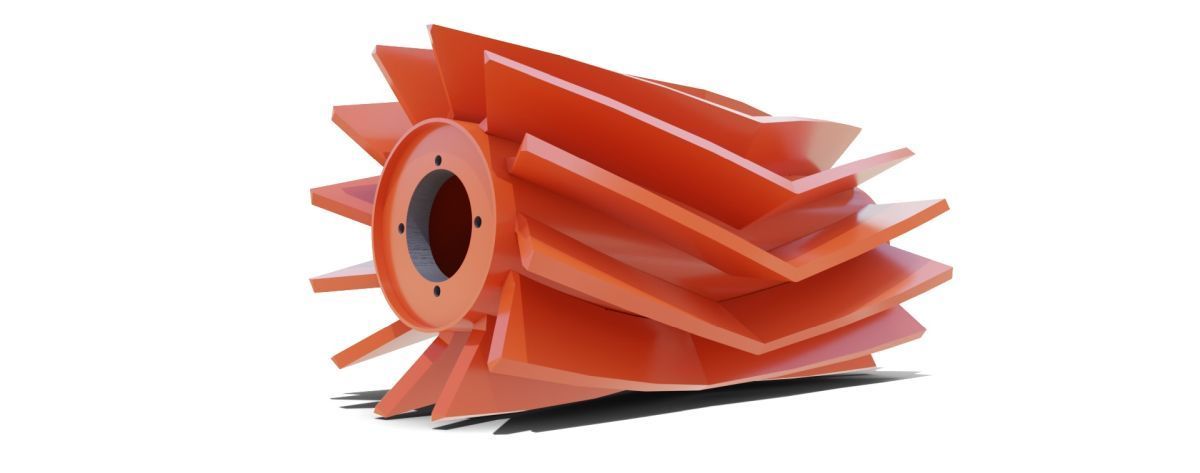

Chevron® Pulley Has New Look At CONEXPO

Chevron wing pulley

Chevron wing pulley

© Superior Industries

Superior Industries revealed a new look for its well-known Chevron Wing Pulley at CONEXPO-CON/AGG 2023. The CEMA-rated model is now designed and manufactured without a rounded cap on the wings. “Users are going to get the same benefits of the original design, but the CEMA class gets a bit of a price reduction without that rounded bar,” says Mary Erholz, vice president of marketing and conveying product manager at Superior. “It’s also going to increase the service life of Chevron Pulleys, since the bare wings offer so much more wearable material.”

The v-shaped Chevron Pulley revolutionized expectations for wing performance after being invented by Superior in 2007. Traditional straight wing pulleys were always prone to trapping material, bending prematurely, and notorious for damaging conveyor belting. The Chevron Pulley’s unique v-shape offered never before seen benefits:

· Deflects oncoming fugitive material

· Fewer rocks trapped between wings

· No trapped rocks to puncture belting

· Constant contact between pulley and belt reduces noise

· Less abusive to belt splices and clips

CEMA Duty Chevron Pulleys are manufactured in diameters up to 914 mm and face widths up to 1980 mm. Mine Duty, Super Duty, and custom engineered classes are also available.

Silver Lot booth #5006