New crushing method

27.06.2024A new type of crushing method gives ores time to react and break down along the natural boundaries of different minerals during slower compression. In a new study, the application of this method for crushing and dry beneficiation of graphite yielded promising results. The development of the mining sector is now strongly oriented towards sustainable solutions.

Laboratory-scale CCC crusher at Oulu Mining School

Laboratory-scale CCC crusher at Oulu Mining School

© University of Oulu / Niina Paasovaara

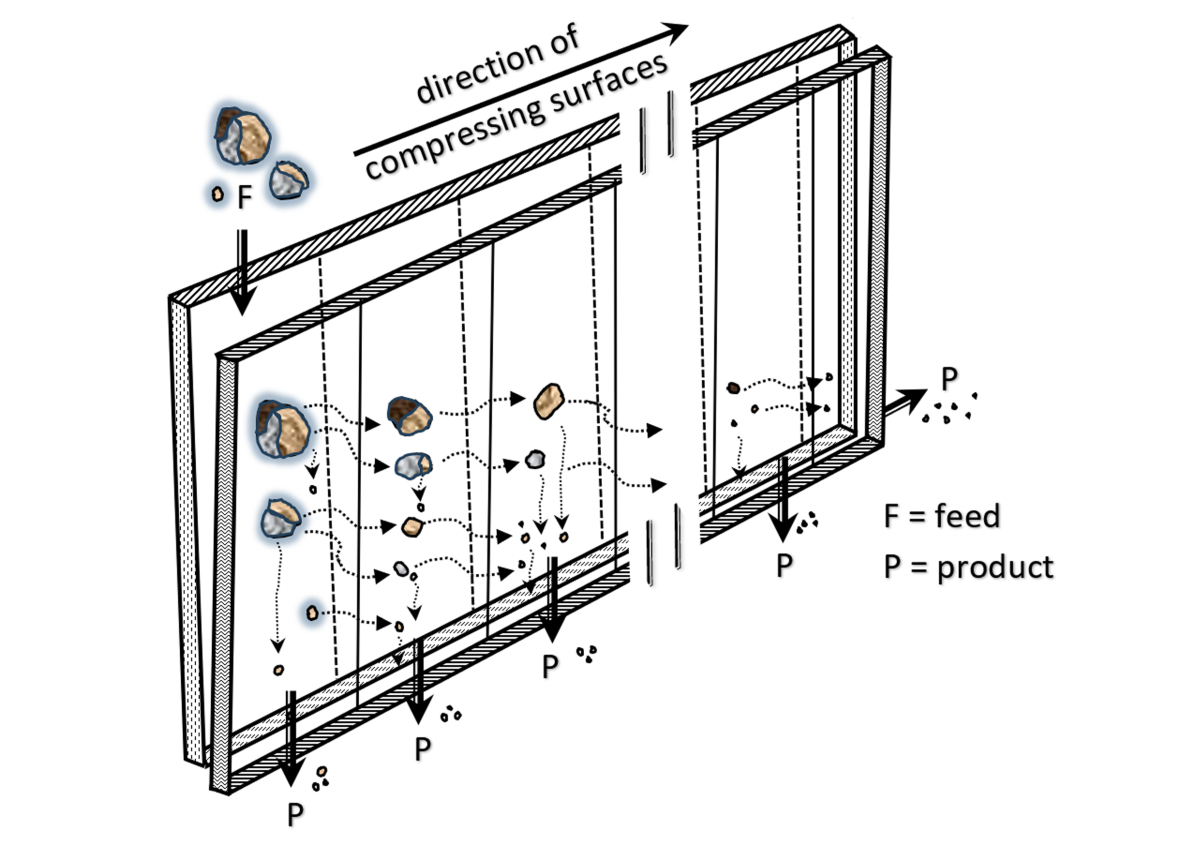

Continuously Compressing Crushing (CCC) method aims to separate valuable minerals from non-valuable minerals more cleanly by exploiting the grain boundaries and micro-cracks of different minerals.

Traditionally, graphite has been processed using wet grinding, a water- and energy-intensive process. A study published in the prestigious journal Minerals Engineering presents the application of CCC for graphite processing, which promises revolutionary savings in water and energy use. CCC was for the first time tested on natural ore samples in a study by the University of Oulu; Finland and involving the University of Eastern Finland and the South-Eastern Finland University of Applied Sciences (Xamk).

"With the growing demand for high-quality graphite in lithium-ion battery production, the potential of the CCC method of producing coarse grained graphite flakes is particularly important. Coarse grained graphite flakes are highly sought after in various industrial applications due to their excellent quality and purity. This new advance will support the green transition and the development of electric vehicles, for example," said Professor Shenghong Yang of the Oulu Mining School at the University of Oulu.

"An important advantage of CCC over conventional methods is that no water is needed, so the method is completely water-free, which reduces the negative environmental impact," says Niina Paasovaara, Doctoral Researcher at the University of Oulu. "In addition, it was already proven in the 1950s that slow compression is the most energy-efficient way to break the ore material, so it is surprising that the method we are refining now has not been adopted earlier."

The operating principle of the new CCC method

The operating principle of the new CCC method

© University of Oulu / Niina Paasovaara

Traditionally, rock is chipped as finely as possible, which easily leads to overgrinding of particles, makes further processing difficult and produces a lot of harmful dust. The new method produces a rougher and cleaner crushing product with a larger surface area, which in many ways facilitates the next steps of the beneficiation of valuable minerals. Read in Finnish more about the inventors of the laboratory-scale CCC crusher: New crusher developed for the mining industry (news, 2020).

"Developing graphite crushing technology is a step towards a more sustainable mining sector. In the future, the water and energy-saving crushing method will be tested for other types of ore containing critical raw materials. There is still a long way to go before the new crushing method can be applied on an industrial scale. It is also important to train new professionals for the mining industry that is facing a constant labour shortage," Professor Yang reminds.

"In further research, we will focus on further proving the energy efficiency at different stages of the crushing process," Paasovaara plans. The method is also linked to an ongoing green chemistry research, which uses new green flotation chemicals to concentrate valuable minerals, in collaboration with the School of Pharmacy at the University of Eastern Finland. "The aim is to make the whole process of crushing, grinding and beneficiation of ore minerals water and energy efficient, and less waste producing. Together with the new flotation chemicals, the CCC method will ensure the cleanliness of green energy transition in the whole ore beneficiation process," Paasovaara continues.

The new research article was published in April 2024: Paasovaara, N., Hartikainen, S., Peräniemi, S., Kuopanportti, H., & Yang, S. (2024). Continuously compressing crushing towards a dry processing method, a testing for graphite ore. Minerals Engineering, 212, 108713: https://doi.org/10.1016/j.mineng.2024.108713

The research is supported by the K.-H. Renlund Foundation and is part of the European Regional Development Fund funded project "HUGGER” – energy-efficient crushing of bio and mineral materials | Xamk .