MINExpo 2024: Martin Engineering unveils 6 new equipment designs

09.09.2024Martin Engineering will feature six new product designs in its booth at MINExpo 2024 in Las Vegas. The friendly Martin team invites attendees to stop by booth #4315, right by the entrance to the Central Hall of the Las Vegas Convention Center on Sept 24 – 26th to see some of the latest innovations in belt cleaners, conveyor enclosure technology and flow aids. Coming directly from the company’s Center for Innovation, these heavy-duty (HD) and extra-heavy duty (XHD) accessories are designed to significantly improve efficiency while reducing dust emissions and offering safer maintenance/replacement. The result is greater productivity with less labor for a lower cost of operation.

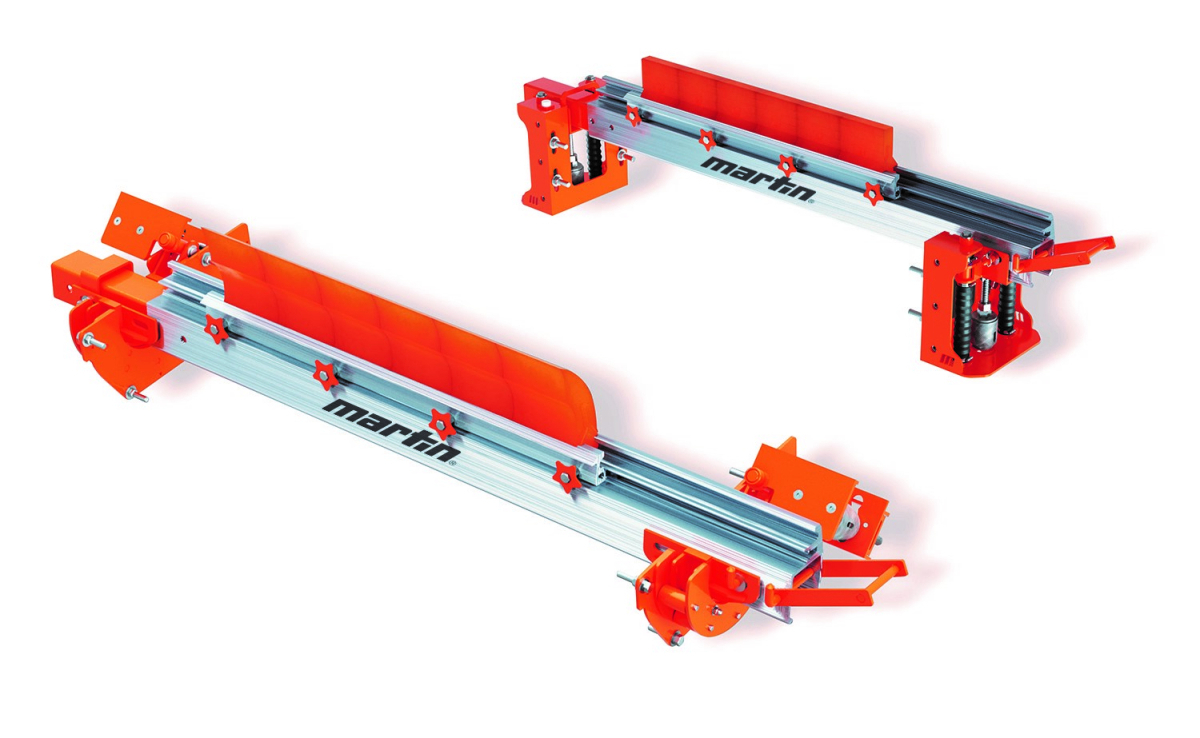

The Martin Engineering booth will feature helpful information and several products

The Martin Engineering booth will feature helpful information and several products

© Martin Engineering

“Martin is celebrating its 80th anniversary by rolling out some excellent new products that extend equipment life, improve safety and reduce maintenance, while also being better for the environment,” said Dave Mueller, Conveyor Products Manager for Martin Engineering. “We’re excited to be able to display and demonstrate several products at the booth and give visitors an idea of their performance in real-world mining applications. All the products have been thoroughly field tested to satisfy Martin’s high standard of quality and meet our Absolutely No Excuses Money Back Guarantee.”

Game-changing belt cleaners

Primary and secondary conveyor belt cleaners are going through a design renaissance as of late. Martin’s engineers have worked diligently to make installation and servicing easier and safer with less environmental waste.

The Martin® EcoSafe Primary and Secondary cleaners offer new safety and environmental features

The Martin® EcoSafe Primary and Secondary cleaners offer new safety and environmental features

© Martin Engineering

Martin® ECOSAFE™ Primary and Secondary Cleaners XHD withstand heavy-duty environments while using less urethane in their construction and mounted on a safe-to-service assembly with easily swapable individual cartridges. The design allows the majority of the urethane to be used for the blade and less is used at the support base which features a removable and reusable metal insert. Using less urethane reduces waste while external servicing allows for easier and faster maintenance.

The CleanScrape® primary and secondary cleaners revolutionized conveyor belt cleaning with 4 times the equipment life of standard urethane blades and eliminating the need for tensioning after installation. The next iteration is the Heated CleanScrape® Primary Cleaner which is heat-traced within the blade making it ideal for harsh sub-zero climates where frozen material buildup can affect performance and cause unnecessary downtime.

Requested by customers, the mining-grade Martin® UBX Secondary Cleaner is designed as a longer lasting and user-friendly alternative to similar units on the market. Intended for wider and faster belts, the new Martin Engineering blade is made entirely of urethane or urethane with an embedded cleaning element that is more robust and longer-wearing than comparable blades on the market. The blade is held snugly to the belt by a mechanical spring tensioner as opposed to the competitors’ troublesome air-supplied tensioners which are unreliable, onerous to maintain and expensive to operate. The result is a more economical unit with longer lasting performance and less maintenance.

Wrapping up the new secondary blade offerings are the Martin® SQC2S™ Cleaner with Orion HD and XHD Blades. Following the successful introduction of the standard model, the more rugged version for wider and faster belts is engineered to handle the most punishing applications. A two-tiered tensioning system with a spring tensioner on the assembly and another rubber tensioner on the blade attachment ensures the urethane and tungsten carbide blade needs considerably less monitoring and tensioning. This low maintenance approach is further supported by the attached polypropene deflector shield to mitigate buildup and usher material away from the mainframe. An important safety feature is the slide-in/slide-out design which allows service and blade replacement to be performed outside the conveyor structure.

The Martin® Urethane Skirting seals the transfer chute enclosure to prevent dust and spillage

The Martin® Urethane Skirting seals the transfer chute enclosure to prevent dust and spillage

© Martin Engineering

Enclosures and dust control

While maintenance access and safe monitoring are vital, so is retaining a sealed environment to control airflow and suppress dust emissions. The Martin® Magnetic Inspection Door is a durable two-part design with a urethane shield and a strong magnetic seal that covers and protects a monitoring and maintenance space on the enclosure. Keeping the dust inside, it is easily pulled back for inspection or, during scheduled shutdowns, pulled all the way down or off for improved access.

The Martin® Urethane Skirting is a long-lasting wear strip placed outside of the skirtboard of a conveyor loading zone to seal the enclosure and prevent spillage and dust emissions. Produced to the belt’s specific trough angle, the urethane strip offers less friction on the belt edge of high-speed belts than rubber skirting for a longer belt life and less damage to the belt edge.

Flow technology

In addition to the new equipment, visitors will see how the superior design of Martin Engineering products like Martin® Air Cannons and Industrial Vibrators can significantly improve the material flow through a system. From choke points like silos and hoppers to screening and separators, strategically placed flow accessories prevent unscheduled downtime and improve safety by preventing manual clearing of obstructions.

A Martin expert draws out a quick sketch to help an attendee visualize the solution

A Martin expert draws out a quick sketch to help an attendee visualize the solution

© Martin Engineering

Mueller said: “Technical experts with knowledge and experience in the mining industry will be manning the booth. We like to think we’ve heard and seen it all, but MINExpo is always full of surprises, so we’d love to hear your story. You never know, perhaps we can offer some wisdom to help solve the issue.”

Booth #4315