Metso’s Sorocaba foundry and rubber factory in Brazil has received carbon-neutral certification

01.11.2024In July 2024, Metso’s Sorocaba foundry and rubber factory in Brazil received carbon-neutral certification in line with PAS 2060:2014 standard from an independent third-party, BSI. The supply chain operations are pivotal to Metso’s overall CO2 footprint, with the Sorocaba foundry and rubber factories accounting for around 20 % of Metso’s own operation’s CO2 emissions.

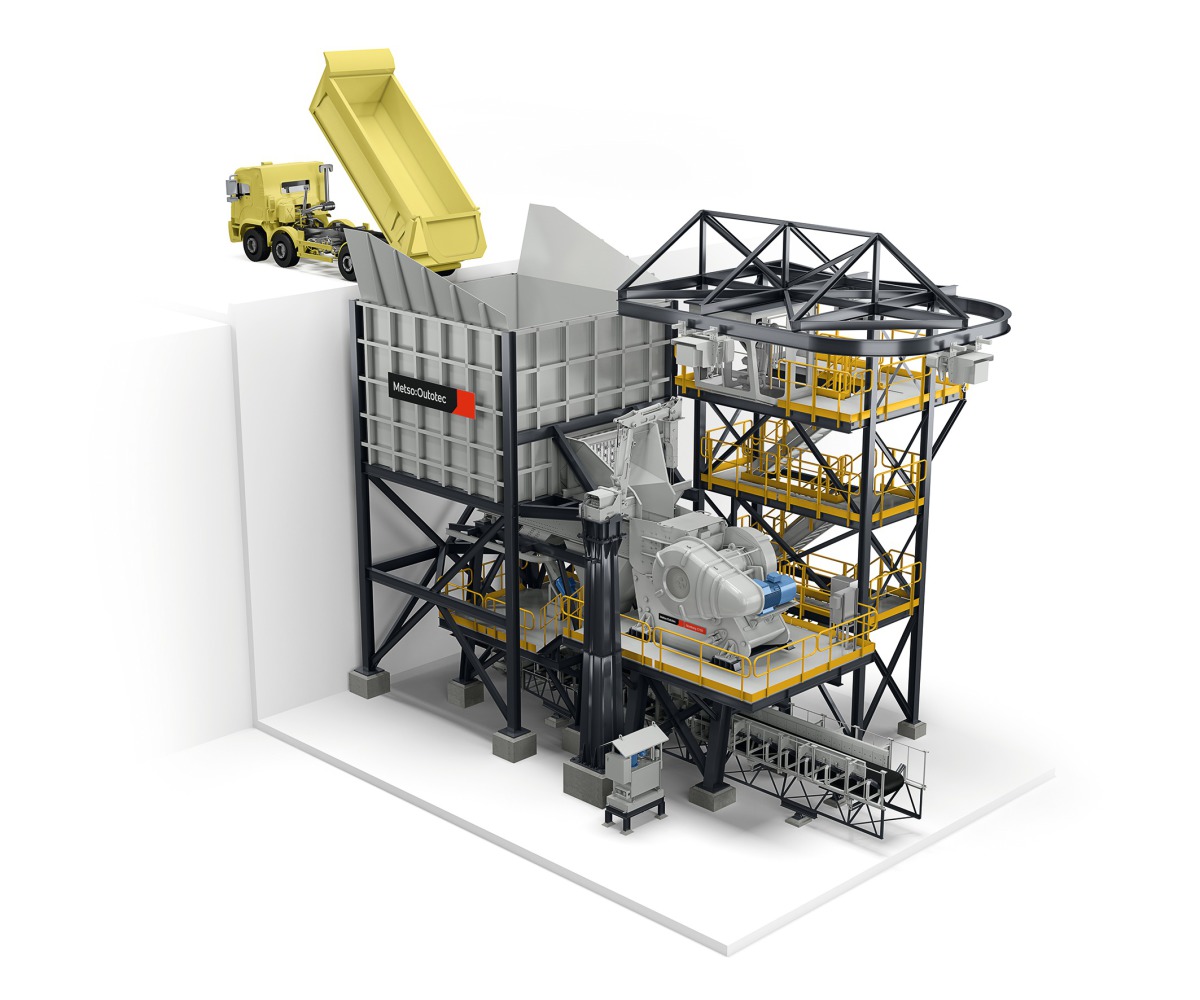

Metso Sorocaba site

Metso Sorocaba site

© Metso

“Metso aims to achieve net zero by 2030 in its own operations, and the certification now obtained is a step towards the set goal. Carbon neutrality is more difficult to achieve in highly energy-intensive foundry operations and our customers increasingly seek evidence of our emissions reductions to help them meet their own ambitious climate objectives. The Carbon Neutral verification aids our customers in reducing their supply chain emissions. We want to be a sustainable partner for our customers and the certificate is a great example of making tangible actions”, says Heikki Metsälä, President, Consumables Business Area.

The most significant initiative towards acquiring the certificate was implemented during the first quarter of 2023 when the Sorocaba foundry and rubber factory partnered with a local supplier for biomethane sourced Gas Renewable Energy Certificates (GAS-RECs) enabling the units to zero their remaining CO2 emissions from 2023. In addition, other environmental initiatives following plans towards net zero were implemented.

The improvement actions in Sorocaba, one of Metso’s biggest production hubs, will continue in many fronts including investment to replace the existing gas boiler with an electric one in its rubber factory and a joint effort between screening manufacturing, foundry and rubber factory to increase own renewable energy production.

“This certification is the latest of our efforts to support our customers in their sustainable mining ambitions in South America. This year we have also opened a new logistics and distribution centre as well as introduced a unique circularity solution for mill liner recycling in Chile”, says Marcelo Motti, Vice President, Sales and Service, Brazil, Metso.

Metso’s Sorocaba manufacturing operations include a foundry and a rubber factory, that were now certified, as well screening equipment manufacturing, pumps manufacturing and a service hub. Today, Metso has approx. 1700 employees working in production, sales, and field service in Brazil.

Read more about Metso’s sustainability targets here .