Metso’s pCAM plant for optimized precursor cathode active material generates positive interest among customers

14.11.2024Metso launched the Metso pCAM plant, an intelligent solution for the manufacturing of precursor cathode active material, in June 2024. The Planet Positive-certified solution, used in the production of lithium-ion batteries, has received exciting feedback from customers.

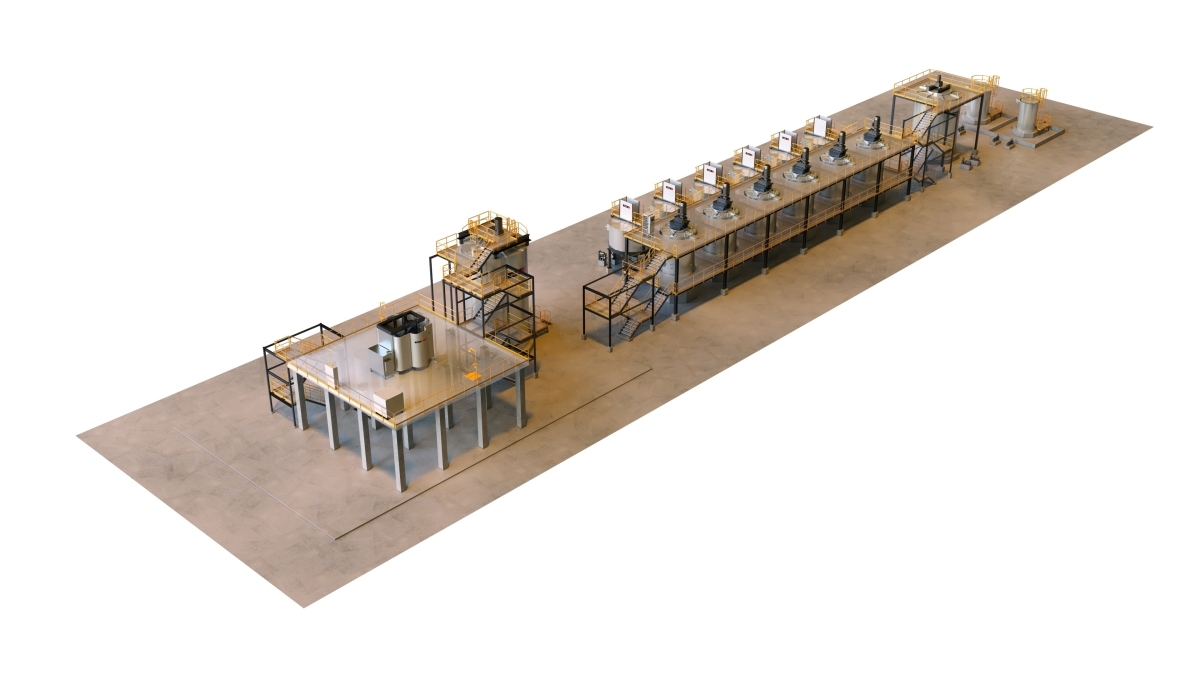

Metso pCAM plant

Metso pCAM plant

© Metso

“Currently, we are involved in discussions with several pCAM producers in North America, Australia and Europe. The discussions have ranged from the delivery of complete plants to supplying certain key technology, like reactors and plant automation, for planned or existing plants. We have several customer projects and pilot campaigns on-going,” says Markus Koponen, Technology Manager, Precursors at Metso.

According to Koponen, the feedback from customers has been very positive: “Our innovative reactor technology and advanced process control are seen as critical enablers for a more sustainable and economically viable pCAM production. In addition, our ability to support customers across the entire process, including selection and in-house testing, process design and piloting of materials recovered from battery black mass is considered a value-adding benefit.”

Metso is the first Western supplier able to deliver a pCAM plant with proprietary technologies for the manufacturing of premium precursor cathode active material. At the core of the plant’s innovative design is the OKTOP® reactor. It enables high throughput with reduced floor space for batch, semi-batch and continuous operation with one reactor set-up, and provides improved yield thanks to advanced process control and online analyzers.

Based on the Life Cycle Impact Assessment (LCIA), the Metso pCAM process features remarkable sustainability benefits reducing water consumption by ~52 %, CO2 emissions by ~31 % and power by ~27 %.”

As a strong and reliable partner for battery minerals development projects, Metso can deliver the whole production process – from mine to battery materials, and recycling of black mass – complemented with world-class service support.

More information on Metso pCAM plants is available here.