Metso to deliver energy-efficient Vertimill® and HIGmillTM regrind mills to Reko Diq copper-gold project

31.01.2025Metso has received an order for Vertimill® and HIGmillTM regrind mills for the Reko Diq copper-gold project in Pakistan. The order, which also includes apron feeders and vibrating feeders, is part of the comprehensive equipment delivery frame agreement announced on August 14, 2024. The order value of the regrind mills and feeders is approximately € 50 million, and it has been booked in the Minerals segment’s 2024 fourth-quarter order intake.

Reko Diq plant layout for Metso regrind mills

Reko Diq plant layout for Metso regrind mills

© Metso

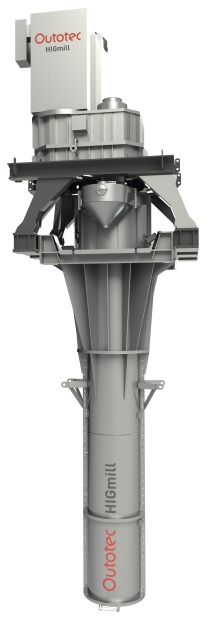

“Following an innovative and collaborative test work campaign, a two-stage regrind circuit consisting of a Vertimill® and a HIGmillTM operating in series was selected to optimize the overall energy-efficiency and operating cost. In this solution, the robust feed particle size capability of the Vertimill® is optimally combined with the efficient fine grinding and particle conditioning of the HIGmillTM,” says Bjorn Nielsen, Vice President, Stirred Mills and HPGR at Metso.

Metso’s stirred milling technologies portfolio consists of Vertimill®, HIGmill™, and Stirred Media Detritor (SMD) mills. These mills are based on gravity-induced and fluidized technologies, allowing for an optimum equipment solution for all comminution circuits in secondary, tertiary, fine, ultrafine, regrind, and lime slaking applications. Metso has over 50 years of experience in developing, testing, and delivering stirred mill technology, including over 500 installations worldwide. All stirred mills are part of the Metso Plus offering.

Read more about Metso stirred mills offering here .