Metso Outotec TankCell® range continues to set the industry benchmark in flotation

07.11.2022Metso Outotec has been re-introducing its comprehensive TankCell® offering, which is the largest of its kind on the market. Since the 1990s, Metso Outotec has delivered nearly 8000 TankCell® flotation cells to mining customers around the world.

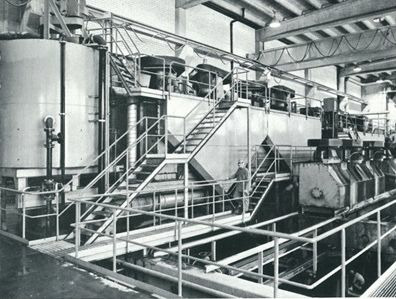

Metso Outotec TankCell e630

Metso Outotec TankCell e630

“The energy-efficient TankCell® flotation cells are part of our Planet Positive offering and are designed to provide optimal metallurgical performance sustainably. All components as well as electrical equipment have been selected for maximum availability and operating life. When combined with the Concorde CellTM, customers can unlock the potential for even further improved performance. Higher recovery, selectivity and final concentrate grade are just a few of the benefits. On top of this, we have a comprehensive automation, services and modernization offering to support our customers’ flotation process improvement and optimization needs,” explains Antti Rinne, Vice President, Flotation at Metso Outotec.

Innovative design provides unmatched flotation performance

The wide range of TankCell® sizes, from 5 to 630 m3, enables an efficient and economical plant design with high availability and reduced plant footprint for any application.

The units are equipped with the FloatForce® mixing mechanism, which provides improved flotation hydrodynamics and pumping performance at high air dispersion rates. Thanks to this innovative mixing mechanism, particle recovery in the flotation cell is very efficient while power consumption and the risk of sanding is reduced. Metso Outotec is working on exciting new developments in the innovative FloatForce® technology and expects to introduce the next-generation mixing mechanisms soon.

The TankCell® flotation cells come with a wide selection of froth management tools, including different types of launders, optimized level control as well as various intelligent instruments.

Metso Outotec also provides a comprehensive range of services for the flotation units, including, for example, flotation process assessment, flotation inspections, and various types of upgrades and life-cycle services packages for the optimization of flotation cell performance.