Metso Outotec answers to growing demand and doubles screening equipment manufacturing capacity in Brazil

21.06.2023Metso Outotec is celebrating the inauguration of the extended manufacturing capacity of large screening equipment in Sorocaba, Brazil. The total Sorocaba production capacity will grow from 250 to 500 units per year, covering among other things the high-performance energy and water efficient UFS Series™ and BSE Series™ banana screens that are part of the Planet Positive offering.

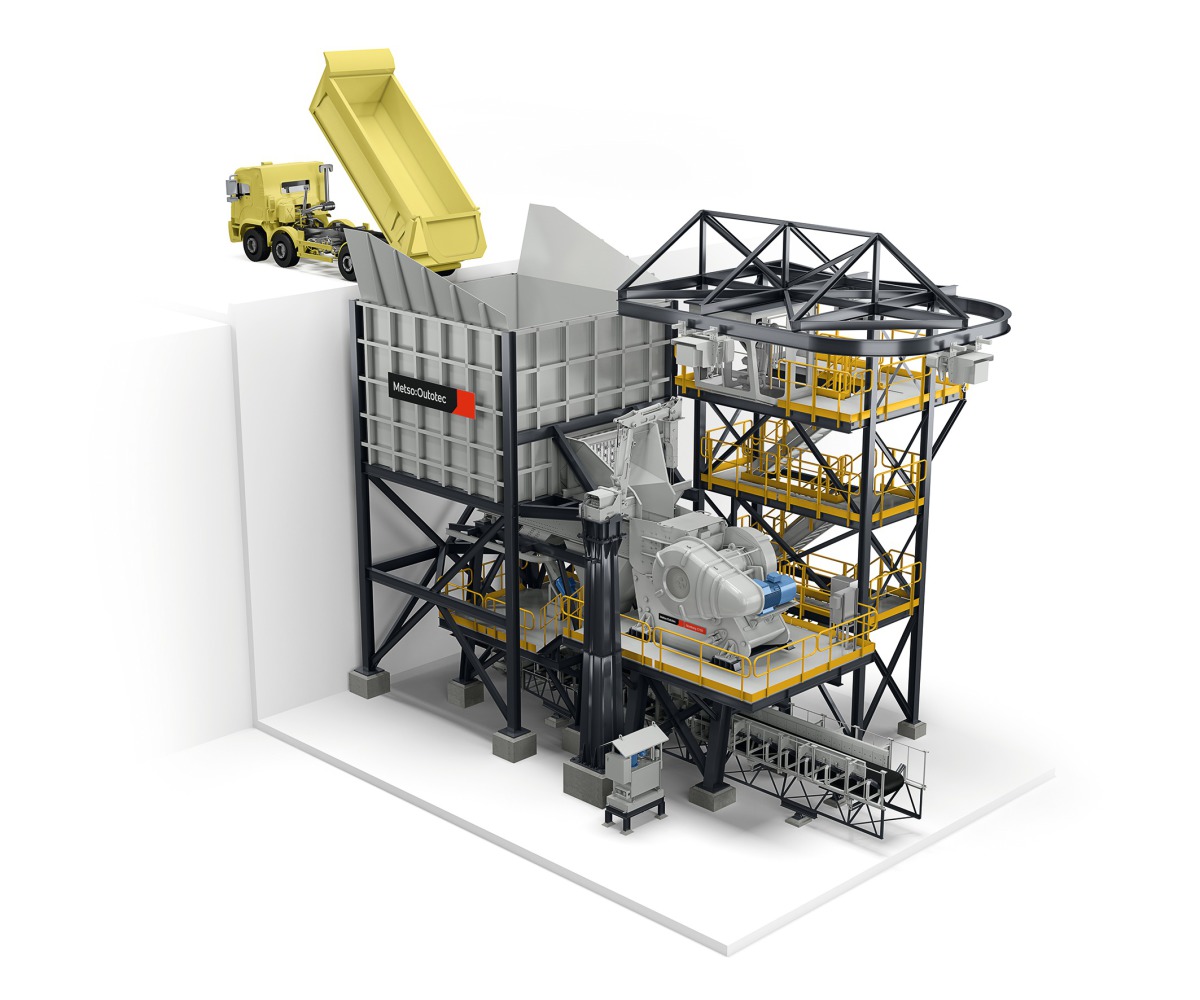

Metso BSE Series™ banana screens are high-capacity screens designed for difficult screening applications

Metso BSE Series™ banana screens are high-capacity screens designed for difficult screening applications

© Metso

Further, Metso Outotec is investing in new fabrication component manufacturing capabilities for screens and screening parts in the same area. The value of the investment is approximately three million euros, and the fabrication unit is expected to be fully operational by the end of 2023. Metso Outotec has also invested in a new injection press for screening media rubber panels which will increase production capacity by 50 %.

“The screening business is one of the growth areas for Metso Outotec. These investments will help Sorocaba become a center of excellence for screening products and they will strengthen our position in South America, offering sustainable and high-quality screening solutions for customers with competitive lead times in a safe and energy-efficient manner,” says Eduardo Nilo, President, South America market area, Metso Outotec.

“Strengthening our end-to-end manufacturing capability in Sorocaba that covers equipment manufacturing, repairs, maintenance services, screening media production and screening product engineering knowledge, enables us to better serve our South American customers and manage the complete product life cycle,” says Eduardo Freire, Vice President, Screening Products, Americas, Metso Outotec.

The screening equipment factory and the new fabrication unit will employ around 35 people. Sorocaba, one of Metso Outotec’s biggest manufacturing and service hubs serving mining and aggregates customers, employs approximately 1700 people.

Additionally, the new screening facility will enable Metso Outotec to service and refurbish large HPGR and HCR technology to meet mining customers’ growing needs for servicing heavy equipment.