Metso introduced upgraded Larox® PF 60 series pressure filter and new machining unit at Filtration Technology Center in Finland

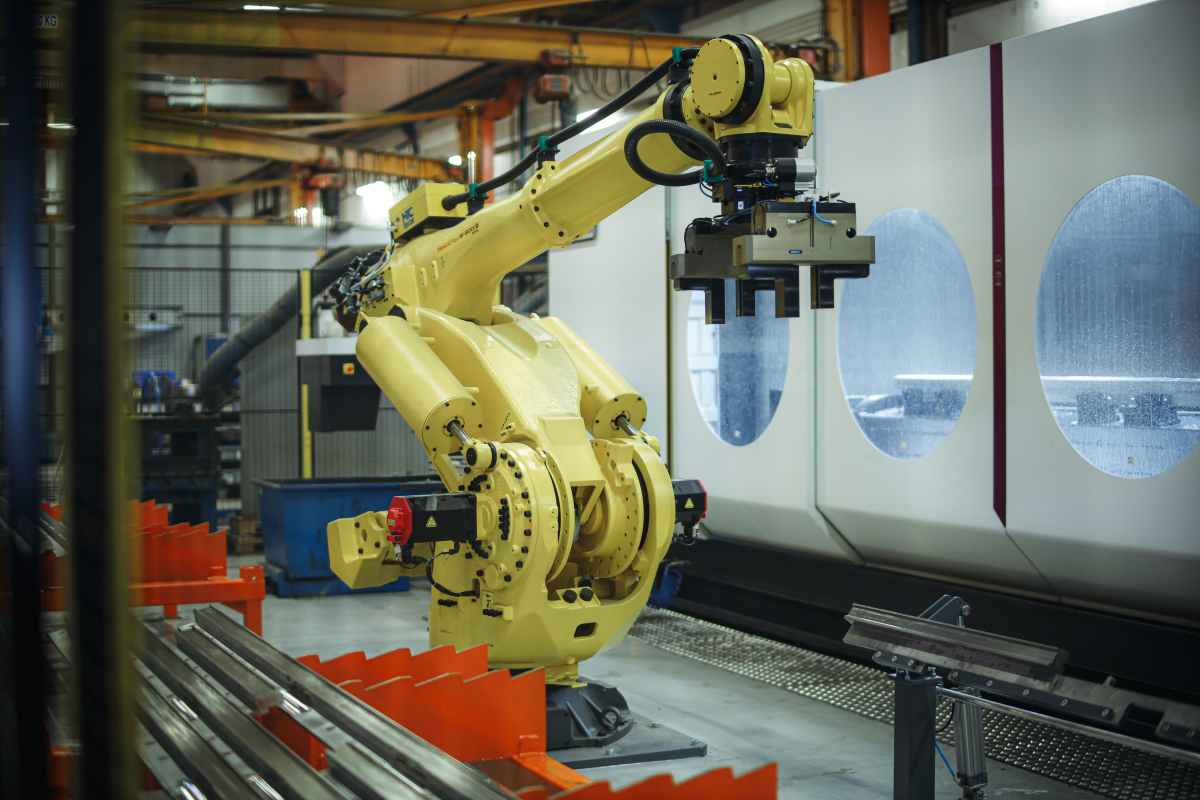

24.10.2024In September, Metso introduced the upgraded Larox® PF 60 series pressure filter at the opening ceremony of the new machining unit at the company’s Filtration Technology Center in Lappeenranta/Finland.

Metso Lappeenranta machining unit

Metso Lappeenranta machining unit

© Metso

“The new version of the Larox® PF 60 series filter marks a step change in the technological development of tower filters. It significantly improves safety, process efficiency and dewatering capacity in mining and other process industry applications, thanks to its novel technological solutions. This upgraded model is fully automated to enable flexible operation for process variations and is future-ready for different plate pack configurations to provide consistent and homogenous filter cake with efficient solids wash,” says Jussi Venäläinen, Vice President of the Filtration business line at Metso.

The Larox® PF 60 series filter is part of Metso’s Planet Positive offering, thanks to its advanced features that decrease water and oil usage by up to 90 % and 75 %, respectively. In addition, it can reduce the need for installed electric power by 25 %. The filter has a compact and open design, which translates to less floor space required and a significant improvement in ease of maintenance. The structure has also been upgraded to meet the latest seismic standards. To ensure optimized lifelong performance, Metso offers a comprehensive service portfolio including remote support.

Metso Larox PF 60 pressure filter

Metso Larox PF 60 pressure filter

© Metso

New machining unit brings more capacity and increased quality

“The investment into a new machining unit at our Filtration Technology Center in Lappeenranta goes hand in hand with the development of the Larox® PF 60 pressure filter and our ambition to offer our customers the best and most responsible filtration technology available. The highly automated machining unit significantly increases our manufacturing capacity and enables the production of high-quality filter components in a safer, more environmentally friendly manner,” explains Tero Tiainen, Director for Filters Manufacturing at Metso.

Besides the manufacturing of advanced filters used in various process industries, Metso’s Filtration Technology Center operates a globally unique Dewatering Technology Center (DTC), which is focused on solid-liquid separation. Metso has carried out more than 14 000 filtration tests and delivered more than 5000 filters for various applications worldwide.

Read more about Metso Larox® pressure filtration solutions here.