Metso expanded its flotation portfolio with modular Concorde Cell™ Plant Units for accelerated results

13.12.2024Metso has expanded its flotation portfolio with modular Concorde Cell™ Plant Units. The new solution consists of prefabricated and pre-installed containerized units, which streamlines the setup process and minimizes on-site installation work. Deployment is safe and rapid, resulting in faster return on investment.

“Concorde Cell™ Plant Units feature a complete sampling and automation portfolio, along with a modular basic design that conveniently accommodates add-ins. This flexibility allows for tailored solutions that meet the diverse needs of our end customers and EPCMs alike,” says Tatu Miettinen, Product Manager, Flotation and Thickening at Metso.

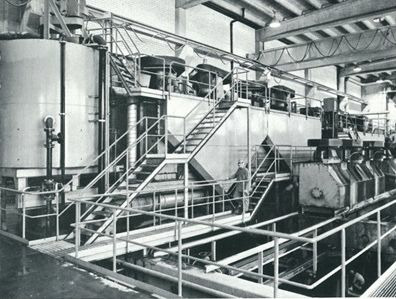

Metso Concorde Cell Plant Unit

Metso Concorde Cell Plant Unit

© Metso

Superior technology for efficient fine and ultra-fine particle recovery

Metso launched the groundbreaking Concorde Cell™ flotation technology for efficient fine and ultra-fine particle recovery for complex ore bodies in 2021. This innovative and sustainable technology has set a new benchmark in high-intensity pneumatic flotation, reducing plant operating costs and contributing to operational sustainability through minimized energy and water consumption per ton of metal produced.

The now introduced Concorde Cell™ Plant Units offer a comprehensive solution encompassing test work and the complete plant unit as well as maintenance and service. The compact unit design integrates pre-designed components, such as connecting launders, pipes, and pump sumps, to ensure a seamless operation and enables reduced footprint and lower plant height, which facilitates easier integration into existing facilities. With this new approach, a shorter order-to-operation timeline can be achieved, allowing for more workshop hours and less sitework and ultimately leading to a quicker return on investment.

Find out more about Metso Concorde Cell™ Plant Units here.